No Power? No Problem

Facilities develop plans to control most aspects of their operation. They control the hours of operation, the amount of time employees spend at work, and general operation costs. There is one thing that facilities have no control over: power outages. These can strike at any time, for any reason, such as storms or sudden accidents that have the potential to cripple your loading dock operations.

Dealing with power outages can drastically affect your operations due to injuries or even fatalities, especially if you don't have a Plan B in place. According to the U.S. Department of Energy, Americans lose about $150 billion every year due to power outages. Whether a power outage is caused by environmental factors or inadequate grids and networks, the average American loses more than 200 minutes of power each year.

Electrical and power outage-related hazards are nothing new to the world of occupational safety. In 2006, NIOSH reported that in its 10-year study from 1992 to 2002, 3,378 U.S. workers were killed and another 46,598 were injured in electrical incidents. While even a small percentage (2 percent) resulted from power outages, those numbers are still staggering.

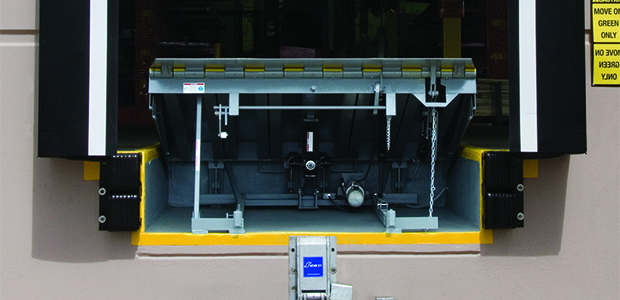

How can you prevent your facility from suffering major losses during power outages? Having backup generators can help, but they can be very expensive. At the very least, you should have a backup plan for power outages that can help you reduce injuries and downtime. A simple backup plan could be to install Power-Assisted Dock Levelers in your facility as a supplement to your regular dock operations. The PAL is designed to maintain an efficient operation, no matter the condition of your power. If there's a power failure during loading or unloading at the dock, the PAL has a manual activation device that lets workers secure the building or continue with loading and unloading.

They act as a hybrid leveler that provides you with flexibility and operational efficiency, more so than mechanical levelers, while also eliminating the extra costs associated with mechanicals due to the frequent adjustments those require. These levelers also remain active and engaged with a trailer during a power outage, reducing the potential for the leveler to become stuck or moving while a forklift is passing over it.

So what about your vehicle restraints if you experience a power loss but need to release trailers? Many powered vehicle restraints are available with an auxiliary power-down capability to allow speedy, safe release of trailers in the event of a power loss. These give facilities yet another means of staying safe and productive in the event of a power outage.

When it comes to dealing with circumstances out of your control in your facility, such as power outages, it's important to have your contingency plan so your productivity doesn't go down with the power.

Michael Brittingham is manager of Marketing Communications at Serco Entrematic.

Posted on Jan 28, 2014