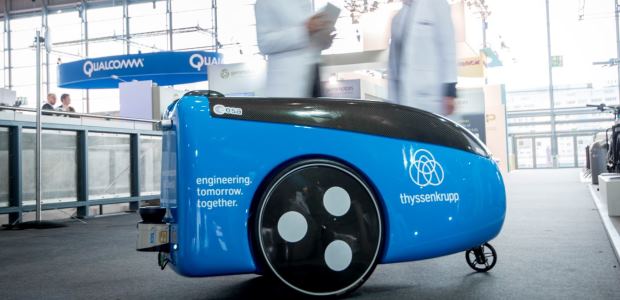

Thyssenkrupp Elevator Testing Delivery Robots

In a pilot program, robots will transport spare parts and other material to elevator maintenance job sites. The company says cloud-based driverless systems could form complete supply and logistics networks.

Working with software developer TeleRetail, thyssenkrupp Elevator has launched a pilot project in which delivery robots will transport spare parts and other material to elevator maintenance job sites. The company says cloud-based driverless systems could form complete supply and logistics networks, calling this a promising solution with enormous development potential.

TeleRetail is a Swiss company with U.S. operations headquartered in Sunnyvale, Calif.

Compact delivery robots will ensure that packages get to their destination by the quickest route possible, thyssenkrupp Elevator reported Sept. 14, adding that they could be an optimal logistics solution for elevator and escalator servicing because spare parts are needed quickly, and a technician either has to drive back to base in his service vehicle or have it delivered by a colleague. But with increased traffic clogging up city streets, the pressure on supply chains is increasing all the time.

"This is a challenge of urbanization that our service technicians are already experiencing today," said Ivo Siebers, senior vice president of global logistics at thyssenkrupp Elevator. "With driverless delivery robots, we could fill a gap and get spare parts from our warehouses to the job site faster, more flexibly, and with less impact on the environment."

The delivery robots in the pilot project are less than 3 feet wide, so they can travel on sidewalks and avoid road congestion. They can also reach inner-city areas where vehicular transport is limited and carry payloads weighing up to 187 pounds. Information on delivery status can be obtained quickly via an online logistics automation platform.

"With our platform we want to optimize logistics by saving time and costs and minimizing space requirements, energy consumption, and emissions," explained Torsten Scholl, CEO of TeleRetail Mobility Automation.