Helping Healthcare Facilities Fit Test Respirators More Quickly

As the world is responding to the COVID-19 outbreak, fit testing respirators for healthcare workers and first responders remain vital to respiratory protection programs to reduce exposure to the disease. According to the CDC, the effectiveness of N95 respirators to control exposures to airborne infectious diseases is highly dependent on proper fit and use. In other words, your respirator protects only as well as it fits. As the COVID-19 virus is an airborne inhalation hazard, respiratory protection from properly fit-tested filtering facepieces (such as NIOSH-certified N95s), can help prevent the spread of illness.

All workers and staff with a need for respiratory protection depend on good training to properly optimize the fit of respirators for protection from respiratory (inhalation) hazards, such as physical, chemical, and biological hazards. Respirator fit testing, as part of a written respiratory protection program, can help ensure required protection levels through a properly sized and donned respirator. Passing a quantitative respirator fit test verifies that the respirator is the proper size and donned correctly. It also provides a valuable opportunity for training employees about achieving the correct mask fit. As outlined by OSHA, a "fit test" tests the seal between the respirator's facepiece and your face. The test is required to be performed at least annually for those required to wear a respirator for their job.

However, during public health emergencies like the COVID-19 outbreak, it may be necessary to fit test more staff than usual. In some cases, those already fit-tested may need additional testing to assess new masks received from the National Stockpile or if different respirator types are used.

How the Respiratory Protection Standards Have Changed

OSHA recently announced changes to its Respiratory Protection Standard. The changes affect the Ambient Aerosol Condensation Nuclei Counter (CNC) Quantitative Fit Test (QNFT) Protocols in 29 CFR 1910.134, Appendix A. These changes took effect in September of 2019.

The Modified CNC QNFT protocols are now faster and more streamlined compared to all other fit test methods. The new protocols require fewer and shorter fit test exercises. Instead of eight exercises, the new Modified CNC protocol rules require four. Total fit test time is reduced from 7:15 minutes to 2:29 minutes.

Previously, CNC fit test protocols required a series of eight test exercises, performed in the following order: normal breathing, deep breathing, turning head side to side, moving the head up and down, talking, grimacing, bending over, and then normal breathing again.

The new Modified Ambient Aerosol CNC protocol for full-facepiece and half-face piece elastomeric respirators is different from the original protocol in that:

• It includes four of the eight original test exercises (bending over, jogging, head side to side, and head up and down).

The new Modified Ambient Aerosol CNC protocol for filtering facepiece respirators differs from the original protocol as follows:

• It includes four of the eight original test exercises (bending over, talking, head side to side, and head up and down).

Fit test compliance guidelines and recordkeeping remain the same. In reducing the number of exercises and exercise times, the total time needed for a fit test is drastically reduced. OSHA believes the new rules will end up saving employers considerable time and money, while also reducing the burden of compliance and increasing safety.

How to Make Respirator Fit Testing 65% Faster

Respirator fit testers using the modified CNC protocols such as the PortaCount® Respirator Fit Tester, are now nearly twice as fast as instruments using the controlled negative pressure (CNP) REDON protocol and 65% faster than the original CNC protocols. Whether fit testing medical teams, industrial workers, or first responders, respiratory protection programs will benefit. The test remains rigorous, is fully automated, and provides quantitative fit testing across all respirator types. It also dramatically increases the number of people you can fit test in a set time with no compromises on safety and health.

PortaCount® Respirator Fit Tester Compared to Qualitative - A Healthcare Example

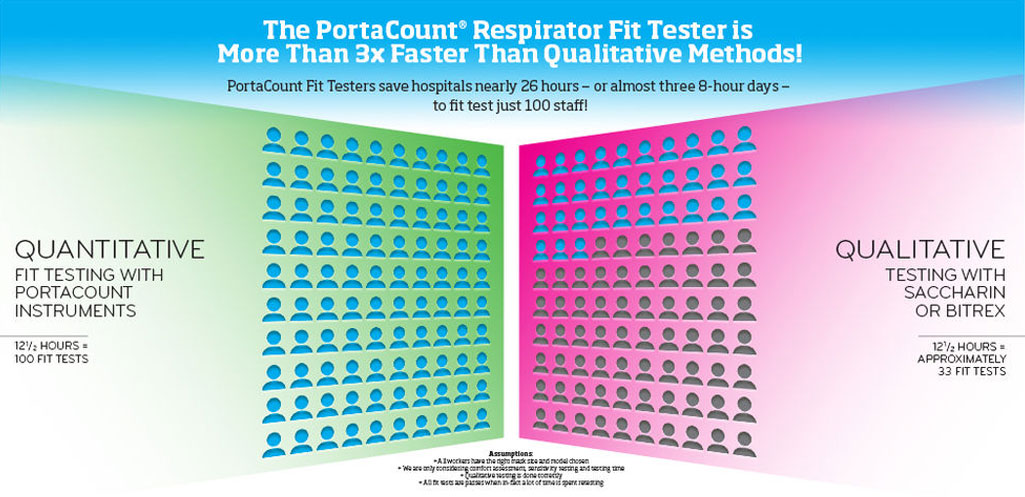

Many healthcare facilities use manual, time-consuming qualitative fit tests that use Saccharin or Bitrex as the challenge agent. According to OSHA, those methods take 7 minutes for the seven-step protocol. Additional steps like threshold testing, a mandatory wear-off period, and an OSHA required comfort assessment period add even more time, totaling 23 minutes or more per fit test.

A fit test using a PortaCount® Respirator Fit Tester finishes in less than 2 ½ minutes for any respirator, including any N95 mask. Adding the pre-test 5-minute comfort assessment, users can complete a fit test in 7 ½ minutes.

We wanted to learn how this difference in fit testing time could affect hospitals that now face large-scale crisis scenarios around the world. The comparison was dramatic.

Qualitative Fit Testing with Saccharin or Bitrex for 100 staff with N95s

- At approximately 23 minutes per test, which includes:

Threshold Screening Test - 1–3 minutes (approx.)

Threshold test wear-off time - 10 minutes

Comfort assessment - 5 minutes

One OSHA compliant fit test - 7 minutes

Total Fit test time = 38.33 hours

Quantitative Fit Testing with PortaCount® Respirator Fit Testers for 100 staff with N95s

- At approximately 7.5 minutes per test, which includes:

Comfort assessment - 5 minutes

One OSHA compliant fit test - 2.5 minutes

Total Fit test time = 12.5 hours

PortaCount® Fit Testers can save hospitals nearly 26 hours— more than three 8-hour work days—to fit test just 100 staff. Imagine the saved time for those fit testing hundreds or thousands of hospital staff.

More Information about the Modified CNC Protocols

Employer Adoption

The rule does not require an employer to update or replace its current fit-testing methods if the fit testing methods currently in use meets existing standards. However, OSHA believes these new Modified variations of the Ambient Aerosol CNC fit testing protocols gives employers greater flexibility and reduces the burdens of complying with OSHA's respiratory protection standard.

State Adoption

States administering state-specific workplace safety and health programs are not required to adopt the modified protocols. OSHA does strongly encouraged states to implement the new protocols to provide employers additional compliance options.

Frequently Ask Questions To start using the new protocols:

Do I have to change my program or procedures?

No, with the new protocols, you select the mask you are testing and the protocol matching that mask. How you use the instrument and the outcome of a fit test is the same; the test is just quicker.

Do I need to redo old fit tests?

No, this is simply a modification to the existing protocol. Fit tests using the previous eight-step protocol are still valid. The only difference is that now there is an option for a shorter test going forward.

How do the new protocols make more workers safer?

This shorter and simpler fit test makes compliance easier without compromising worker safety. An easier path to compliance means more workers will pass quality fit tests, increasing compliance rates, and overall worker safety.

TSI’s PortaCount® Respirator Fit Tester delivers an objective fit test for any respirator, including all N95s, in less than 2½ minutes. Using OSHA’s newly modified CNC protocols, fit tests can now be completed 65% faster than with qualitative methods. With PortaCount Respirator Fit Testers, users will dramatically increase the number of fit tests they can complete in a day. Simplify your respirator fit testing program. One instrument, any respirator, 2½ minutes. Learn more about how you can achieve a better respirator fit for your workers at Modified CNC Protocols or the PortaCount® Respirator Fit Tester.