Chinese Spaghetti Factory Faces OSHA Fines Over Unguarded Equipment

The Boston company’s investigation initially focused on an unsafe dumpling machine.

- By Robert Yaniz Jr.

- Jul 26, 2023

After an employee was injured at Chinese Spaghetti Factory Inc. in 2022, the U.S. Department of Labor (DOL) performed a follow-up investigation into the Boston-based food manufacturing plant.

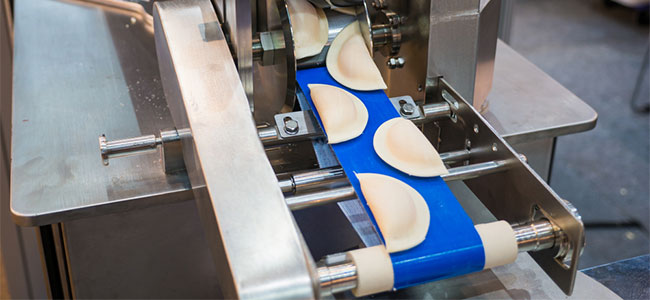

In a release dated July 24, OSHA announced the findings of its March 2023 investigation. During this visit, OSHA discovered the dumpling machine which was part of its 2022 citation still didn’t have the required safety guards in place to protect workers from its rotating shafts. Chinese Spaghetti Factory faces a proposed $82,500 penalty for this repeat violation.

OSHA investigators—along with health inspectors—found other violations amounting to an additional $108,031 in penalties. These include a willful violation for the unguarded dumpling machine unguarded, two repeat violations for unguarded machinery and electrical components, a serious violation for having no procedure to prevent unintended equipment activation and three serious violations related to high noise levels, eyewash facilities and an incomplete chemical hazard communication program.

"The sizable penalties in this case reflect the gravity of this situation and the dangers faced by people employed at the Chinese Spaghetti Factory's facility," OSHA Area Director James Mulligan in Braintree, Massachusetts, said in a statement. "The employer's willingness to ignore federal regulations and failure to correct workplace hazards, including one that seriously injured a worker, is unacceptable.”

Chinese Spaghetti Factory currently faces a combined $190,541 in proposed penalties. Since 2017, OSHA has cited this same location with 10 serious, repeat, and other-than-serious violations. The company now has 15 business days to comply, request an informal conference with OSHA or contest its findings.

About the Author

Robert Yaniz Jr. is the former Content Editor of Occupational Health & Safety.