What Reopening Means for Each State

Workplaces across the nation begin to reopen, but not all are operating with the same methods, or cautions. Here’s an outline of what each state is doing, according to a June 4 NPR article.

With little to no federal guidelines on how to reopen workplaces during the COVID-19 pandemic, states are left largely up to their own decisions on how to proceed. As of May 20, all 50 states have begun the process of easing restrictions on businesses, though public health experts say some are moving too quickly.

At a May 12 Senate hearing, Dr. Anthony Fauci, the U.S.’s top infectious disease expert expressed concern about some states and localities skipping federal guidelines to reopen prematurely.

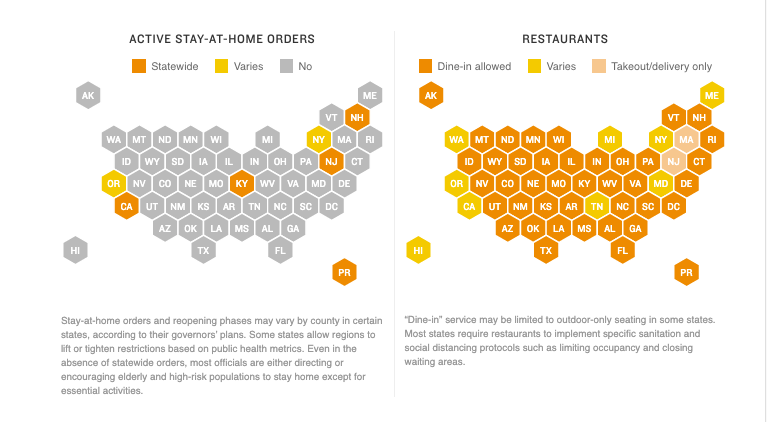

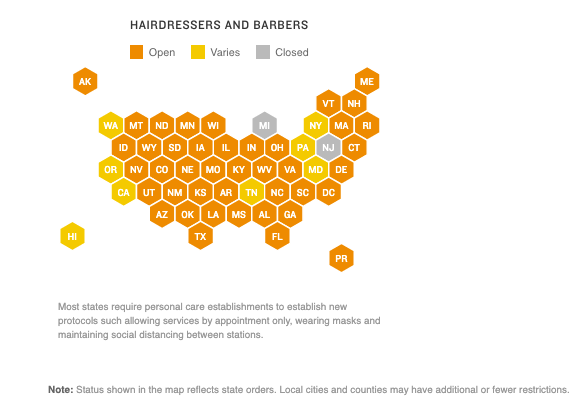

Below are some graphs provided by NPR to show which states, as of June 4, have done away with stay-at-home orders, opened restaurants and begun operating hairdressers/barbers.

By and large, state officials are working to develop plans to reopen economies and protect public health. Governors are outlining frameworks and timelines for their states as they ramp up testing and contract tracing efforts. Most are releasing general and sector-specific reopening guidelines for industries and individuals.

The article outlines what each U.S. region is doing specifically, and you can read about the northeast, midwest, south and west regions and their state decisions on reopening.

While most states have done away with their stay-at-home orders, many regions still highly recommend that individuals limit outings to only essential errands—and nearly all recommend people continue to social distance and wear masks.

“Governors in states such as New York, California, Washington, Pennsylvania and Maine have enacted plans that allow regions that meet certain criteria to progress through reopening phases at a faster pace than the rest of the state,” said the article. “Other states, such as Virginia, New Mexico and Utah, have delayed reopening timelines for particular counties based on public health metrics. And within many states, local governments may be authorized to implement tighter or looser restrictions in their own jurisdictions.”

Once they open, many establishments must follow specific protocols, including limiting building occupancy and requiring employees to wear face masks.

Even though states have begun to reopen under their own terms, the CDC still has published recommendations for a number of industries including office buildings, schools, nursing homes/care facilities, pharmacies, agriculture and other spaces.