The Occupational Safety and Health Act of December 29, 1970, states “An Act: To assure safe and healthful working conditions for working men and women …” Section 5 of the Act titled Duties goes on to state that the employer “shall furnish to each of his employees employment and a place of employment which are free from recognized hazards that are causing or are likely to cause death or serious physical harm to his employees.”

History of and requirements for the Arc Flash Hazard

Analysis

The Occupational Safety and Health Act of December 29, 1970,

states “An Act: To assure safe and healthful working conditions for working

men and women …”

Section 5 of the Act titled Duties goes on to state that the employer “shall

furnish to each of his employees employment and a place of employment which are

free from recognized hazards that are causing or are likely to cause death or

serious physical harm to his employees.” An electrical arc flash is a “recognized hazard” and must

be analyzed to determine the magnitude and to determine the proper personal

protective equipment (PPE) that must be used by employees who may be exposed to

the hazards. OSHA, on June 27, 1974, issued

1910.132, General Requirements, under Subpart I, Personal Protective Equipment. Section 1910.132(d)(1) requires “The employer shall assess the workplace to determine if

hazards are present, or are likely to be present, which necessitate the use of

personal protective equipment (PPE).” The

requirements for assessing the workplace to determine if hazards are present

(which includes the electrical hazards of shock and arc flash) has been a

requirement for 40 years.

The Occupational Safety and Health Administration

(OSHA) issued the Final Rule of the Electrical Safety-Related Work Practices

regulation on August 6, 1990. OSHA 1910.335 Safeguards

for personnel protection,

paragraph (a) Use of protective equipment. (1) Personal protective equipment. (i) requires “Employees working in areas

where there are potential electrical hazards shall be provided with, and shall

use, electrical protective equipment that is appropriate for the specific parts

of the body to be protected and for the work to be performed.” Although the intent of this paragraph is to

require PPE for protection against the shock hazard, the arc flash hazard can

also be included because it is a potential electrical hazard. To further

illustrate this, 1910.335(a)(v) states: “Employees shall wear protective

equipment for the eyes or face wherever there is danger of injury to the eyes

or face from electric arcs or flashes or from flying objects resulting from

electrical explosion.” In

addition paragraph (a)(2)(ii) states that “Protective shields, protective

barriers, or insulating materials shall be used to protect each employee from

shock, burns, or other electrically related injuries while that employee is

working near exposed energized parts which might be accidentally contacted or

where dangerous electric heating or arcing might occur.”

The initial OSHA generic requirements, as noted above,

for performing the hazard analysis and the requirements to protect employees

where electric arcing might occur has been around for quite a few years. The

formal requirement for performing the arc flash hazard analysis were first

issued by the National Fire Protection Association (NFPA) and were published in

the 1995 edition of NFPA 70E Electrical Safety Requirements for Employee

Workplaces, as specified in Section 2-3.3.3

Flash Hazard Analysis of that

edition. This edition also provided an appendix that included additional

information for calculating the flash protection boundary in PART II,

Appendix B, Sample Calculation of Flash Protection Boundary.

The 2000 edition of NFPA 70E, Section 2-1.3.3 Flash

Hazard Analysis, expanded by including

the requirements for employees to wear Flame Resistant (FR) Clothing and

Personal Protective Equipment (PPE).

The 2000 edition also added, under Section 3-3.9 Selection of Personal

Protective Equipment, the hazard/risk

category Table 3-3.9.1 Hazard Risk Category Classifications, which was based on “assumed normal short circuit

current capacities and fault clearing times for various tasks conducted on

low-voltage (600 volts and below) equipment.” Table 3-3.9.2 Protective Clothing and Personal Protective

Equipment (PPE) Matrix was also added

to identify specific protective clothing and equipment for the various hazard/risk

category classifications. An additional table was also added to provide a

clothing description for each of the hazard risk categories in Table 3-3.9.3 Protective

Clothing Characteristics. Included in

this table was the Hazard Risk Category, Clothing Description, Total Weight

oz/yd2, and the Minimum Arc Thermal Performance Exposure Value

(ATPV) or Breakopen Threshold Energy (EBT) Rating of PPE cal/cm2.

Section 3-3.9.5 then outlined the arc flash protective equipment requirements.

Appendix B was expanded to include Section B-5 Calculation of Incident

Energy Exposure for a Flash Hazard Analysis that provides equations used to predict the incident energy produced

by a three-phase arc on systems rated 600 volts and below.

Since

the 2002 edition of the National Electrical Code (NEC) there has been the

requirement, in Section 110.16 Arc-Flash Hazard Warning (see Figure 1) to install arc flash warning labels on

industrial control panels, motor control centers, panelboards, and switchboards

that are likely to require examination, adjustment, servicing, or maintenance

while energized. These warning labels are required to be installed in a manner

that will be clearly visible to the qualified person who is performing electrical

work on the equipment. Informational Note No. 1 to 110.16 refers to NFPA 70E

for assistance in determining the potential exposure, safe work practices, and

PPE requirements.

Figure 1

Arc Flash Warning Label

Also

in 2002, the Institute of Electrical and Electronics Engineers (IEEE) issued

IEEE Std 1584 IEEE Guide for Performing Arc-Flash Hazard Calculations. This guide was developed to provide techniques for

determining the arc flash hazard distance and the incident energy to which

employees could be exposed during their work with electrical equipment. Methods

for calculating the incident energy of an arc flash and for establishing the

arc flash boundary in three-phase ac systems are addressed. It also covers the

analysis process from field data collection to final calculated results, provides

the equations necessary to determine incident energy and the arc flash boundary,

and discusses software solutions that can also be used. Also provided is an empirically

derived model for enclosed equipment and open power lines for voltages ranging from

208 V to 15 kV, along with a theoretically derived model applicable for any

voltage. Currently IEEE Std 1584 only addresses three-phase; single-phase ac

systems and dc systems are not included.

The 2004 edition of NFPA 70E was reorganized and

therefore the references to the arc flash hazard analysis changed. Section

110.8(B) Working On or Near Exposed Electrical Conductors or Circuit Parts

that Are or Might Become Energized

(1) Electrical Hazard Analysis (b)

Flash Hazard Analysis provided the direction to

perform the arc flash hazard analysis and referred to Section 130.3 for the

specific requirements for conducting the arc flash hazard analysis. Annex D, Sample

Calculation of Flash Protection Boundary

continued to provide additional information for performing the arc flash hazard

analysis. Annex D also included calculation methods from IEEE Std 1584-2002.

In

addition to the OSHA and NFPA 70E requirements the 2007 edition of ANSI/IEEE

C2, National Electrical Safety Code

(NESC) Section 41 Supply and communications systems – Rules for

Employers, 410 General

requirements, paragraph A.3. requires

the employer to perform an assessment to determine employee exposure to

electric arcs and estimate the incident energy to determine the appropriate

clothing and PPE to be worn by employees. This further emphasized the need to

perform the arc flash hazard analysis.

NFPA

70E-2009 made minor revisions to the requirements which included changing

“Flash Hazard Analysis” to “Arc Flash Hazard Analysis”. One significant

revision was the inclusion of the requirements to consider the design of the

overcurrent protective device and its opening time as well as the condition of

maintenance as part of the arc flash hazard analysis. Paragraph 130.3(C)

Equipment Labeling was added to emphasize the NEC 110.16 requirement to install

a warning label on electrical equipment that specified the available incident

energy or the required level of PPE. Annex D was revised to “Incident Energy

and Flash Protection Boundary Calculation Methods” in order to further emphasis calculation methods for

determining the incident energy and the arc flash boundary.

The 2012 edition of NFPA 70E contains several major

revisions to the arc flash hazard analysis requirements. Section 110.8 in

previous editions was eliminated and the requirements moved to other sections.

As an example 110.8(B) was revised and moved to a new Section 130.3(B) and the

specific requirements for the arc flash hazard analysis were moved to Section

130.5. Section 130.5(C) Equipment Labeling was expanded to identify the types of equipment requiring labeling as

well as specific types of information that is required on the label. One very

important requirement was added to the equipment labeling and is stated in the

last sentence of 130.5(C), which states “The method of calculating and data

to support the information for the label shall be documented.” Whether the incident energy of a potential arc

flash is calculated using Annex D or engineering software programs, or whether

it is determined through use of Table 130.7(C)(15)(a) Hazard/Risk Category

Classifications and Use of Rubber Insulating Gloves and Insulated and

Insulating Hand Tools-Alternating Current Equipment (Formerly Table 130.7(C)(9), the calculation methods

and the data used to determine the information of the warning label must be

documented. This information would include the available short circuit current,

the clearing time of the overcurrent protective device, the working distance of

the employee, and the arc gap. The Hazard/Risk Category Tables cannot be used

at “face value” without verifying the parameters that are noted in each task

group.

Another

significant revision that occurred in the 2012 edition is the inclusion of

direct current (DC) arc flash calculation methods found in Annex D, Section D.8

Direct-Current Incident Energy Calculations and the DC hazard/risk categories found in Table

130.7(C)(15)(b) Hazard/Risk Category Classifications and Use of Rubber

Insulating Gloves and Insulated and Insulating Hand Tools — Direct

Current Equipment.

OSHA issued the Final Rule Federal Register revision

of 29 CFR 1910.269 Electric Power Generation, Transmission, and Distribution, and 1926 Subpart V Electric Power Transmission

and Distribution. One of the

significant revisions is the requirement for the employer to estimate incident

energy of potential arc flash incidents. The following OSHA quotes are provided

for information:

1910.269(l)(8) Protection from flames

and electric arcs.

(i) The employer shall assess the

workplace to identify employees exposed to hazards from flames or from electric

arcs.

(ii) For each employee exposed to hazards

from electric arcs, the employer shall make a reasonable estimate of the

incident heat energy to which the employee would be exposed.

1926.960(g) Protection from flames and electric

arcs.

(1) Hazard assessment. The employer shall assess the workplace to identify

employees exposed to hazards from flames or from electric arcs.

(2) Estimate of available heat energy. For each employee exposed to hazards from electric

arcs, the employer shall make a reasonable estimate of the incident heat energy

to which the employee would be exposed.

The requirements to perform

the arc flash hazard analysis, which is used to determine the incident energy

of a potential arc flash, establish the arc flash boundary, and determine the

required clothing and PPE has been a requirement for many years. These

requirements continue to increase through revisions to NFPA 70E, the NESC, and

OSHA.

Maintenance of overcurrent protective devices

One

of the key components in performing the arc flash hazard analysis is the

clearing time of the protective devices, primarily circuit breakers, protective

relays, and fuses. Fuses, although they are overcurrent protective devices, do

not have operating mechanisms that would require periodic maintenance;

therefore, they will not be addressed. The primary focus is the maintenance

issues associated with circuit breakers and electro-mechanical protective

relays. These devices have mechanical components or operating mechanisms that

require periodic maintenance, testing, cleaning, adjustments, and lubrication

in order to function properly. According to the manufacturer’s specifications

these devices are required to operate and open the device contacts is a

specified amount of time, generally expressed in cycles or fractions of a

second. Where proper maintenance, testing, adjustments, and lubrication are not

performed or are performed improperly, extended clearing times could occur

creating an unintentional time delay that will effect the results of arc flash

hazard or incident energy analysis.

All

maintenance and testing of the electrical protective devices must be

accomplished in accordance with the manufacturer’s instructions. In the

absence of the manufacturer’s instructions, industry consensus standards such

as the NFPA 70B, Recommended Practice for Electrical Equipment Maintenance, and InterNational Electrical Testing Association

(NETA) ANSI/NETA MTS Standard for Maintenance Testing Specifications for

Electrical Power Distribution Equipment and Systems, should be used for guidance on maintenance

frequency, methods, and tests that should be performed on overcurrent

protective devices.

Several

issues concerning proper maintenance and testing of these overcurrent protective

devices, according to the manufacturer’s instructions, will be addressed. Also

addressed will is how protective device maintenance relates to the electrical

arc flash hazard.

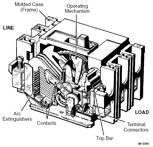

Molded-Case

Circuit Breakers -

Generally, maintenance on molded-case circuit breakers is limited to proper

mechanical mounting, electrical connections, and periodic manual operation.

Most lighting, appliance, and power panel circuit breakers have riveted frames

and are not designed to be opened for internal inspection or maintenance. All

other molded-case circuit breakers that are UL approved are factory-sealed to

prevent access to the calibrated elements. An unbroken seal indicates that the

mechanism has not been tampered with and that it should function as specified

by UL. A broken seal generally voids the UL listing and the manufacturers’

warranty of the device. In this case, the integrity of the device would be

questionable. The only exception to this would be a seal being broken by a

manufacturer’s authorized facility.

Molded-case

circuit breakers receive extensive testing and calibration at the

manufacturers’ plants. These tests are performed in accordance with UL 489, Standard

for Safety, Molded-Case Circuit Breakers, Molded-Case Switches and Circuit

Breaker Enclosures. Molded-case

circuit breakers, other than the riveted frame types, are permitted to be

reconditioned and returned to the manufacturer’s original condition. In order to conform to the manufacturer’s original

design, circuit breakers must be reconditioned according to recognized standards. The Professional Electrical Apparatus

Recyclers League (PEARL) companies follow rigid standards to recondition

low-voltage industrial and commercial molded-case circuit breakers. It is

highly recommended that only authorized professionals recondition molded-case

circuit breakers.

Circuit breakers installed in a system are often

forgotten. There is often the attitude that “the lights are on or the machines

are running, so everything is working fine”. The circuit breakers are not

“working fine” it is closed and working properly would not be indicated until

the circuit breaker is required to trip due to an overload or short circuit, or

simply opening the circuit breaker to deenergize the circuit. Even though the circuit

breakers have been sitting in place supplying power to a circuit for years,

there are several things that can go wrong. The circuit breaker can fail to

open due to a burned out trip coil or because the mechanism is frozen due to

dirt, dried lubricant, or corrosion. The overcurrent device can fail due to

inactivity or a burned out electronic component. Many problems can occur when

proper maintenance, inspections, cleaning, and exercising of the circuit

breaker are not performed and the breaker fails to open under fault conditions.

This combination of events can result in fires, damage to equipment or injuries

to personnel.

All too often a circuit breaker fails because the

minimum maintenance (as specified by the manufacturer) was not performed or was

performed improperly. Small things like failing to properly clean and/or

lubricate a circuit breaker can lead to operational failure or complete

destruction due to overheating of the internal components. Common sense, as

well as manufacturers’ literature, must be used when maintaining circuit

breakers. Many manufacturers, as well as NFPA 70B, recommend that if a

molded-case circuit breaker has not been operated, opened or closed, either

manually or by automatic means, within as little as six months time, it should

be removed from service and manually exercised several times. This manual

exercise helps to keep the contacts clean due to their wiping action and

ensures that the operating mechanism moves freely. This exercise however does

not operate the mechanical linkages in the tripping mechanism (Figure 2). The

only way to properly exercise the entire breaker operating and tripping

mechanisms is to remove the breaker from service and test the overcurrent and

short-circuit tripping capabilities. A stiff or sticky mechanism can cause an

unintentional time delay in its operation under fault conditions. This could

dramatically increase the arc flash incident energy level to a value in excess

of the rating of personal protective equipment.

Figure 2

Principle Components of a

Molded-Case Circuit Breaker

Another consideration is addressed by OSHA in 29 CFR

1910.334(b)(2) which states:

“Reclosing circuits after protective device

operation. After a circuit is

deenergized by a circuit protective device, the circuit may NOT be manually

reenergized until it has been determined that the equipment and circuit can be

safely reenergized. The repetitive manual reclosing of circuit breakers or

reenergizing circuits through replaced fuses is prohibited.

NOTE: When it can be determined from the design of the circuit and the

overcurrent devices involved that the automatic operation of a device was

caused by an overload rather than a fault condition, no examination of the

circuit or connected equipment is needed before the circuit is reenergized.”

The safety of the employee manually operating the

circuit breaker is at risk if the short circuit condition still exists when

reclosing the breaker. OSHA no longer allows the past practice of resetting a

circuit breaker one, two, or three times before investigating the cause of the

trip. This previous practice has caused numerous burn injuries that resulted

from the explosion of electrical equipment. Before

resetting a circuit breaker, it, along with the circuit and equipment, must be

tested and inspected by a qualified person to ensure a short circuit condition

does not exist and that it is safe to reset. Any time a circuit breaker has

operated and the reason is unknown, the breaker must be inspected and tested.

Melted arc chutes or interrupters may not extinguish the arc when the breaker

opens under fault current conditions. If the breaker cannot properly interrupt

a second fault, it may fail and may destroy its enclosure and create a hazard

for anyone working near the equipment.

To

further emphasize this point the following quote from the National Equipment

Manufacturer’s Association (NEMA) is provided: (Vince A. Baclawski, Technical

Director, Power Distribution Products, NEMA; published in EC&M magazine,

pp. 10, January 1995)

“After

a high level fault has occurred in equipment that is properly rated and

installed, it is not always clear to investigating electricians what damage has

occurred inside encased equipment. The circuit breaker may well appear

virtually clean while its internal condition is unknown. For such situations,

the NEMA AB4 ‘Guidelines for Inspection and Preventive Maintenance of MCCBs

Used in Commercial and Industrial Applications’ may be of help. Circuit

breakers unsuitable for continued service may be identified by simple

inspection under these guidelines. Testing outlined in the document is another

and more definite step that will help to identify circuit breakers that are not

suitable for continued service.

After the occurrence of a short circuit, it is

important that the cause be investigated and repaired and that the condition of

the installed equipment be investigated. A circuit breaker may require

replacement just as any other switching device, wiring or electrical equipment

in the circuit that has been exposed to a short circuit. Questionable circuit

breakers must be replaced for continued, dependable circuit protection.”

The

condition of the circuit breaker must be known to ensure that it functions

properly and safely before it is put it back into service.

Low-Voltage

Power Circuit Breakers - Low-voltage power circuit breakers are

manufactured under a high degree of quality control, of the best materials

available, and with a high degree of tooling for operational accuracy.

Manufacturer’s tests show these circuit breakers to have durability beyond the

minimum standards requirements. All of these factors give these circuit

breakers a very high reliability rating. However, because of the varying

application conditions and the dependence placed upon them for protection of

electrical systems and equipment, as well as the assurance of service

continuity, inspections and maintenance checks must be made on a regular basis.

Several studies, including IEEE, have shown that low-voltage power circuit

breakers, which were not maintained within a given period of time, have a high

failure rate.

Maintenance

of these breakers will generally consist of keeping them clean and properly

lubricated. The frequency of maintenance will depend to some extent on the

cleanliness of the surrounding area. If there were very much dust, lint,

moisture, or other foreign matter present then more frequent maintenance would

be required.

Manufacturers

of low-voltage power circuit breakers recommend a general inspection, cleaning,

maintenance, testing, adjustments, and lubrication after a specified number of

operations or at least once per year, whichever comes first. Some manufacturers

also recommend this same inspection and maintenance be performed after the

first six months of service regardless of the number of operations. If the

breaker remains open or closed for a long period of time, it is generally recommended

that arrangements be made to open and close the breaker several times in

succession, preferably not under load conditions. Environmental conditions play

a major role in the scheduling of inspections and maintenance. If the initial

inspection indicates that maintenance is not required at that time, the period

may be extended to a more economical point. However, more frequent inspections

and maintenance may be required if severe load conditions exist or if an

inspection reveals heavy accumulations of dirt, moisture, or other foreign

matter that might cause mechanical, insulation, or electrical failure.

Mechanical failure would include an unintentional time delay in the circuit

breakers tripping operation due to dry, dirty or corroded pivot points or by

hardened or sticky lubricant in the moving parts of the operating mechanism.

The manufacturer’s instructions must be followed in order to minimize the risk

of any unintentional time delay.

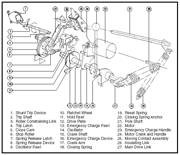

Figure

3 provides an illustration of the numerous points where lubrication would be

required and where dirt, moisture, corrosion or other foreign matter could

accumulate causing a time delay in, or complete failure of, the circuit breaker

operation.

Figure 3

Power-Operated Mechanism of a

Cutler/Hammer “DS” Circuit Breaker

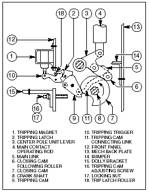

Medium-Voltage

Power Circuit Breakers - Most of the

inspection and maintenance requirements for low-voltage power circuit breakers

also apply to medium-voltage power circuit breakers. Manufacturers recommend

that these breakers be removed from service and inspected at least once per

year. They also state that the number and severity of interruptions may

indicate the need for more frequent inspections and maintenance. Always follow

the manufacturer’s instructions because every breaker is different and the

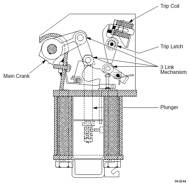

manufacturer knows what is best for their circuit breakers. Figures 4 and 5

illustrate two types of operating mechanisms for medium-voltage power circuit

breakers. These mechanisms are typical of the types used for air, vacuum, oil,

and SF6 circuit breakers. As can be seen in these figures, there

are many points that would require cleaning and lubrication in order for them to

function properly.

Figure 4

Operating Mechanism

Air Circuit Breaker

Figure 5

Solenoid-Operated

Mechanism

Arc Flash

Hazard Analysis - As noted at the beginning of this

article OSHA, the NESC, and NFPA 70E require an arc flash hazard or incident

energy analysis be performed before anyone approaches exposed energized electrical

conductors or circuit parts that have not been placed in an electrically safe

work condition. In addition, NFPA 70E requires an arc flash boundary to be

established. All calculations for determining the incident energy of an arc

flash and for establishing an arc flash boundary require the arc clearing time.

This clearing time is derived from the engineering coordination study, which is

based on what the overcurrent protective devices are supposed to do.

Maintenance

is a very critical part of the arc flash hazard issue. The information provided

here clearly indicates the need for a preventive maintenance program on these

circuit protective devices. Evidence has proven that inadequate maintenance

can cause unintentional time delays in the clearing of a short circuit

condition. If, for example, a low-voltage power circuit breaker had not been

operated or maintained for several years and the lubrication had become sticky

or hardened, the circuit breaker could take several additional cycles, seconds,

minutes, or longer to clear a fault condition. The following is a specific

example:

If an arc flash hazard analysis is

performed, based on what the system is supposed to do, let’s say a 5 cycle

clearing time, and there is an unintentional time delay, due to a sticky

mechanism, and the breaker clears in 30 cycles, the worker could be seriously

injured or killed because he/she was under protected.

If the calculation is performed for a

20,000-amp fault, 480 volts, 3-inch arc gap, and the worker is 18 inches from

the arc, with a 5 cycle clearing time for a 3-phase arc in an enclosure; the

results would be approximately 3.5 cal/cm2, which would require arc-rated

clothing and PPE, based on that level of incident energy. The following example

uses the NFPA 70E Annex D equation for a 5 cycle clearing time:

EMB = maximum 20 in. cubic box incident energy, cal/cm2

DB = distance from arc electrodes, inches (for distances

18 in. and greater)

tA = arc duration, seconds

F = short circuit current, kA (for the range of 16 kA to

50 kA)

(1) DA = 18 in.

(2) tA = 0.083 second (5 cycles)

(3) F = 20kA

EMB = 1038.7DB-1.4738tA[0.0093F2-0.3453F+5.9675]

=

1038x0.0141x0.083[0.0093x400-0.3453x20+5.9675]

=

1.4636x[2.7815]

=

3.5 cal/cm2

NFPA 70E, OSHA, and the NESC requires arc-rated

clothing and other PPE to be selected based on this incident energy level

exposure. Therefore the arc-rated clothing and PPE must have an arc rating of at

least 3.5 cal/cm2.

If the clearing time is increased to 30 cycles due to

a sticky mechanism then the results are approximately 20.4 cal/cm2,

which would require arc-rated clothing and PPE based on that level of energy. The

following example uses the NFPA 70E Annex D equation for a 30 cycle clearing

time:

EMB = maximum 20 in. cubic box incident energy, cal/cm2

DB = distance from arc electrodes, inches (for distances

18 in. and greater)

tA = arc duration, seconds

F = short circuit current, kA (for the range of 16 kA to

50 kA)

(1) DA = 18 in.

(2) tA = 0.5 second (30 cycles)

(3) F = 20kA

EMB = 1038.7DB-1.4738tA[0.0093F2-0.3453F+5.9675]

=

1038x0.0141x0.5[0.0093x400-0.3453x20+5.9675]

=

7.3179x[2.7815]

=

20.4 cal/cm2

NFPA 70E, OSHA, and the NESC requires arc-rated

clothing and other PPE to be selected based on this incident energy level

exposure. Therefore the arc-rated clothing and PPE must have an arc rating of

at least 20.4 cal/cm2.

If

the worker is protected based on what the system is supposed to do (0.083

second or 5 cycles – 3.5 cal/cm2) and an unintentional time

delay occurs (0.5 second or 30 cycles – 20.4 cal/cm2), the

worker could be seriously injured or killed because he/she would be under

protected.

As

can be seen, maintenance is extremely important to an electrical safety

program. Maintenance must be performed according to the manufacturer’s

instructions in order to minimize the risk of having an unintentional time

delay in the operation of the overcurrent protective devices.

Summary

With

the proper mixture of training, manufacturers’ literature, and spare parts,

proper maintenance can be performed and power systems kept in a safe, reliable

condition. Circuit breakers, if installed within their ratings and properly

maintained, should operate trouble-free for many years. However, if operated

outside of their ratings or without proper maintenance, catastrophic failure of

the power system, circuit breaker, or switchgear can occur causing not only the

destruction of the equipment but serious injury or even death of employees

working in the area.