Combining Safety Job Hazard Analysis & Lean Six Sigma to Improve Machine Guarding

Similar to the Toyota Production System, we must all strive to eliminate waste (in our case, lost productivity from job hazard injuries) from our organizations.

- By Joseph P. Gasparino Jr.

- Dec 01, 2016

A common tool that we can all relate to is the pedestal/bench grinder. It is used in almost every setting, from multinational corporations, distribution, government, to small private companies. If organizations are tracking their incidents and injuries, I am sure almost all can confirm the pedestal/bench grinder has a high injury rate. The frequent usage coupled with the risk is the reason why bench grinders remain in the top 10 OSHA cited violations. When you think about the risks, the grinding wheel diameter shrinking over time with usage is a ticking time bomb for injuries and fines. It is like driving a car without a gas gauge. It is not "if," it is "when" will you run out of gas. Now that a clearly defined universal problem is outlined, let's review the process on how to combine safety Job Hazard Analysis (JHA) with Lean Six Sigma (LSS) to come up with an Autonomation machine guarding solution.

So, what is a Job Hazard Analysis? Per the OSHA definition, a job hazard analysis is a technique that focuses on job tasks as a way to identify hazards before they occur. It focuses on the relationship between the worker, the task, the tools, and the work environment. Ideally, after you identify uncontrolled hazards, you will take steps to eliminate or reduce the hazards to an acceptable risk level. Furthermore, to eliminate or reduce the job's uncontrolled hazards, you must identify whether the task requires the use of personal protective equipment (PPE), administrative, and/or engineering controls. If you are Lean thinking, there should be flags here as PPE and administrative controls' success rates are both dependent upon human factors, whereas engineered controls can be nearly foolproof. So let's carry the output of the job hazard analysis and input the current state solutions into a Six Sigma PFMEA.

So, what is a Six Sigma PFMEA? A Process Failure Mode Effects Analysis is an analytical technique to identify potential failure modes and their associated causes/mechanisms, assign a risk priority number, and address ways to mitigate the potential failures through enhanced processes or increased detection controls. Furthermore, when finalizing the PFMEA process, we will then be able to apply another Six Sigma tool, a Pareto by risk priority number.

So, what is a Pareto? The Pareto principle was named after economist Vilfredo Pareto; it specifies an unequal relationship between process inputs and outputs. For our case, the principle would estimate that 80 percent of injuries comes from 20 percent of the tasks; this is also referred to as the "Pareto Rule" or the "80/20 Rule." The principle serves as a general reminder that the relationship between inputs and outputs is not balanced and allows the discovery of the true impact by task. For our bench grinder case study, the inputs are the process tasks and the outputs are the injuries. In theory, the Pareto analysis would say 20 percent of the pedestal/bench grinder processes account for 80 percent of the injuries. Now that we have identified the tasks that are the largest injury risk priority number, let’s apply Lean Autonomation for a foolproof solution and see how the Pareto rule applies.

So, what is Lean Autonomation? As many are aware, Toyota Motor Corp. has the famous Toyota Production System (TPS), or as the West calls it, Lean Manufacturing. The Toyota Production System has two main pillars, the famous Just-In-Time or JIT, and Jidoka or Autonomation. In my opinion, I would consider Autonomation, which is a feature of machine design to give intelligent automation with a human touch, the foundation of TPS. Before Toyota Motor Company and JIT, Toyoda Sakichi (founder of Toyota Motor Company) was a well-known master inventor of auto-activated weaving machines. His machines were known to "poka-yoke," or foolproof systems to prevent defective products. The process behind Autonomation or "giving the machine intelligence" was 1) the machine must detect the abnormality 2) it must STOP the operation 3) human touch must fix or correct the immediate failure condition 4) a team must investigate the root cause and install a countermeasure. Toyoda Sakichi believed that stopping the machine when there is trouble forces awareness on everyone. When the problem is clearly understood, only then is improvement possible. Production line stoppages for defects and safety are mandatory and the heart of TPS.

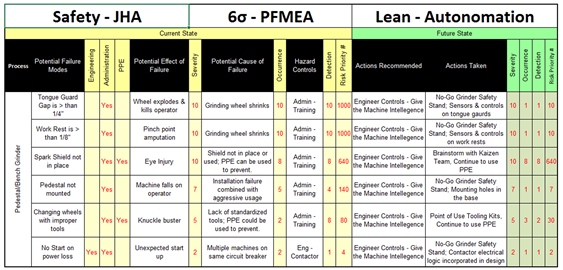

To recap the process, we will perform a safety JHA, then perform a Six Sigma PFMEA, followed by a Pareto sort by risk priority number. The Pareto sort will highlight the largest risk priority number factors and allow laser focus of Lean Autonomation thinking. So let’s apply this process to our common pedestal/bench grinder safety issue that plagues many organizations in many industries. We will then summarize the results and conclude with recommended next steps. The recommended next steps are to stimulate readers’ continuous improvement thinking.

Review of the process . . . JHA, PFMEA, PARETO, & AUTONOMATION

We have selected six tasks with a pedestal/bench grinder within this JHA example. As a lean thinker, there are a few ways to analyze the results. First, there are only two tasks that can be protected with PPE, eye injuries with safety glasses/faceshield and wearing gloves when changing the wheels. Both are dependent on human factors for results. The next three risks are the tongue guards, work rests, and the mounting of the pedestal/bench grinder. For all three, PPE will not prevent injuries, and with current-state designs, the only prevention is administration training, again, human factors dependent. The lone "no start on power loss" risk can be engineered out with a start/stop contactor, but this is not a standard option and must be specifically requested.

This simple tool has quite a large window of risk, from knuckle buster to eye injury, to hand injury, to wheel debris drastically injuring or even causing known deaths. By carrying these risks into the PFMEA analysis, we can then multiply the severity, occurrence, and current state detection to obtain the risk priority number. When you Pareto sort the PFMEA by risk priority number, you can apply additional Lean thinking analytics. Using the 80/20 rule, the tongue guards and work rests are 20 percent of the tasks but are accounting for 80 percent of the injury risks. Again, with the grinding wheel diameter shrinking based on the amount of usage, it causes inevitable risks. Coupled with the catastrophic injuries that are completely based on administrative training and human factors, the tongue guards and work rests are ideal candidates for Lean Autonomation. The others did not rank as high due to having PPE protection and the severity of risks being comparatively smaller. We can now transition to Lean Autonomous thinking with the tongue guards and work rests as the key focus for machine guarding improvements as discovered through the Pareto of the PFMEA Six Sigma tool.

To properly come up with an Autonomation countermeasure, let's focus on these two issues and find the root cause. To keep it simple, we can use the Six Sigma 5-whys tool to begin the process.

- WHY? Second shift operator got seven stitches on a pedestal/bench grinder yesterday.

- WHY? His finger was pulled into the grinder while performing a grinding task.

- WHY? The gap on the work rest exceeded the OSHA 1910.215 standard of >1/8”.

- WHY? This was his first time performing this operation and he didn’t remember his training from 10 months ago.

- WHY? The grinding wheel diameter shrinks over time with usage and is dependent on the operators to check for compliance and risk.

Root Cause: The grinding wheel shrinks over time with usage and is dependent upon human factors to be checked and adjusted to reduce injuries and OSHA fines risks.

Corrective Action: Engineer controls that will monitor and stop the grinder if the tongue guards are greater than 1/4" and the work rests are greater than 1/8".

Autonomation Design/Solution: With sensors on each tongue guard and work rest, they can monitor the distance from the guards to the wheel. Electronic controls can be coupled with a contactor, which will eliminate another safety risk. The controls, contactor, and power supply can be incorporated into a stand that is designed for mounting, eliminating yet another hazard. The controls will also have a fault light, signaling an issue and work stoppage to the operator. Now, human touch and work stoppage should trigger countermeasure thinking.

Next Steps

From a qualitative perspective, we have used this process to improve a multi-industry problem by reducing OSHA compliance risk and job hazard exposure of our employees. Quantitatively, we have reduced the original six identified tasks from a total current state risk priority number of 2,864 down to a future state of 699, a 75 percent reduction.

To a Lean continuous improvement thinker, this is just the beginning. Let's consider the following takeaways:

- How can we engineer the other 25 percent risk out of the process?

- What other tasks were missed in the JHA evaluation?

- Can this sensor technology be used on other machines within the facility?

- What other high-risk injury prone processes can the JHA/PFMEA/Autonomation process be applied to?

- How could we improve the JHA/PFMEA/Autonomation process?

Similar to the Toyota Production System, we must all strive to eliminate waste (in our case, lost productivity from job hazard injuries) from our organizations. Based on my experience, the safety culture directly correlates to business success. A great safety culture will bring robust quality, robust quality enhances delivery, enhanced delivery lowers costs. Lower costs win the game. Good luck on your safety continuous improvement journey!

This article originally appeared in the December 2016 issue of Occupational Health & Safety.