What Is Involved in a Site-Specific Safety Plan?

When safely operating a truck-mounted crane, you must know your equipment and plan for your job properly. Mobile crane safety training courses can be beneficial to achieving that goal. OSHA-approved classes are arranged to teach inspectors, signalers, contractors, operators, engineers, riggers, and construction managers how to execute heavy lifts safely.

You must ensure that everyone participating in the lift receives training in the basics. Your training objectives should involve understanding:

- Current regulations and standards

- The various types of mobile cranes

- Work site preparation

- What's included in a site-specific safety plan

- The risks involved with crane operation

- Each person's responsibility when it comes to crane safety on construction sites

- How a crane safety plan minimizes the risk of an accident

- Switching between rigging techniques and lifting methods

- How to input a lifting and crane safety program

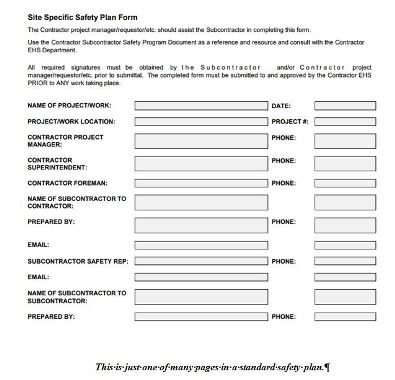

It is necessary to know what's involved in a site-specific safety plan because that is where on-site crane operations detailed planning begins. A construction manager or general contractor usually prepares the site safety plan alongside the subcontractors. The plan includes each phase of safety and describes how specific processes are to be performed. It also contains details that explain the necessary procedures for each lift.

A safety plan that is site-specific helps every business stakeholder abide by OSHA's and others' regulations. It also provides a process for reporting accidents, as well as managing and identifying hazards. When filled out correctly, it will guarantee compliance by doing the following and then some:

- Guarantee a lift plan for production lifts and separate lift plans for every critical lift

- Inspect procedures for the load testing and/or inspection of cranes, both during the course of construction and when they first arrive on site

- Decide where the crane will be during lifts

- Create a procedure for dispersing the plans among all parties

- Designate who will operate the crane

- Be sure that those performing lifting and rigging operations understand proper rigging procedures, and that rigging is supervised

On a large job site, several contractors coordinate their safety programs to prevent omissions, overlap, and conflicts. This consolidated program is what this "site-specific" plan is for. When other stakeholders have their own safety plans, the lift director or general contractor has to create a site-specific safety plan that considers site-specific conditions.

The Job Site

To comply with a site-specific plan, you must first inspect your work zone. Be aware of your closeness to power lines or any other obstacles overhead. Once you’ve figured out the footprint of your cranes and other equipment, you will need to start the site preparation. High axle loads result in high ground pressures, which means you must know what support and other groundwork need to be placed in advance.

Find out where the paths leading to and from the work zone are at the beginning, middle, and end of the project. These zones will be anywhere the cranes, their load, any rigging, or the load line may reach their maximum working radius.

These zones will be assigned in the way your team has decided (typically with range-limiting warning devices or flags). These pre-determined limits protect workers and equipment. Make sure that proper signage is plastered everywhere it’s required and that it can be clearly seen by your workers.

Examine your cranes as well as your other equipment, making sure to keep careful records each step of the way. Have a crane assembly plan that considers procedures necessary to alter the manufacturer’s instructions to a specific job site's conditions. Local regulations might demand certification and/or a third-party inspection prior to operation. Of course, when the lifts are done, you will need to have a dismantling plan in place.

Larry Collier is executive service technician/diagnostic specialist at

Larry Collier Crane Parts & Service, which is located in McDonough, Ga. The company prides itself on being a comprehensive resource for high-quality, factory-stocked crane parts, crane repair and rebuild services, diagnostic assistance, and more.

Posted on Mar 06, 2018