Page 4 of 4

Ear Plug Selection and Fitting Best Practices

Despite more than 30 years of regulatory advances and ever-increasing awareness of the danger, noise-induced hearing loss (NIHL) continues to be one of the leading preventable occupational injuries in the workplace. Yet many safety managers falsely assume that proper use of hearing protection is fairly intuitive, as easy as just purchasing "one size fits all" ear plugs and distributing to noise-exposed workers. In this discussion, Brad Witt, director of hearing conservation at Honeywell, identifies the critical steps to ensure hearing protection is properly selected, fitted, and worn to stop noise-induced hearing loss.

Q: Let's start at the beginning: selecting the proper ear plug. How can safety managers determine which ear plugs are the best fit for their workers?

A: Imagine sending a friend to the store to purchase shoes for you, with the following instructions: "Any size, any shape, any style … doesn't really matter!" Many people select ear plugs in the same carefree manner. The prevailing assumption is that "anything in my ear will protect my hearing—it doesn't really matter." In reality, ear canals come in different sizes and shapes, affecting both fit and protection levels, as well as comfort. A work site that offers only one size or style of ear plug sabotages its own hearing conservation efforts.

Q: Why is variety so important?

A: In one study of typical ear canal sizes across gender and populations, results showed that females typically have ear canals approximately 20 percent smaller than males, and those of Asians and Africans have significantly smaller ear canals than Caucasians as a population.1 In addition to these general differences according to gender and ethnicity, there are also significant individual differences in ear canal size.

One of the real benefits of offering a variety of hearing protection sizes and styles is the fact that it can generally be accomplished with little or no increase in cost. Whether a work site offers 1,000 ear plugs of one style or 250 ear plugs of four different styles, the cost would be quite similar. By offering workers more variety in ear plug selection, companies will provide a better fit for more ears and protect significantly more of their workers.

Fit-testing of hearing protection now allows a worker to try various hearing protectors to determine which type is most suitable. Often, the worker's first choice of ear plugs is not the best. But with dozens of different styles available, it can be difficult to decide which ear plug would be a better choice for a given worker.

Q: And if at first you don't succeed? What should safety advisors try next when a worker achieves poor results with the ear plug first selection?

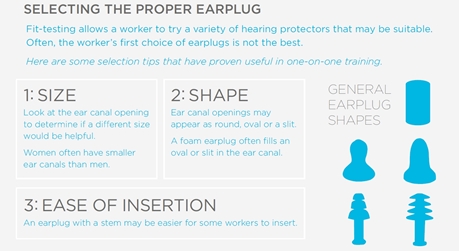

A: This is not an uncommon situation. Based on our experience with one-on-one training, there are three critical considerations when optimizing the fit of an ear plug:

1. Size. Like a cork in a bottle, an ear plug that is too large or too small will never achieve an acoustic seal. Look at the ear canal opening to determine whether a different size would be helpful. Yes, ear plugs do come in different sizes, and there is no such thing as a "one-size-fits-all" ear plug. The results from thousands of fit tests we've conducted at work sites show that a minimum of four ear plug sizes and styles are required to accommodate the needs of a workforce. These include:

1. Size. Like a cork in a bottle, an ear plug that is too large or too small will never achieve an acoustic seal. Look at the ear canal opening to determine whether a different size would be helpful. Yes, ear plugs do come in different sizes, and there is no such thing as a "one-size-fits-all" ear plug. The results from thousands of fit tests we've conducted at work sites show that a minimum of four ear plug sizes and styles are required to accommodate the needs of a workforce. These include:

- Large foam ear plug

- Large reusable ear plug

- Smaller foam ear plug

- Smaller reusable ear plug

2. Shape. In addition to different diameters, ear canals come in different shapes. While many ear canals are round (well fitted with a pre-molded ear plug), many have a distinct oval shape (or even a slit opening) best fitted with an expandable foam ear plug.

3. Ease of Insertion. Some workers have difficulty rolling or inserting foam ear plugs due to restricted dexterity or arthritis. For these workers, a no-roll foam or reusable ear plug is the preferred choice. Also, push-in ear plugs with a stem may be easier for some workers to insert, providing a trustworthy reliable fit. In ear plug fitting, depth of insertion is so critical to achieve adequate protection levels; an eighth of an inch deeper can double the protection in many cases. So our goal is to offer a variety of styles that will allow every worker to achieve adequate protection.

That said, in addition to size, shape, and ease of insertion, there are many other options available in ear plugs that factor into proper selection:

- Corded or uncorded

- Single-use or reusable

- Detectable ear plugs, as used in the foodservice industry

- Uniform attenuation across frequencies affecting speech clarity

Q: There is often some misunderstanding as to how the Noise Reduction Rating plays into the selection process, correct?

A: There certainly is. It may be surprising to some, but the published rating of an ear plug—the Noise Reduction Rating, or NRR—is simply not a good selection factor. In fact, it can be quite deceptive in selecting proper protection. The NRR is a laboratory-based estimate of the amount of protection potentially achieved when the ear plug is properly sized and properly fitted. Based upon the testing protocol behind the NRR, large foam ear plugs have quite an advantage in generating higher ratings. So if a safety manager were to select ear plugs based solely on a high NRR, they would unwisely choose large foam ear plugs for their entire workforce. The safety manager would find many workers would never be able to achieve a good fit with that large ear plug and hear comments like, "It keeps falling out of my ears." It would offer little protection from hazardous noise.

Q: Do workers often wear ear plugs that don't really offer much protection, due to poor selection or fit?

A: One of the major benefits of fit-testing hearing protectors is to identify those workers who have a poor fit. In some facilities, we have found more than half the noise-exposed workers "fail" to achieve even 50 percent of the protection levels on the package, even though they are part of an ongoing hearing conservation program that includes training and audiometric testing. This "failure," though, is actually the ideal opportunity to provide critical one-on-one training in proper fitting of the ear plug.

Q: Based on your experience, are there specific steps that you would recommend?

Q: Based on your experience, are there specific steps that you would recommend?

A: Here are three proven best practices that are easy to teach for proper ear plug fit:

1. Roll

- For roll-down foam ear plugs, start rolling the foam gently to avoid creases. Then roll as hard as you can to make the cylinder as small as possible.

- Rolling the ear plug into a tight cylinder makes it easier to fit around the bends in the ear canal.

- After rolling, move quickly to the next step so that the ear plug doesn’t expand before insertion.

2. Pull

- Reach over the head to pull OUT (or for some people, pull UP or BACK) on the ear flap, called the pinna. Firmly pulling the ear OUT helps spread open the ear canal for a more effective fit.

- Observe the worker's ear: Which direction opens the ear canal the most? Give feedback to the worker about which pull direction is most effective. For many people, pulling OUT away from the head is most effective in spreading open the ear canal for a better ear plug fit.

3. Insert

- Insert the ear plug far enough so that it goes around bends in the ear canal. This often feels sensitive (not painful) or may trigger a cough reflex. This is normal.

- Let go of the pulled-back ear after the ear plug is fully inserted.

- For foam ear plugs, hold the ear plug in place for a few seconds while the foam expands to fill the ear canal.

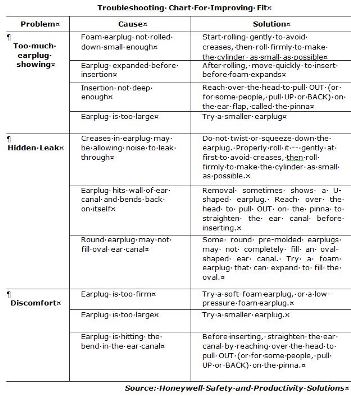

For further reference, we've developed a troubleshooting chart for improving fit.2 It describes the most common symptoms and solutions for fixing a bad fit, significantly improving the protection levels for noise-exposed workers.

Q: So there really is more to hearing protection than just passing out ear plugs?

A: Yes, but many companies find that by investing in proper selection, fit, and training, the benefits are manifold. Workers recognize what a good fit feels like and sounds like. They are more likely to wear hearing protectors properly off the job as well as on the job, and cross-training within the peer group increases. Rates of hearing shifts due to workplace noise decline, and indeed, the Hearing Conservation Program successfully stops noise-induced hearing loss.

References

1. Thomas, W., Wright, W., Casali, J. Ear Canal Measurement: Eargage™ versus ear impressions. Paper presented at the 19th Annual NHCA Conference, January 1994. Appears in Spectrum, 11(1), 34-35.

2. An interactive version of the Fix-A-Fit guide from Honeywell Industrial Safety can be downloaded from http://www.howardleight.com/hearing-protection/FIX-A-FIT

This article originally appeared in the March 2017 issue of Occupational Health & Safety.

About the Author

Brad Witt, MA, CCC-A, is the Director of Hearing Conservation for Honeywell Safety Products, the manufacturer of Howard Leight® hearing protection products. He holds a B.S. in Communication Disorders from Brigham Young University, and an M.A. in Audiology from Northwestern University. For 14 years, he managed a hearing conservation practice in California, providing OSHA-standard services at 175 locations. He has served as president of the National Hearing Conservation Association (NHCA) and has presented more than 250 hearing conservation seminars on behalf of Howard Leight during the past eight years in 18 countries. Contact him by e-mail at brad.witt@honeywell.com.