U.S. Department of Labor Cites Manufacturer for 48 Safety, Health Violations Following Employee's Death

PM Engineered Solutions of Watertown, Connecticut faces $236K in penalties.

- By Shereen Hashem

- Jan 19, 2022

An employee of a Watertown, Connecticut metal fabrication company was electrocuted on July 14, 2021, while repairing a portable water heater. An OSHA inspection found that his employer, PM Engineered Solutions Inc., lacked safeguards to protect employees against electrocution, as well as mechanical, chemical, fall and other electrical hazards. OSHA cited the company for 40 serious and eight other-than-serious violations of workplace safety and health standards found during its inspection of the facility. The company faces a total of $236,201 in proposed penalties.

OSHA inspectors determined that the company failed to develop procedures to lockout the water heater's power source during maintenance or provide lockout training to the deceased employee. They also found the company failed to check energy control procedures periodically. The purpose of lockout/tagout is to prevent the unexpected startup or release of stored electrical, mechanical, hydraulic, pneumatic or other energy sources in machines and equipment that can result in serious injury or death to workers.

"This employee lost his life due to the employer's failure to implement required energy control procedures," said OSHA Area Director Dale Varney in Hartford. "Of equal concern is the broad cross-section of hazards throughout the facility. Left uncorrected, they expose employees to being crushed, caught in moving machine parts, burned, chemical exposures, falling and being unable to exit the workplace promptly in the event of an emergency, such as a fire or explosion."

According to a press release, OSHA identified additional hazards during its inspection of the plant, including:

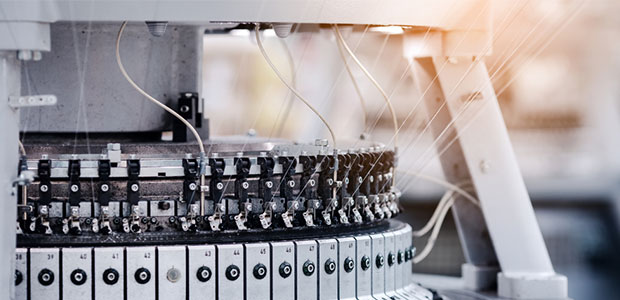

- 62 instances of inadequately guarded machinery, including mechanical power presses, forges, hydraulic presses and grinding machinery

- Numerous electrical safety violations, including exposed live electrical parts, uncovered electrical boxes, flexible cords used in lieu of permanent wiring and material stored in front of electrical panels.

- Open or unlabeled tanks and containers of hazardous chemicals.

- Improperly located or designed collection systems for combustible dust.

- Lack of PPE for employees.

- Unsecured or improperly stored compressed gas cylinders.

- Lack of a permit-required confined space program for employees who regularly entered a machine pit.

- Uninspected damaged and unmarked chain slings.

- Uninspected, inadequate and improperly altered powered fork trucks.

- Failure to periodically evaluate fork truck operators' performance.

- Missing or inadequate exit signage.

View the citations here and here. PM Engineered Solutions Inc. has 15 business days from receipt of its citations and penalties to comply, request an informal conference with OSHA's area director or contest the findings before the independent OSHC.

About the Author

Shereen Hashem is the Associate Content Editor for Occupational Health & Safety magazine.