The Route to Better Data

Here's how to effectively use your technology to keep your people safe.

- By John Mavros

- Jul 01, 2011

On the heels of workplace disasters such as the BP oil spill and the devastating explosion at West Virginia's Upper Big Branch mine, companies are increasingly turning to technology to keep people safe.

Today, many organizations are using technology to predict workplace injuries so they can prevent them. Safety predictive models are software algorithms that have been trained on historic incident and field-based safety data. When these predictive models are fed real-time workplace safety data, they can make inferences about future outcomes, which can be used by an organization to drive corrective actions to avoid workplace incidents and injuries. For instance, a predictive model can identify work sites or work groups that are most likely to have an injury.

I have been delivering predictive technologies to customers for the past 10 years and have seen the models continually improve and yield even greater impact. However, I have learned that technology alone is not enough. While predictive technologies can identify where injuries might occur, it is humans who must execute the corrective actions to prevent those injuries from occurring. As such, it takes the right mix of people and technology to make your workplace safe.

Further, predictive technologies are only as good as the quality of data going in and the people who execute the corrective plans based on the information coming out. If no one is monitoring the incoming data and its quality, then the data can be considered almost worthless. Just the same, if no one is there to take corrective action on the output of the predictive technologies, again, the output is worthless. Remember the old question, "If a tree falls in the forest and no one is around, does it make a noise?" We all know that it does, however, no one is there to hear it. It is critical for a safety program to be heard and that its message is accurate so the most impactful improvements can be made.

Throughout this article, I will discuss how to effectively use technology to sustain a successful safety program and ensure its messages are heard.

Starting a Safety Initiative

The concept of "Vision, Strategy, Plan," or VSP, is a great way to set the stage for any new safety initiative. Working with operational leadership and key employee leaders to create a safety vision is an important first step. From this vision, a strategy can be developed.

For example, you might have a vision to reduce or eliminate injuries. Your strategy to achieve that vision might be to have all employees collect high-quality safety data that is turned into actionable information through the use of predictive safety analytics. The information can then drive continuous improvement and corrective actions that result in a safer workplace.

Once you have defined your strategy, it's time to plan the details. Some things you might consider are how you will monitor and ensure the quality of your safety data and what steps you should take toward improving the way your organization uses the resulting actionable information.

Once your organization has developed a VSP, the safety data you collect should be aligned to support it. For instance, if your strategy consists of getting employees to collect high-quality safety data, then you need to consider the type of data you want them to collect and then define what "high-quality data" looks like. The next step is to ensure the technology you are using is flexible enough to allow for custom safety data collection checklists to be created and robust enough to measure the quality of your safety data.

Ensuring the collection of high-quality data is the foundation for trust. Trust in your employee's knowledge of safety earns the trust of your operational leadership. One of the primary reasons that operational leadership is reluctant to act on safety information is that they don't trust the data or those who collect it. As a result, safety information is often ignored, and no corrective actions are taken. Intended or not, this lack of action often sends a signal that leadership doesn't care about workplace safety. This then sets in motion a vicious cycle: Employees think leadership doesn't care about safety, so they stop collecting meaningful data, which results in a lack of visibility regarding where corrective actions should occur, which results in an unsafe work environment. It is a pattern that occurs all too often in the safety industry.

Evaluating the Data Collectors

To gain trust in your data and the information derived from it, a system of quality verification should be created. This system can be used to evaluate the people collecting the safety information based on factors such as their level of participation; the amount of information they collect at a determined frequency; the amount of at-risk information they collect; their inclusion or exclusion of meaningful comments; and their willingness to identify high-severity items.

Evaluating your data using these attributes not only will promote quality and thus trust in your data, but also foster trust in the safety knowledge of your people. If an individual's data shows signs of poor quality, you will have meaningful information to provide coaching. Similar to a robust HR evaluation or a performance review program, a safety quality feedback program is much more effective if it is objective and based on metrics that can be benchmarked against one's peer group, rather than subjective and open to individual interpretation or bias.

Evaluating the Safety Data

Depending on the size of your organization, you may or may not be able to manually evaluate the safety data coming in from the field. When you have a sizable organization, technology is critical to evaluating, ranking, and reporting on the quality of your safety data.

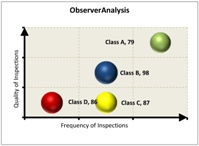

One of the main ways technology can help in this effort is by providing real-time evaluation of workplace safety data and providing reporting that ranks the people collecting it. The graphic shown here gives an example of a high-level classification of employees who are collecting safety data and puts them into categories labeled classes A-D. The technology should then allow you to drill down to get a detailed listing of who is in each category and what attributes they could improve to increase the quality of their data and move up to the next category.

One of the main ways technology can help in this effort is by providing real-time evaluation of workplace safety data and providing reporting that ranks the people collecting it. The graphic shown here gives an example of a high-level classification of employees who are collecting safety data and puts them into categories labeled classes A-D. The technology should then allow you to drill down to get a detailed listing of who is in each category and what attributes they could improve to increase the quality of their data and move up to the next category.

Putting the Data to Use

Once you trust the data being collected, don't forget to use it. A great way to put "action" into actionable information is to create a "Data Use Plan." For each key piece of reporting information collected, the plan ensures its purpose is identified, a person is assigned to review it at a specified frequency, and appropriate follow-up is scheduled. Often, all levels of the organization participate in reviewing safety data, including operational leadership, safety leadership, employee supervisors, frontline workers, and even other interested stakeholders, such as customers, contractors, a board of directors, investors, or owners.

After you create your Data Use Plan, be sure to properly communicate it to all interested stakeholders. In all scenarios, make sure you properly explain your Data Use Plan and communicate to the necessary parties the reporting information they will receive. A mistake that is often made is sending information to a group of people without explaining what it means or, more importantly, what it does not mean. You do not want your safety data to be left for interpretation.

Finally, don't make the mistake of relying on technology alone. The best equation for a safe workplace is a strong safety culture, in addition to the skills of knowledgeable people and utilization of the right technology. Support your safety technology with a strong VSP methodology that both measures and increases data quality, drives trust and thus action, and results in a safer workplace with fewer injuries.

This article originally appeared in the July 2011 issue of Occupational Health & Safety.

About the Author

John Mavros, director of Implementation/Support at Predictive Solutions Corporation, can be reached at [email protected]. Predictive Solutions is a subsidiary of Industrial Scientific Corporation (www.indsci.com). To learn about Predictive Solutions, visit www.predictivesolutions.com.