Can Industrial Chemical Exposure Cause Hearing Loss?

It is important to remember that any chemical that is ototoxic is also likely to be poisonous to the kidneys, because the inner ear and the kidneys arise from the same germ layer during embryonic development.

The short answer to the question in the headline is an unequivocal "yes!" There are industrial chemicals in common use that are ototoxic (poisonous to the ears), meaning that they can damage hearing just as easily as industrial noise. However, simultaneous exposure to noise and ototoxic chemicals is particularly insidious because of their synergistic effect.

In order to illustrate a synergistic relationship, let's suppose a given noise exposure is responsible for a 10-dB threshold shift. Let's also suppose that an ototoxic chemical, by itself, can induce a 10-dB threshold shift. If exposure to the noise and ototoxin together results in a 20-dB threshold shift, then we say the combined effect is additive. A synergistic effect, however, is one in which the combined impact of the noise and ototoxin results in a much greater total threshold shift than would be predicted by simply adding together the noise- and ototoxin-related threshold shifts—perhaps a 35- or 40-dB threshold shift may occur. Also, such a threshold shift often impacts a wider range of frequencies. Indeed, a synergistic effect is greater than the sum of its parts, and this observation has been borne out by research involving industrial workers.1

Even if noise levels alone don't seem loud enough to cause hearing damage (e.g., 80 dBA), the synergy with chemicals makes the risk of hearing loss more likely even with noise exposures below the action level. In any environment where chemicals are being used, wearing hearing protection is good practice when noise is present at levels just below the action level, and especially where the work activity requires the use of a respirator. Wearing a respirator is every bit as important as wearing hearing protection when it comes to preventing hearing loss from ototoxins.

Most ototoxins damage hearing through toxic oxidative stress, the same condition caused by prolonged exposure to high noise levels. Oxidative stress is an accumulation of reactive oxygen species (free radicals) brought about by excessive metabolic activity. This condition triggers a form of programmed cell death called apoptosis (the process is depicted in the accompanying graphic). While apoptosis occurs naturally as a part of healthy cell maintenance, a localized avalanche of cellular death—say, within the inner ear—causes extensive damage from which the body cannot properly recover.

In addition to hearing, the inner ear also has the primary responsibility for helping us keep our balance. Unlike industrial noise, ototoxic compounds can affect all of the inner ear structures, including the balance organs—not just the hearing part—putting a person at risk for falls from a general loss of balance, dizziness, or, in severe (but rare) instances, vertigo. It is also important to remember that any chemical that is ototoxic is also likely to be poisonous to the kidneys, because the inner ear and the kidneys arise from the same germ layer during embryonic development. While kidney damage is rare, it can result from a serious complication of chemical exposures and is often presaged by hearing difficulties resulting from the same causes.

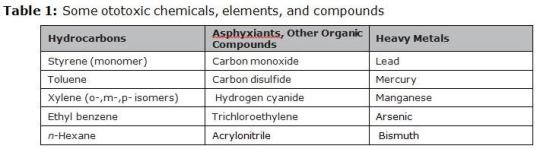

As alluded to earlier, exposure to some industrial chemicals can cause hearing loss without additional exposure to noise. At the top of the list are mixtures containing organic solvents, including benzene-based and aliphatic hydrocarbons (e.g., styrene and n-hexane, respectively) and other organic compounds (e.g., carbon disulfide and trichloroethylene). Phosphate-based chemicals for farming, gardening, and industrialized agriculture, and asphyxiants, such as carbon monoxide and hydrogen cyanide, also can have a profound impact on hearing. So do certain metals, particularly lead, mercury, manganese, and arsenic, including their salts and oxides. In addition to triggering apoptosis through oxidative stress, heavy metals are neurotoxins that attack the nerves that convey signals from the ear to the brain, as well as damage neurons in the brain itself.

Current Exposure Limits in Need of Review

Table 1 lists examples of known ototoxins from several reviews.2,3,4 It is not an exhaustive list. The Occupational Safety and Health Administration (OSHA) and the American Conference of Governmental Industrial Hygienists (ACGIH) have established permissible exposure limits for several of these compounds. However, there is much individual variability in sensitivity and susceptibility, and permissible exposure limits are in need of review.

The following practices are or can be adopted by companies with worker exposures to both noise and ototoxic chemicals:

- Because of the synergistic effect of many chemicals with noise, wearing a respirator and hearing protection together is an ideal defense against hearing loss whenever chemicals and noise are simultaneously present. In fact, if the chemicals to which workers are exposed are known ototoxins, it may be a good idea to require hearing protection whenever a respirator is required and noise levels are between 75 and 84 dBA, inclusive. In order to avoid overprotecting hearing in these situations, low- or uniform-attenuation hearing protectors should be used so that warning alarms can still be heard and speech can be understood.

- Employees exposed to marginally hazardous noise levels (i.e., just below the action level) together with ototoxins should be considered for inclusion in a company's hearing conservation program. The U.S. Army, for example, requires any employee exposed to known or suspected ototoxins to be enrolled in its hearing conservation program, whether or not they are exposed to noise.5

- As recommended by the ACGIH, consider more frequent audiometric monitoring of employees exposed to a combination of known ototoxins and noise.

- Whereas audiometric surveillance is a lagging indicator of hearing loss risk, individual field fit testing is a proactive and preemptive activity that yields leading indicators of efficacy. Fit testing is available for hearing protection just as it is for respiratory protection. Although not mandated for hearing protection as it is for respiratory protection, fit testing an individual’s hearing protection is an OSHA Best Practice6 and can be used in conjunction with respiratory fit testing for workers whose hearing is at additional risk from synergistic exposures to chemicals and noise.

References

1. Bergstrom, B. & Nystrom, B. (1986). Development of hearing loss during long-term exposure to occupational noise. A 20-year follow-up study. Scandinavian Audiology, 15, 227-234.

2. Vyskiocil, A. et al. (2012). A weight of evidence approach for the assessment of the ototoxic potential of industrial chemicals. Toxicology and Industrial Health, 28(9):796-819 (Epub Nov. 7, 2011).

3. Pouyatos, B. & Fetcher, L.D. (2007). Industrial Chemicals and Solvents Affecting the Auditory System. In Pharmacology and Ototoxicity for Audiologists, K.C.M. Campbell (Ed.). Clifton Park, NY: Thomson Delmar Learning, pp. 197 – 215.

4. Morata, T. (2004). Ototoxicity: An issue in hearing loss prevention in the workplace. CAOHC Update, 16(2), 7-9.

5. United States Army (Dec. 10, 1998). Pamphlet 40-501: Hearing Conservation Program. Washington D.C.: Department of the Army

6. OSHA/NHCA Alliance. (2008). Best Practices Bulletin: Hearing Protection— Emerging Trends: Individual Fit Testing. National Hearing Conservation Association. Accessed Feb. 10, 2016, at https://c.ymcdn.com/sites/www.hearingconservation.org/resource/resmgr/imported/AllianceRecommendationForFitTesting_Final.pdf

This article originally appeared in the June 2016 issue of Occupational Health & Safety.