Getting It Right: Creating and Deploying an Effective and Compliant Chemical Safety Training Program

Make sure the methods discussed for detecting the presence or release of chemicals line up with the specific chemicals and hazards you have at your facility.

- By Melissa McCaffrey

- Jul 15, 2019

While employee training is a critical part of OSHA's Hazard Communication Standard (HazCom), it's also an area where employers often fall short and struggle with the basic elements that make training effective, engaging, and, most of all, compliant.

Whether you're establishing a new chemical safety training program or just looking to update your current program to make it more effective, it's critical that you have a solid understanding of your training obligations under OSHA's HazCom Standard. The following is a helpful overview of common training compliance mistakes and misconceptions, along with some best practices to help you avoid them and ensure your employees are getting the most out of your chemical safety training program.

What Information Training Must Cover

Understanding what the HazCom Standard requires for employee training is a critical first step in creating an effective chemical safety training program. This includes:

- The contents of the HazCom Standard itself. This might seem redundant, but employees should know what the standard is and understand that it requires chemical manufacturers to provide safety data sheets (SDSs) and shipped container labels for products shipped to downstream users, and employers to provide them with information about the hazards of the chemicals in their workplace.

- Detecting the presence or release of chemicals. Whether done through use of monitoring equipment or simple observations, such as odors or visible evidence of sheens or stains, employees must know how to detect a chemical release. If you use digital monitors, include information about where they are, what they measure, and how to interpret the readings. And make sure the methods discussed for detecting the presence or release of chemicals line up with the specific chemicals and hazards you have at your facility.

- Physical and health hazards of hazardous chemicals in the workplace. If the hazard is present in your facility, training must cover it. This includes those from simple asphyxiants, combustible dusts, and pyrophoric gases, as well any hazards not otherwise classified.

- How employees can protect themselves from chemical hazards. This includes clear and detailed information on the usage of personal protective equipment (PPE), safe work practices, engineering controls, and any other specific procedures or controls you've implemented.

- Hazard Communication Program details. OSHA expects employees to understand the details within your company’s written HazCom Plan, including the specific management practices for the chemicals at your facility. A key factor here is ensuring that you’ve updated both your written HazCom Plan and training to reflect any changes to your chemical management system.

Who Needs to Be Trained

While many employers do a good job of providing the right training content, they often fall short in identifying all of the workers who need to be trained.

It basically comes down to the question of which employees may be exposed to hazardous chemicals at work. In its "Hazard Communication Guidelines for Compliance" document, OSHA states that it intentionally kept this scope broad and "includes any situation where a chemical is present in such a way that employees may be exposed under normal conditions of use or in a foreseeable emergency." For some employers, this may mean that you need to train all of your employees, while for others it may only include a select group. The important thing is to be familiar with your operations, the job tasks involved, the associated chemicals, and the possible routes of exposure to determine which members of your workforce require training.

Don't forget to include contract and temporary workers. OSHA's recent guidance on protecting temp workers, including its Temporary Worker Initiative (TWI), makes it clear that they expect the staffing agency and the host employer to share the responsibility for worker safety. This means that if you use contract or temp workers at your facility, you as the host employer are responsible for training them about the hazards and HazCom management practices at your facility. Make sure that, among other things, your training includes how to access SDSs, because this can become important very quickly during an emergency.

While the staffing agency should be training its people on general HazCom requirements and on the hazards of chemicals they regularly work with from one job site to another, you should keep open lines of communication with them to ensure that each of you understands the other's roles and responsibilities and that no gaps in training or communication exist.

How to Conduct the Training

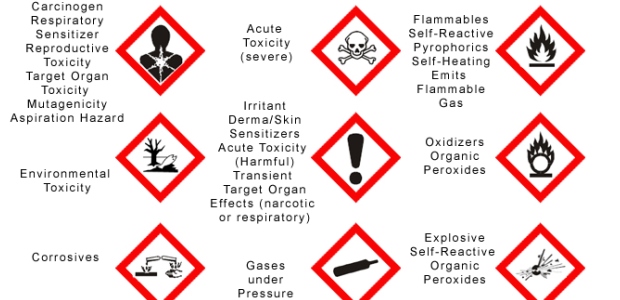

Effective training is done in a language and method that employees understand. Employers that simply conduct their training for the sake of completing the necessary task with little regard of whether the information is being retained will be unable to convince an OSHA inspector that they've met their HazCom training requirements. That's because OSHA feels its adoption of GHS in 2012 has taken the standard from being one that gave workers the right to know, to one that gives workers the right to understand, thanks to harmonized hazard communication information on SDSs and labels and the introduction of pictograms, which use images to convey hazards.

In a guidance document for small business entities, OSHA clarifies that while it does not expect workers to be able to recall and recite all of the data provided about each hazardous chemical in the workplace, it does expect that they understand how to go about getting access to specific hazard information on labels and SDSs, how to read labels and SDSs, and how to access them in their work environment.

So how does this translate into conducting effective training? Let's first look at language. Employers often seem to think they need to train in English, perhaps because they're confusing training requirements with the language requirements for SDSs and container labels. In reality, training must be done in a language that covered employees understand. If most of your employees speak English but some do not, then you must provide training in English to those who do understand it and also in whatever other language(s) your other employees understand. This is an area where on-demand, online training solutions may be helpful, and the top solutions offer a range of course options in multiple languages to help you meet this requirement.

Beyond language, you also need to train employees in a manner they understand. This means you must account for any limitations in literacy level or vocabulary within your workforce. The more employees you have, the less likely it is that a one-size-fits-all training approach will work. For example, training programs that heavily rely only on presentation of written material will not work very well for workers with limited literacy. As a general rule, if you find that you need to provide an employee with regular job instructions in a certain manner to get the points across, you should provide your HazCom training the same way.

One of the most overlooked ways to improve the effectiveness of your training is to adjust the quality of your training objectives. Objectives that are too vague or broad will be difficult to meet. Instead, create more specific objectives with performance conditions spelled out. This way, if you see that employees are missing the mark, you can more easily revisit specific areas of your training to find out why and fix the problem.

How to Document Training

While the HazCom Standard doesn't specifically require employers to document training, it's something they recommend be done and even provide suggestions for what should be documented, including:

- Date of presentation

- Learning objectives

- Training program outline

- Names of participants; employee identification number or Social Security number

- Names of instructors

- Any objective data, such as test results, demonstrating that learning objectives were met

One reason why training documentation is important goes back the need to update training content with any changes made to your chemical management system, including the introduction of new physical or health hazards into the workplace, or after finding evidence that training was not effective or no longer retained. Without the right kind of training documentation, this can be difficult to accomplish.

Of course, maintaining records with this level of detail for all of your workers can be challenging, especially if you have a large workforce or are managing HazCom across multiple establishments. Consider the benefits of using modern EHS software to help assign and track training, which also will help you to easily verify that training is complete and understand when you need to retrain.

Why Avoid the 'Annual Training' Mindset?

Another common misconception about training is that OSHA requires employers to conduct annual refresher training. In reality, OSHA states that employees must be trained before they begin working with hazardous chemicals and whenever a new hazard is introduced into the workplace or there's evidence that training was not effective.

The problem with the "annual training" mindset is it can be harmful to your HazCom program. Training has a way of becoming fossilized; once a year, you dust off your training materials and go through the same motions to train your workforce once again. But let's say that during the last year you've introduced new chemical hazard categories or changed key aspects of your management system. It can be easy to neglect updating your training because you didn't think it was time to do so, and as a result you're now out of compliance with HazCom requirements.

Keeping an Eye on the Big Picture

Chemical safety training ensures workers have the information they need to protect themselves from the hazardous chemicals they work with. But what we're really talking about here is changing people's behavior by replacing unsafe behaviors based on incomplete knowledge of chemical hazards with safe behavior based on accurate hazard information. Effective HazCom training helps accomplish that and, when done well, creates the kind of transparency and two-way communication between employees and management that is necessary to improve your EHS culture.

This article originally appeared in the July/August 2019 issue of Occupational Health & Safety.