If the Shoe Fits . . . .

Footwear certified as meeting ASTM F2413-11 must first meet the requirements of impact resistance and compression resistance. Then the requirements of additional sections can be met.

- By Sally J. Smart

- Jan 01, 2016

We tend not to think about our feet unless pain is involved, and when that's the case, our feet are all that we can think about! In the workplace this is especially bothersome because pain and productivity are not the best of friends.

There are two major categories of work-related foot injuries in industrial settings. The first category includes foot injuries from impact, compression, and punctures. The second group of injuries includes those resulting from slips, trips, and falls, where footwear may have played a role.

Foot injuries and complications are just as likely in an office setting as they are in an industrial setting, but the problems present themselves in different ways. The following issues aren't necessarily injuries, but rather ailments that can be caused by workplace conditions—aching feet, athlete's foot, blisters, calluses, corns, rheumatism, arthritis, fallen arches, bunions, and sprains. These foot issues can result from standing for long periods of time, especially on hard concrete flooring, or by poorly fitting footwear.

This article focuses on the importance of the fit, form, and function of protective footwear.

Statistics

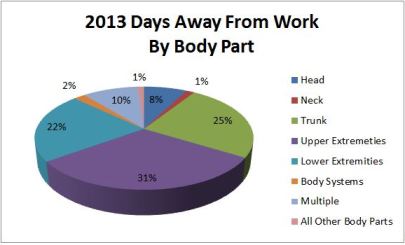

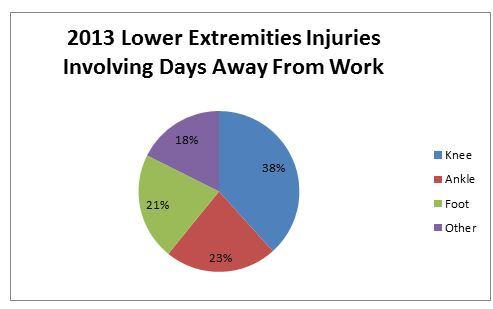

According to the Bureau of Labor Statistics (BLS), of the 917,060 private industry nonfatal occupational injuries and illnesses involving days away from work during 2013, 22 percent (202,280 cases) involved injuries to the lower extremities. More than 89,000 (43 percent) of these cases involved injuries to the ankle or foot.

Source: BLS Nonfatal Occupational Injuries and Illnesses Requiring Days Away From Work, 2013, Table 5, Private Industry

Source: BLS Nonfatal Occupational Injuries and Illnesses Requiring Days Away From Work, 2013, Table 5, Private Industry

Standards

The Occupational Safety and Health Administration requires employers, whenever possible, to eliminate or reduce exposure to hazards through engineering or administrative controls. When such controls are impractical or economically infeasible, personal protective equipment must be used. Protective footwear requirements for general industry are referenced in Title 29 of the Code of Federal Regulations. General PPE requirements are given in 29 CFR 1910.132, and foot protection requirements are in 29 CFR 1910.136.

According to 29 CFR 1910.132(a)(1), PPE must be used whenever an employer's workplace hazard assessment determines that hazards that require PPE are present, or are likely to be present. Per 29 CFR 1910.136(a), "Each affected employee shall wear protective footwear when working in areas where there is a danger of foot injuries due to falling or rolling objects, or objects piercing the sole, and where such employee’s feet are exposed to electrical hazards."

29 CFR 1910.136 incorporates by reference the ASTM F2412-05 Standard Test Methods for Foot Protection, F2413-05 Standard Specification for Performance Requirements for Protective Footwear, and the American National Standards Institute (ANSI) American National Standard for Personal Protection—Protective Footwear (ANSI Z41-1999 and Z41-1991). On March 1, 2005, the ANSI Z41 reference was withdrawn and replaced by the ASTM standards. The ASTM standards were reviewed and updated in 2011.

ASTM F2412-11 (Standard Test Methods for Foot Protection) and ASTM F2413-11 (Standard Specification for Performance Requirements for Protective (Safety) Toe Cap Footwear are the most current footwear consensus standards.

Footwear certified as meeting ASTM F2413-11 must first meet the requirements of impact resistance and compression resistance. Then the requirements of additional sections such as metatarsal protection, conductive protection, electric hazard resistance, static dissipative protection and protection against punctures can be met.

Safety Footwear

Safety toe footwear must contain a reinforced toe section that is capable of withstanding an impact force of 75 foot pounds of energy without deforming the toe area downward to less than 0.5 inches above the footbed for men's shoes and 0.468 inches for women's shoes. This test is conducted by dropping a 50-pound weight from a height of approximately 18 inches. This results in an impact velocity of 117.9 ± 2.4 inches per second and creates energy of 75 foot pounds.

Safety toe footwear also must be capable of withstanding a rolling or compressive force of 2,500 pounds without deforming the toe area to less than 0.5 inches above the footbed for men's shoes and 0.468 inches for women's shoes. This test is conducted by slowly applying a force at a speed of 50 pounds per second until it reaches 2,500 pounds.

Metatarsal protection should be suggested any time potential hazards exist that may result in blunt trauma injury to the metatarsal portions of the foot from falling, moving, or rolling objects or equipment. The metatarsal bones are behind the toes and forward of the ankles on the top part of the foot. Metatarsal protective footwear must be capable of withstanding an impact force of 75 foot pounds of energy without deforming the inside metatarsal area downward to less than 1.0 inch for men's footwear wear and 0.937 inches for women's footwear.

Conductive protective footwear is designed to prevent the possibility of static electricity buildup in the wearer. It must demonstrate a resistance of 0.0 to 500,000 ohms.

Electrical hazard resistant footwear is designed to be a secondary layer of protection against electric shock in the event of accidental contact with an electrical circuit and must withstand the application of 18,000 volts with current leakage of no greater than 1.0 milliampere.

Static dissipative footwear must prevent the buildup of excess static electricity while at the same time providing limited protection against electric shock. It must have a lower level of resistance of 106 ohms and an upper level of 108 ohms.

A puncture-resistant device is placed between the foot and the outsole of puncture-resistant footwear. This footwear must resist a force of 270 pounds without the puncture-resistant device being visibly penetrated. It also must not show any signs of corrosion, delamination, or deterioration after being exposed to a 5 percent salt solution for 24 hours and no signs of delamination of layers or cracking after 1.5 million flexes.

Slips, Trips, and Falls

Both slips and trips result from some kind of unexpected change in contact between the feet and the ground or walking surfaces. This proves that good housekeeping, high-quality flooring, and proper footwear are critical to prevent slips, trips, and falls.

Slips occur when a person's foot loses traction with the ground surface. Common slip hazards include spills of liquid or solid material, wet cleaning methods, a sudden change in floor surface, dusty and sandy surfaces, loose or bumpy flooring, slick floor finishes, weather hazards, and improper footwear.

Trips occur when a person unexpectedly catches his or her foot on an object or surface. In most cases these are low obstacles that are not readily noticed: uneven edges in flooring, loose mats, opened drawers, or cables.

Slip and trip hazards must first be addressed using engineering and administrative controls. When engineering and administrative controls are infeasible or costly and cannot be implemented, then PPE should be considered. Examples include slip-resistant footwear for wet or slippery locations or work boots with high-traction soles for muddy areas.

The degree of a shoe or boot's slip resistance is determined by the coefficient of friction (COF). A higher COF means more slip resistance. Currently, there is not an ASTM standard for sole slip testing. No shoe or boot can claim 100 percent slip resistance, but those with a smaller pattern tread design with sharp leading edges that act as a squeegee provide a better grip.

Fit and Function

Footwear that fits well, is comfortable, and allows you to do the best job possible is a must. Factors to be considered when choosing footwear include:

- Physique and fitness of the wearer

- Intended working position--sitting, standing or walking

- Physical environment in which the footwear will be worn—hot or cold, wet or dry, coarse or smooth ground, firm or soft ground , and the potential existence of contaminants

- Type of safety protection needed

When selecting footwear keep the following in mind:

- The inner side of the shoe must be straight from the heel to the end of the big toe.

- The shoe must grip the heel firmly.

- The forepart must allow freedom of movement for the toes.

- The shoe must have a fastening across the instep to prevent the foot from slipping when walking.

- The shoe must have a low, wide-based heel—flat shoes are suggested.

- A shoe should fit well from the start. Do not expect footwear that is too tight will stretch with wear.

- Feet normally differ in size; have both feet measured and buy footwear to fit the bigger foot.

- Tight socks can cramp the toes as much as poorly fitted shoes.

- Wrinkled socks or socks that are too large or too small can cause blisters.

- Intended footbeds, arch supports, or orthotics must be worn when trying on footwear. The use of any footbed/insole that is different from the original that came with the footwear may affect the protection offered and any risk of injury shifts to the user.

- A general rule of thumb is that a woman's shoe or boot size is two sizes smaller in a man's size—that is, a woman's size 9 would be a men's size 7.

- A men's "D" width is the same as a medium width. A men's "E to EE" is generally the same as a wide width, while 3E is extra wide and 4E is double extra wide.

Replacement guidance:

- If there is evidence of physical damage to the toe and/or evidence of physical damage to the toe area of the impact and compressions resistant footwear, replace it.

- Dispose of metatarsal impact footwear after an impact to the guard has occurred or after the exterior covering becomes torn, exposing the guard.

- Replace conductive protective footwear if it becomes contaminated and/or no longer tests conductive.

- Dispose of electric hazard resistant footwear if the uppers are punctured, cut, or if they show signs of cracking, are imbedded with conductive materials (metal particles, nails, thumbtacks, etc. ), or if wear causes the outsole thickness to noticeably diminish.

- Static dissipative footwear should be worn indoors only, and care should be taken to keep the outsoles clean. Tests for required resistance levels should be performed on a regular basis; footwear that no longer meets the required resistance level should be replaced.

- Dispose of puncture-resistant footwear after an object becomes imbedded in the puncture-resistant device.

Conclusion

If the potential for foot-related injuries exists at your workplace, then you should wear appropriate protective footwear. The footwear must be chosen based on the hazards that are present. Properly selected and fitted footwear increases protection and comfort and in turn improves employee safety and productivity.

References

1. 29 CFR 1910.132

2. 29 CFR 1910.136

3. ASTM F2412-11 Standard Test Methods for Foot Protection

4. ASTM F2413-11 Standard Specification for Performance Requirements for Protective (Safety) Toe Cap Footwear

5. Bureau of Labor Statistics, Nonfatal Occupational Injuries and Illnesses Requiring Days Away from Work, 2013

This article originally appeared in the January 2016 issue of Occupational Health & Safety.