Six Tips to Improve Your Lockout/Tagout Program

A program that encourages communication can identify strengths and weaknesses much more efficiently than a program that remains static and unchanging after initial training.

- By Eric Prinzing

- Aug 01, 2016

Lockout/tagout compliance is a crucial safety requirement. Preventing the accidental start-up of energy during repair or maintenance ensures the safety of workers and helps to create a productive workplace.

The OSHA Lockout/Tagout Standard (1910.147) provides clear lockout safety requirements. Despite this, lockout/tagout (LOTO) continues to be found in OSHA's top 10 most frequently cited standards. It should be seen, then, as a serious and widespread concern. This article will provide six tips to help your company stay compliant.

1.Choose the Right Devices

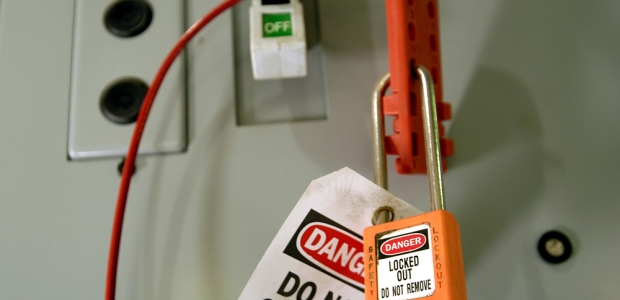

A lockout device is an extremely important component of a LOTO program. Industrial machines, circuit breakers, plugs, switches, push buttons, and valves are just some of the items that often require lockout devices. Since there are so many choices, choosing which device to purchase may seem overwhelming. There are two considerations that will help: necessity (knowing exactly what you need) and organization (using standardized devices and tools to help keep your devices organized).

First, determine exactly what you need. OSHA's guidelines are certainly helpful, but each workplace is unique. Create a list of all machines or electrical components that may need lockout devices. This will make buying the most appropriate device easier because most lockout devices are designed to meet a specific application.

Second, standardize and organize your lockout devices. Lockout Stations are one effective way to store and organize necessary devices. This has several benefits: Not only do stations store necessary devices, but also they save valuable space and promote efficient operations. If devices are organized in a station, workers know exactly where to find the devices that they need during maintenance or repair. Padlocks should also be standardized by size and color so that workers can easily identify function and ownership.

2. Thoroughly Document Procedures

Lockout procedures need to be formally documented. This will keep workers and management on the same page and help to eliminate any potential confusion. Documentation also provides workers with a valuable training resource. Formal documentation is required by OSHA but, given the differences in workplaces and machines, not every procedure will be the same. It is especially important, then, to make sure the procedures are as effective as possible.

Procedures should thoroughly detail the steps needed to shut down and isolate hazardous energy. The procedures also should describe how to safely place and remove all relevant lockout/tagout devices.

In order to make the lockout process as easy to follow as possible, procedures should be posted near the relevant machine. Machine-specific photographs detailing each step are highly recommended. Photographs have a distinct advantage over written instructions or even graphics because they provide a specific and intuitive visual reference point for workers.

3. Clearly Mark All Isolation Points

All energy control points should be clearly and permanently marked with standardized tags or labels.

Tags and labels should be easily visible. It is also very important to make sure all energy isolation points are consistent with the machine-specific procedures we discussed in tip #2.

4. Develop a Rigorous Training Program

Effective training is an indispensable part of a successful lockout program. It can also be one of the most difficult parts because all workplaces and workforces need to be trained according to their specific needs.

First, it is important for each worker to know exactly what his role is. Tasks should be clearly defined and clearly assigned to the appropriate worker. There are three types of workers involved in lockout operation: authorized, affected, or other. An authorized employee is directly involved in locking out equipment or machinery. An affected employee means any employee whose work is affected by a lockout. Usually, this means an employee who is working on locked out equipment. An employee is classified as other if he or she does not work on the machine receiving maintenance or repair but still works in the same area.

Each worker needs to know what type of employee he is, and strong communication needs to be developed among all workers. Authorized employees must clearly alert all affected employees when a lockout device is placed or removed. In order to prevent unsafe removal of devices, only authorized employees can remove devices that they have placed. Lockout padlocks have room for workers to clearly write their names in permanent ink, which underscores the strong need for clear assignments and individual responsibility.

As with procedures and isolation points, documentation is an important component of training. Recording exactly what types of training have occurred is helpful on several levels. First, it helps management make sure that all workers have been trained, as well as trained in the right tasks. Any gap in training can be easily found and corrected. Second, it documents when training took place, which helps workplaces plan ahead. If you know when your last training session took place, it is easier to plan when the next one should take place. Last, looking at documentation of lockout training can help one see one's program from a new, more objective perspective. Suggestions can then be taken into account and improvements can be made.

Training also should be tailored to each specific workplace. If one has a multilingual workforce, for instance, multilingual training tools, signs, and documents should be used. Workers should be encouraged to relate their specific safety needs.

OSHA requires that lockout/tagout training occur at least annually. Yearly training should be seen as a bare minimum rather than an ideal. In many cases, it would be helpful to revisit training exercises more frequently than yearly in order to ensure that critical repairs and maintenance are still being done safely. Also, repeat training helps workforces keep a "safety first" mentality. When deciding exactly how much training is necessary, it is important to keep workers engaged in the process and to make sure their ideas and concerns are carefully considered.

5. Evaluate

Careful evaluation is an invaluable tool for improvement. The success of lockout training and written procedures can only be truly gauged after they have been put to use in an actual maintenance or repair situation. Evaluation is necessary to make sure that the training exercises, procedures, and devices are working properly. It also affords opportunities to make improvements that may not have been obvious in the training stage.

OSHA provides rules for periodic inspections. These should be followed closely and should provide an excellent foundation for evaluation and improvement. Inspections need to occur at least annually and should be performed by an authorized employee who is not involved in the procedure being inspected. Any and all deviations must be corrected and all roles must be thoroughly reviewed.

The inspection also must be documented. The date of inspection, procedures, the machines and equipment involved, and the names of all workers involved in the inspection must be recorded.

6. Evolve

Lastly, a good lockout program should always be able to evolve; OSHA may introduce more requirements or more stringent guidelines. It is important to make sure your program is up to date.

Open communication between all levels of employment also will help your lockout program reach its potential. A program that encourages communication can identify strengths and weaknesses much more efficiently than a program that remains static and unchanging after initial training. Employees should be encouraged to communicate which training exercises are working well and which ones are not working as well. A lockout program can then go beyond fulfilling minimum requirements: It can be tailored to your workplace and your workforce.

The ultimate goal is maximum safety, and all steps should be taken to reach that goal.

This article originally appeared in the August 2016 issue of Occupational Health & Safety.