Finding the Right Machine Safety Partner for Your Company

Here's what EHS pros need to know about machine safeguarding.

- By John Peabody

- Feb 01, 2017

As a safety professional, you work every day to ensure employees are safe and productive. You provide the appropriate training, reinforce basic safety concepts, and provide necessary PPE. You are familiar with the requirements for confined space restrictions, forklift protocols, and even have taken classes to ensure that workplace violence is prevented.

Then production calls you and says that the new safeguarding on a machine is preventing them from making quota. The wheels come off.

You're not alone. EHS professionals are well schooled in virtually every aspect of health and safety except for the details of machine guarding. After all, the machine guarding section of OSHA is a tiny fraction of OSHA's hundreds of rules. Nonetheless, year after year, two of the top 10 most-cited OSHA regulations are machine guarding related (Section 1910.212, the general machine guarding clause, and section 1910.147, lockout/tagout). Why is this crucial area of industrial safety so difficult to master?

OSHA addresses specific machine guarding for only a handful of machine types, those in most common usage in the 1960s. Nowhere in OSHA is there a reference to industrial robots or water-jet cutting machines. So the question is how today's EHS professional can ensure machinery is guarded in compliance with current standards, while simultaneously allowing workers to run the machines productively.

The key is expertise. More perhaps than in any other discipline, the use of experts is necessary because OSHA requirements do not clearly address the machines in today's facilities. The general machine guarding clause is simple. It states: "One or more methods of machine guarding shall be provided to protect the operator and other employees in the machine area from hazards." Nothing to it. The challenge is how to protect the operator from machine hazards while still allowing him to be productive. How do you find the right solution for your machine safety needs when machine safeguarding is most likely not a core competency of your staff?

There are basically two parts to machine guarding. First is the hazard identification process, most commonly called a risk or machine guarding assessment. Second, and possibly the more important, is the Risk Reduction evaluation. The Risk Reduction part considers: How will the risk be mitigated, and what methods of guarding will be most appropriate for your machines?

Evaluating Your Machine Safeguarding Services Vendor (Partner)

Questions and considerations for finding the right machine safety partner for your company follow:

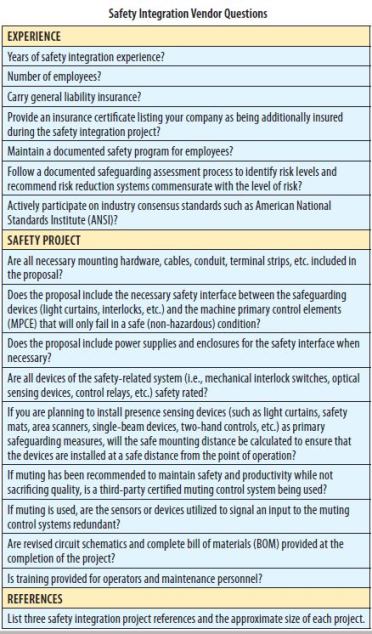

1. What level of experience does the company have and specifically the person(s) who will do your risk assessment and possibly remediation? Are they familiar with the machines and processes that you have? Do they know and understand the applicable regulations and standards involved, such as OSHA, ANSI, or ISO?

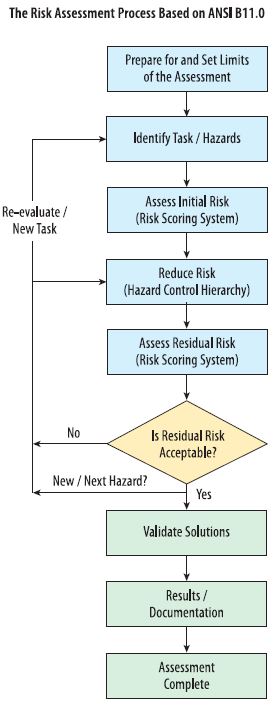

2. Do they use a repeatable and recognized process? What standard does the process adhere to? It is best to use a standard like ANSI B11.0-2015 and not to reinvent the wheel. The assessment process in the most current version of ANSI B11.0 states the following steps:

a) Prepare for and set limits of the assessment (which machines to be assessed, who will be on the assessment team, how to document, what are the scope and limits for this assessment, how to score risk, how to prioritize, what is the acceptable risk level, etc.).

b) Identify tasks and hazards. (Define the tasks involved. Many machines that are identical can be used in different ways. Your specific uses are critical information. Machine operators and maintenance personnel should be involved with this process.)

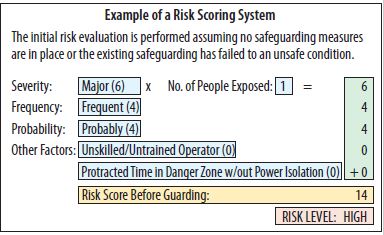

c) Assess initial risk. (Use a repeatable and reliable scoring system to score risk for each identified hazard.)

d) Reduce risk. (Use the Hazard Control Hierarchy and apply risk reduction guarding concepts to reduce risk. It is very important to have operators, maintenance, and production personnel involved in the review and buy-in of the risk reduction guarding concept before it is actually installed.)

e) Assess residual risk level. (With the agreed-upon risk reduction concept in mind, determine whether acceptable risk has been achieved.)

f) Has acceptable (tolerable) risk been achieved? (If yes, implement the risk reduction measures and continue in the next step. If no, re-evaluate risk reduction measures and work to reduce risk.)

* This issue of tolerable risk deserves significant reflection within your organization. Some companies define tolerable based on lost work day accidents, others rely on the guidance of their insurers, but without a clear understanding of what is tolerable to your company, there is no end to the risk reduction process. What is tolerable to one is not necessarily tolerable to another. It behooves you to ensure that your definition of tolerable risk is clearly defined and understood by your risk assessment vendor. Please keep in mind that you need to comply with government regulations.

* Implement the agreed-upon solution. Make sure you get buy-in from the users. This is possibly the most important point in this discussion, because if the machine operators and the maintenance people do not buy into the new safeguards, they will find a way to defeat or override them. Trust me! It is truly amazing to witness the lengths people will go to in order to work around an inefficient safeguard.

g) Validate the risk reduction solution. (Once the guarding concept—solution—is installed, the system needs to be tested for effectiveness and proper operation. Test all safety devices and circuits and document the results. Review and update safe work procedures, maintenance procedures [LOTO]. Train all applicable personnel on the newly installed safety systems and updated procedures.)

h) Document the process and results. (Document the assessment process, scoring method, risk levels, risk reduction methods, residual risk, validation results, safe mounting distance calculations, training, and sign-off.)

3. To further qualify your machine safeguarding partner, ask: "What kind of assessment report will you get?" and "What should it include?" The information in the assessment report is critical for the machine guarding decision-making process. Does the report include or identify:

a) the process used;

b) the standards applicable to the machine;

c) the identified Risk Level;

d) the required safety related control level (based on the risk level and selected guarding concept);

e) the guarding solution, including selected safeguarding devices and a clear description or diagram of the solution;

f) the residual risk (there is always residual risk; no guarding scheme reduces the risk to zero); and

g) the corrective action or remediation priorities (which machines need to be addressed first, second, third, etc.).

4. What do they provide with their solution?

a) Do they perform a stop time measurement on the equipment to ensure the safe guarding devices are placed at the proper safe mounting distance and location? Do they provide the results of that test?

b) Do they provide adequate documentation for the materials (BOM), wiring, and interface schematics at job's end?

c) Do they have a process for training your people and returning the machine to production?

d) Do they provide a completion guarantee?

5. Do they have the appropriate level of Professional Liability or Errors & Omissions Insurance?

6. Is machine safeguarding their core competency?

After you have done your due diligence in selecting a risk assessment vendor, you can sit back and relax, right? Well, maybe. The risk assessment process is only half the battle. The trickiest part of your selection process must focus on the risk reduction strategy your expert (partner) proposes.

Some of the issues you should be comfortable with include:

1. Are the devices selected all safety rated? Have they been designed for safety applications and not just industrial ones? Do they meet international standards for such products?

2. Is the installation of the selected devices done to applicable standards? Are qualified personnel used? Have all safe distance calculations been verified and documented after the safeguarding has been installed?

3. Does the solution maximize the operator's ability to run and maintain the machine? Have maintenance concerns been fully addressed? Are operational changes required to run the machine once the safety solution has been installed?

4. If production is negatively affected, why and by how much? Are there alternatives that have been considered to minimize the negative effect on production?

5. If programmable safety devices are used, are back-up programs and software supplied? What if a change is required after installation? Who is responsible, and what is the process to implement a change?

6. What is the warranty period for parts and labor?

7. Whom do I call for technical support or additional training?

Clearly, there are a lot of moving parts when it comes to selecting the right machine guarding safety services partner. Ideally, this selection will result in more of a partner then a vendor because the decisions made will affect your employees' working environment for years to come. Moreover, it is unlikely you will end up guarding everything at once. Your selection may (probably should) wind up resulting in a long-term relationship that bridges existing and new equipment. A good machine guarding vendor (partner) will know which new and or used equipment may be more viable from both a productivity and safety point of view. You should feel confident that your selected machine safety services partner will bring a working knowledge of the existing standards and a keen eye to making your factory floor safer and more productive.

This article originally appeared in the February 2017 issue of Occupational Health & Safety.