Formula for Improving Safety Culture

Good or bad, you have already created a safety culture.

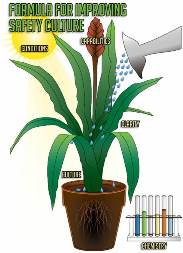

What kind of safety culture do you want to grow? Safety culture is more organic than most models describe. It is not a perfect linear process, nor is it an organizational chart or a gradual model of evolution. Forming a safety culture is more like growing a plant. If the right capability seeds are planted, leaders must then create clarity and control the climate, chemistry, conditions, and common practice for the culture to have a chance at excellence. (See the Figure: Formula for Improving Safety Culture).

Unless you are building a new facility or starting a new project staffed with individuals who have never worked together before, your safety culture already exists. Culture is what is common within a group. There are already common beliefs, rules (written and unwritten), knowledge, behaviors, and capabilities specific to safety. Good or bad, you have already created a safety culture.

As we advised in our 2013 book, STEPS to Safety Culture ExcellenceTM, outlined below is a simple formula for improving your safety culture toward excellence:

1. "Develop a Safety Strategy" – The first S in STEPS stands for "Strategic." It is impossible to set a strategic target if you don’t have a strategy. Most organizations, quite frankly, don't have a safety strategy. They have goals, wishes, programs, and metrics, but all these don't really have a framework that brings them together. An effective strategy can help focus on the right, measurable goals of achieving excellence rather than avoiding failure.

2. "Perform an Assessment of your starting place" – Determine what kind of safety culture you already have, what strengths can be utilized, and what additional capabilities it needs to improve. Understand your starting point and use it as a baseline to measure further improvement.

3. "Create Clarity of purpose" – Deploy your safety strategy, organize and train the members of the culture at every level in the strategy to learn the basic definitions of safety and the improvements needed. Especially teach the culture the basic skill of targeting and accomplishing what we call STEPS. Share the rationale for improvement, how the organization will benefit, and answer the WIIFM (what's in it for me?) question. Structure a Safety Excellence Team (SET) to steer the organization through the STEPS.

4. "Create the right safety Climate – Create or improve the organizational climate in which a safety culture can grow into its personal best." For more detail, read "Controlling the Climate of Safety Culture" (OH&S Magazine, April 2016).

5. "Create the right safety Chemistry – make sure the culture has the elements necessary for safety excellence growth and that these elements are renewed as they are utilized." For more detail, read "Evolving Your Safety Culture: Elements that Matter Most" (OH&S Magazine, July 2014).

6. "Create the Control to address the issues of Conditions and Common Practice that impact safety." Prioritize and address your safety issues one at a time.

7. "Your Safety Culture Can Now Continuously Improve Safety. Re-assess, measure and adjust – recognize progress and barriers and react appropriately and flexibly to meet the changing needs."

Too often, attempts to improve safety culture focus on describing the characteristics and aligning attempts to be more like other companies that embody these features. While one can learn from better practices of others, real success involves improving capabilities and managing the elements influencing the byproduct of culture, rather than attempting to transform characteristics.

Cultures are a constantly changing set of influences that shape common practice. Instead of describing what your culture should be like, identify what your culture should do. What capabilities are needed? What should be common? What strengths already exist? Safety cultures don't become excellent by simply being less bad. True excellence is achieved by building on existing strengths and developing new ones.

Planting capability seeds within the culture will not ensure they will grow. Your safety climate and chemistry must be controlled. If the climate is not conducive to growth and the chemistry does not provide the necessary elements, the capabilities may wither or die. When these are controlled, however, you can prune and shape your culture and make adjustments along the way to maximize potential. Your safety culture is already growing in your organization. Are you shaping what creates it or are your efforts to improve being shaped by it?

This article originally appeared in the August 2016 issue of Occupational Health & Safety.