How to Leverage an Unexpected Plant Shutdown to Improve Your Electrical Safety Procedures

When unexpected crises, like COVID-19, cause unexpected shutdowns, safety managers should capitalize on the opportunity to reevaluate safety procedures across the board.

- By Pam TenHoven

- Apr 14, 2020

As the old saying goes, when life gives you lemons, make lemonade. Well, there’s certainly no shortage of lemons these days. COVID-19 is impacting every level of business operations on a global scale, and no industry is impervious to the resulting production delays and shutdowns.

These challenges are forcing companies everywhere to assess current processes, especially as they relate to safety, and redefine “business as usual”—therein lies the opportunity to squeeze something positive out an otherwise bad situation.

When potential hazards cause an unexpected plant shutdowns, safety and plant managers should capitalize on the opportunity to evaluate and improve safety procedures across the board and deploy new ways to assure workers that the company has their best interests in mind.

Often during plant shutdowns, floor employees may feel confused or be filled with uncertainty.

Managers should seize this chance to increase communications and encourage employee engagement regarding company safety protocols and update existing ones.

Overhauling protocols can feel overwhelming when it’s unclear what should be prioritized, so it helps to start with something that’s already well understood and can be assessed and upgraded efficiently, like electrical safety.

Why Your Electrical Infrastructure Must be a Maintenance Priority

Simply stated: properly maintained equipment is safer to operate and leads to fewer unplanned interruptions.

Shutdowns related to a lapse in regular maintenance are preventable but may lead to a reduction in employee confidence and productivity. Employees may lose faith in management, the equipment’s reliability and job security.

Production numbers will decline, costs will rise, and momentum will be lost.

Prioritizing electrical maintenance will increase safety and decrease property risks. Be careful not to overlook the obvious—even new equipment requires a proactive maintenance and service program. By doing so, that new equipment will continue to run like new, therefore maintaining its value over a more extended period-of-time or, in other words, slowing its depreciation.

Best Practices for Electrical Safety Auditing & Planning During an Unexpected Shutdown

Explore New Innovations. It’s essential to realize now is a great time to revisit electrical specifications to see what new technology can be incorporated. Often, these electrical safety innovations will not only improve safety protocols but also reduce costs and increase productivity.

- Seeking out technologies that provide multi-prong benefits can show organizational leaders that these technologies offer operational and cultural advantages along with added safety.

Involve the Team. Exploring opportunities to standardize electrical safety procedures throughout a facility or across multiple facilities will help establish a safety culture throughout your organization.

- Consistency in messaging, communication distribution and processes will provide clarity while increasing employee and upper management buy-in.

- Plant shutdowns allow for a physical walk-through of plant operations and safety procedures, and these hands-on and visual exercises can reveal gaps in safety or maintenance operations.

- Encourage floor employees to participate in the walk-through, so they are engaged and feel ownership over the process.

- Safety procedures often vary from department to department, shift to shift, or location to location. Over time, workers may have gotten complacent, adopted bad habits or incorporated short-cuts for several reasons, including pressure for increased productivity, lack of supervision or inadequate safety training.

- Taking an internal survey or walk-through with plant or safety managers and floor employees will help nurture electrical best practices company-wide.

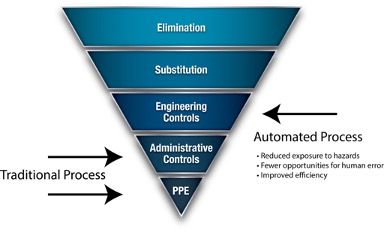

Use the Hierarchy of Controls as a Guide. Look for ways to reduce risk and increase business value by leveraging the Hierarchy of Controls as well as ways to design out hazards.

- Engineering Controls are automated processes that reduce exposure to hazards and opportunities for human error while improving efficiencies.

- They involve a physical change to the workplace itself, rather than relying on workers’ behavior to follow administrative controls or requiring workers to wear protective clothing.1

- An example of an engineering control would be an Absence of Voltage Tester or AVT.

- Ask yourself and your team: Are there processes or technologies to incorporate an engineering control into this safety or maintenance process?

- Remember to think outside of the box and investigate new electrical safety technologies.

Work Within Predetermined Budgets

The cost of doing business safely and responsibly requires profound accountability. Electrical hazards in the workplace can cause fatalities and inflict a devastating impact on workers with debilitating and potentially disabling injuries that can cost millions of dollars in treatment. These impacts create a massive financial burden for any company, in addition to the human toll.

There have been significant advancements in safety technology, and with new products coming to the market, it’s entirely possible to reduce risk and financial worry by investing in electrical safety. The hardships are hard to ignore, especially when we consider that minor electrical incidents in the workplace often go unreported.

Furthermore, according to the National Safety Council’s Safety + Health Magazine, the most common cause of arc flash accidents is human error.2 This is a hard fact to swallow, considering the investment of time to train a qualified electrical worker is significant.

An outdated, under-emphasized or ill-communicated electrical safety program is a financial disaster waiting to happen.

Three Quick Tips to Reduce Financial Risk

Think about integrating technology that will minimize the chance of human error. Will new, permanently installed test equipment upgrade the plant’s ability to create an electrically safe work condition?

Think about user adoption. Can qualified electrical workers be better trained? What tools and equipment will create better efficiency, so they’re put in a safer environment?

Think about the current safety processes the facility employs today. Where can improvements be made that will make compliance with standards even easier and reduce human error?

Even trained experts can experience accidents, but a well-informed Safety Management Team can be a significant asset to the company by keeping the investment in electrical safety a top priority.

It’s essential during a time of uncertainty, as an unexpected shutdown, to convey a cultural message of strength and unity to your employees.

Showing a dedication to electrical safety on the plant floor will nurture that message by illustrating your commitment to their safety. Encouraging them to participate in the electrical safety process will foster their ownership and adoption of the procedures.

Use this downtime wisely, and you’ll reap the benefits when you’re back to business as usual.

REFERENCES

1 “Hierarchy of Controls” The National Institute of Occupational Safety and Health. Retrieved 03-31-2020.

2 “Human error often causes arc flash accidents” National Safety Council Safety + Health Magazine. Retrieved 3-31-2020