Expert Tips for Working Safely in Confined Spaces

Water treatment workers that enter ducts, manholes and vaults frequently must know these safety tips for confined spaces.

- By Mark Heuchert

- Oct 01, 2020

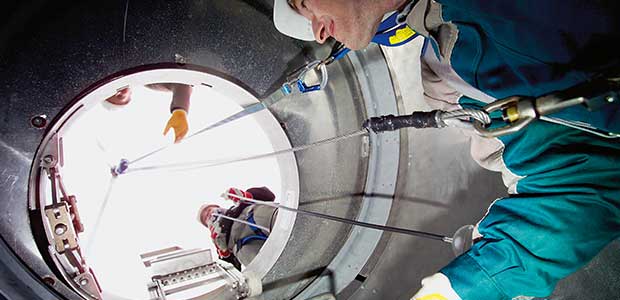

Little space, lack of oxygen and hazardous substances: Workers in the water treatment industry who enter the confined spaces of ducts, manholes and vaults need to trust that they can also get back out again safely.

Danger Lurks in Confined Spaces

The cleaning, maintenance and repair of canals and shafts is a common task in the wastewater treatment industry, yet it is anything but routine. This is because the necessary entering of these “confined spaces” is one of the most dangerous tasks workers face. But when is a confined space defined as such and thus deemed to be particularly dangerous?

Although the definition of a confined space varies between jurisdictions, which leads to numerous local regulations, it is generally recognized by OSHA as a space that:

- Has a limited means of egress

- Is not designed for continuous occupancy

OSHA further clarifies that confined space is considered Permit Required Confined Space if, in addition to the above, also has any one of the following:

- Can asphyxiate or trap the worker

Many workplaces contain areas that are considered "confined spaces" because while they are not necessarily designed for people, they are large enough for workers to enter and perform certain jobs. As indicated above, confined space also has limited or restricted means for entry or exit and is not designed for continuous occupancy.

Confined spaces include, but are not limited to: tanks, vessels, silos, storage bins, hoppers, vaults, pits, manholes, tunnels, equipment housings, ductwork, pipelines, etc.

Working within confined spaces not only requires an experienced team and practice, but also the necessary technical equipment. Only then is it possible to measure the rooms to exclude toxic or explosive substances and to initiate any required rescue measures. In many countries, employees who perform confined space entry work have to present appropriate training certificates. This includes the use of gas measurement devices and full knowledge of personal protective equipment (PPE).

The Statistics

The International Labor Organization (ILO) of the U.N. and OSHA estimate that worldwide around 200 people die each year due to accidents in confined spaces in industry, agriculture and private households.

Official national statistics rarely contain all accidents and the precise extent of its consequences (type of injury, severity of the injury, deaths). According to a study performed by the University of Berkeley, the situations with the highest accident rates are repair and maintenance work (24 percent of recorded cases), followed by cleaning work (12 percent) and inspections (11 percent).

Most Common Causes of Accidents

The causes of accidents which occur during confined space entry work in the wastewater treatment industry vary. They include a lack of or insufficient assessment of the danger, underestimating the danger or the use of personnel which doesn't have training for confined space entry work, despite all of the regulations. Other potential causes include underestimating the concentration of gases inside the canal or structure (oxygen content, explosion risk, toxicity) or unexpected biological processes such as rotting and fermenting processes.

There is a risk of losing consciousness due to a lack of oxygen and suffocating, or absorbing poisonous bacteria or viruses through the skin, mouth and respiratory systems. Falls can occur as well, due to faulty crampons or accidents resulting from increased material wear due to aggressive substances in the work environment. Ignition sources, such as electrical machines, which can spark, are dangerous as well.

Despite all safety precautions, entering confined spaces will always pose risks because the conditions inside cannot be predicted with 100 percent certainty. Therefore, before work is performed in confined spaces, it is imperative to always check whether it can be performed from outside the space in order to help prevent accidents.

Taking Correct Clearance Measurements

Workers and/or supervisors may have received training on how to behave in confined spaces, but they may not have insufficient knowledge of how to use gas measurement and breathing protection equipment. Knowledge, skill and experience are often lacking even when it comes to checking the atmosphere inside a space immediately before the start of work. Errors in judgment often result because the measurement is taken at the wrong location: During entry into a shaft, it is possible for CO2 or in the case of wastewater treatment facilities, digester gas (a mixture including CH4, CO2, H2S, O2 and H2), to have formed and settled at different heights. This means that the atmosphere can appear safe when measuring from a safe position, while dangerous gas concentrations are present when the person enters, moves around and begins work in the shaft.

Thus, it is important for workers in these areas to always carry a mobile gas measurement device and emergency escape equipment directly on their bodies. Continuing with the wastewater treatment facility example, in addition to digester gases, gases which are flammable and/or poisonous at certain concentrations are typically found, and include CH4, CO2, H2S, O3, CL2, NH3 and volatile organic compounds. The formation of digester gas can also result in a lack of oxygen. An elevated oxygen concentration, due to leaking lines on welding equipment, can lead to the spontaneous combustion of oils and fats. To ensure that workers while working in confined spaces are protected when gases are present, they should use breathing protection.

Accidents can also happen if the wrong sensors are used—an explosion sensor, for example, only detects whether an explosive concentration of a gas is present. Some toxic concentrations are so low that they aren't detected by an explosion sensor, even though a risk of poisoning already exists. This is because an explosion sensor normally only measures the volume percentile in order to detect the risk of an explosion. It does not indicate the risk of poisoning which can exist even in the ppm (parts per million) range.

Why are rescue attempts so risky? A majority of confined space entry related deaths occur during rescue attempts: Colleagues often act on impulse without carefully assessing the situation first. Rescuers often die for the same reason which endangered their colleague in the first place—due to losing consciousness as a result of gas, which also affects the rescuer if he or she undertakes the rescue attempt without adequate breathing protection and training.

Once an accident has occurred, the confined space entry-related restrictions such as a small access opening, reduced visibility and often insufficient equipment hamper the rescue efforts. And every second counts when it comes to rescuing victims in confined spaces, especially in toxic or oxygen-poor atmospheres.

How can accidents be better avoided? Training is an important prerequisite for accident prevention in confined space work areas. This training should include both theory and practice and simulate a typical situation at work. The training should start with taking the necessary clearance measurements and putting on PPE, followed by entry and exit exercises. Participants should also receive training on how to evacuate unconscious and injured persons, as well as, how to behave under stress and in environments with poor visibility. Knowledge of the typical confined space entry procedure plan is also helpful in order to thoroughly prepare for a safe deployment.

A rescue plan must always be prepared. Furthermore, specific emergency plans often don't exist in practice, or the workers are unfamiliar with the plans. Outside rescuers may have insufficient training in confined space rescue, so they have to make time-consuming preparations in light of the high risks associated with these rescue attempts. This can significantly delay the start of rescue measures, with potentially fatal results since saving lives requires a fast response. Developing a “what-if” plan ahead of time is extremely important for this type of work. It is also necessary to have a trained rescue team at the ready, which can show up with breathing protection and other equipment.

As a rule, the in-house occupational health and safety staff is responsible for discussing and practicing specific rescue scenarios with the team onsite before starting the work. Therefore, this sort of rescue plan is always specific to the situation.

It is possible to permanently reduce the number of life-threatening and deadly accidents during work in confined spaces in wastewater treatment facilities. The way to achieve this is by observing the applicable occupational health and safety guidelines, the list of hazards and measures within the plant, individual work instructions and the necessary training certificates. Whomever goes into these confined spaces must have the confidence that they can get back out again safely.

This article originally appeared in the October 2020 issue of Occupational Health & Safety.