Ten Questions to Mature Executive Safety Thinking

Cultures of today are a result of practices of the past.

All progress begins by thinking differently. Today's current views regarding safety excellence should be at least partially obsolete in 10 years: how safety excellence is defined and achieved, what the goals should be, who is responsible for what, and how long it will take in time and resources. What are your executive leaders' perspectives on this? How well aligned are they?

If the executive staff isn't aligned and there is no clear and understood strategy for achieving safety excellence, can you be surprised you have so many different cultures throughout the enterprise? Much of our work focuses on maturing and aligning the thinking and subsequent strategy and execution within an organization. This often begins with helping evolve current paradigms with senior leaders, who set the tone and direction not only for the culture, but the overall business trajectory.

Consider W. Edwards Deming's warning: "Your system is perfectly designed to give you the results you're getting." To operationalize that, employee behaviors are a byproduct of the systems and culture they work within, and that of their bosses all the way up the organizational hierarchy. If the leaders aren't leading advancement thinking within, don't expect the followers to follow. Cultures of today are a result of practices of the past.

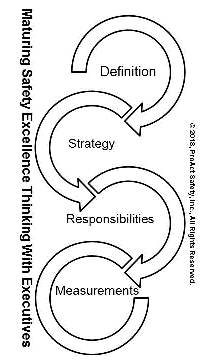

When maturing thinking, it is helpful to first gather a baseline of current thoughts around four key areas: how safety excellence is defined, the strategy to achieve it, who is responsible for what, and how data is leveraged and progress measured and achieved.

Below are 10 questions/statements to ask to gain insight into the current perspectives. It is recommended that answers are anonymous to allow for a more truthful perspective. Results should be shared with the respondents, allowing leaders to see how their peers replied. These outcomes alone will be a great catalyst for deeper conversations.

1. How do you define safety excellence?

2. As an executive, what common things would you see or hear when visiting a location that explains how safety excellence was achieved there?

3. When great safety performance is recognized, how do you confirm, or what data supports the results were achieved due to doing the right things rather than luck or temporary improvement?

4. What does data tell you to focus on to improve both safety performance and culture?

5. What do you see as the biggest challenge to further improve both safety performance and culture?

6. Describe your current multi-year strategy for achieving and sustaining excellence in safety performance and culture.

7. How does the current safety strategy support and enable the current business strategy, and are there areas where the safety strategy conflicts with or hinders the business strategy?

8. What elements of the safety strategy should be owned by the safety function versus operations and line leadership?

9. What do you see as the priorities for your safety executive (what should they be spending their time on)?

10. What do you see as the most important safety roles and responsibilities for someone in your position?

With the answers to these questions, not only will you gain an understanding of where the current thinking is, you will also know where to focus your efforts to help mature the thinking and, subsequently, align the safety efforts to strategically improve safety performance and culture. While there are many questions available to gauge the point of view of executive leaders, start with these. With the answers you receive, you will understand why.

For a template of these questions to use this in your organization, contact the author and reference Safety Executive Safety Questions. He can be reached at 936-273-8700 or [email protected].

This article originally appeared in the June 2018 issue of Occupational Health & Safety.