Why Ergonomics is Not Enough

People have been trying to solve the problem of musculoskeletal injuries for years. However, ergonomics is simply not the whole answer.

- By Benjamin Kanner

- Jan 23, 2020

It’s widely acknowledged that overexertion injuries, mostly showing up as musculoskeletal injuries or MSIs, are a big problem. In the latest year of data (2017), the National Safety Council found that 295,830 or 33 percent of all injuries are the result of overexertion and bodily reaction. This is a staggering number. To put it in perspective (for all those football fans out there), the average NFL stadium holds 69,000 screaming fans. So, the number of people injured from overexertion could fill up over four football stadiums!

People have been trying to solve this problem for years, and ergonomics have been the most commonly accepted answer.

Merriam Webster’s dictionary defines ergonomics as “an applied science concerned with designing and arranging things people use so that the people and things interact most efficiently and safely.” So, it’s all about engineering the environment to the human being. By virtue of engineering the environment to the human being, we can engineer some of the risk out of it, thus reducing the opportunity of injury.

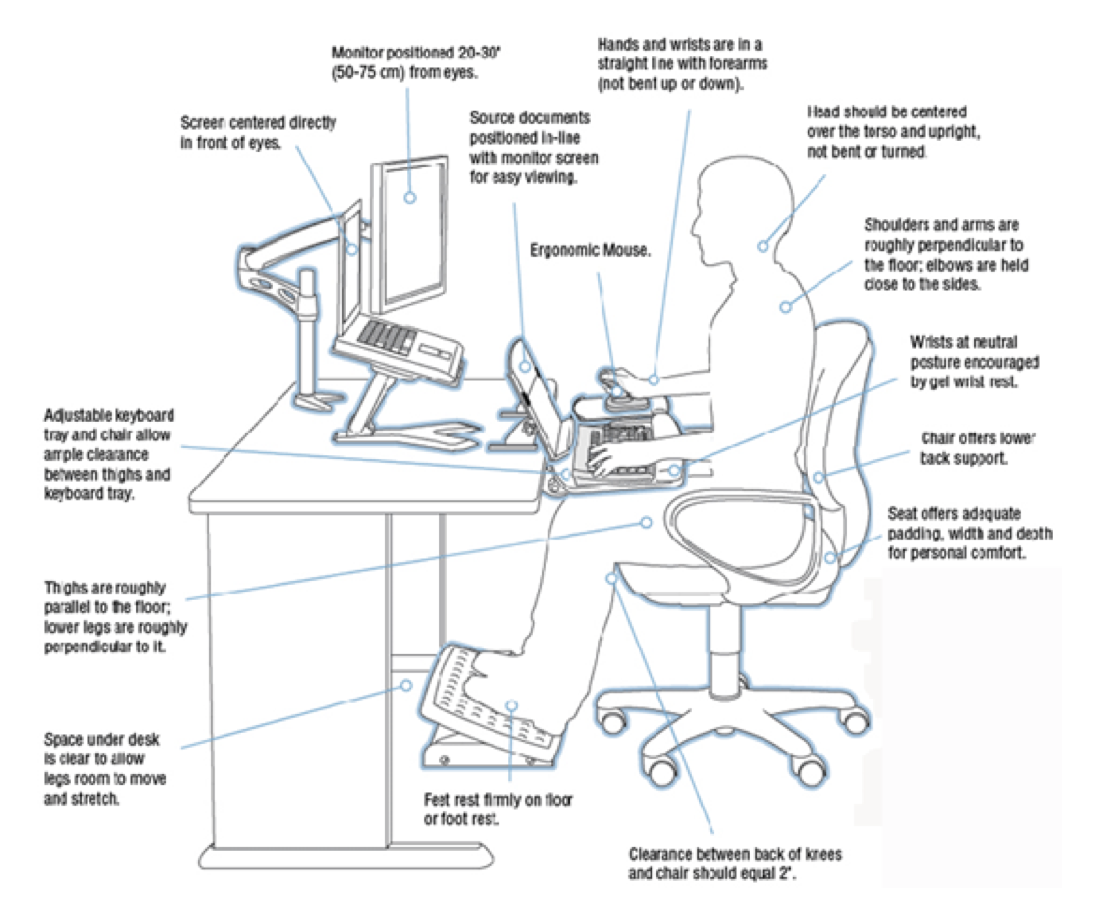

Let’s think about the office environment as an example. This is very applicable to people, like myself, who sit at a desk in front of a computer for most of the time these days. In the office, which is a very controlled environment, there are many opportunities for engineering (ergonomics) to greatly reduce the risk of injury. I can get a fancy ergonomic chair. I can put a pad under my wrists. I can raise my monitor up to eye level. I can get a footrest. I can even get a standing desk. The list goes on and on and eventually I may end up looking like I’m in a flight simulator.

But it works.

OSHA performed a study published in 2002 that showed, all else being equal, ergonomically engineering the environment eliminated 26 percent of “ergonomic related” injuries, resulting in days away from work over a 10-year period. I’ll take it!

However, what do we do about the other 64 percent of “ergonomic related” injuries? If I look at the definition of ergonomics, it doesn’t tell me anything about how the human will actually interact with that engineering.

Let’s go back to me at my desk. I can buy my $800 ergonomic chair, but if I slouch over and sit in a poor position all day long, then it is not going to do me any good. I am going to end up with back and neck pain and then potentially a MSI.

I need to use my body to correctly interact with the engineering to get any benefit from it.

Now let’s take a delivery driver using a box truck with no lift gate as an example. We can add engineering, such as handles and steps, ramps, a hand cart, and more to help make the job easier and reduce the risk.

However, even ergonomic engineering can create added opportunity for injury, if not used properly or even when putting it in place (ooh, a shoulder injury in the making).

Many times, it just comes down to the team member and the task (or in this case, the team member and a keg). No engineering, short of getting a robot to do the job, can completely eliminate the risk.

Millions of front-line workers who do more than sit at a desk all day long, such as delivery drivers, warehouse workers, linemen, nurses, or firefighters (just to name a few), come across an infinite number of situations each and every day. Ergonomics simply can’t be applied to this multitude of tasks, environments and situations.

If we can’t engineer the risk out of the environment, we need to focus on the human being. By focusing on the human, how they use their body to move through space and interact with their environments, we’re able to put them in stronger, more stable positions. This prepares them for any situation, and employers do not rely on ergonomic tools to prevent injury. Employers are simply reevaluating situations altogether.

We aren’t creating supermen or superwomen, but we are able to reduce the risk of injury in the 1) known environments where we have been able to implement ergonomics by interacting with that engineering correctly, 2) in the known environments where we have not yet been able to implement ergonomics, and 3) in the circumstances and environments we have not yet encountered.

Movement matters, and ergonomics is not the whole answer.

Benjamin Kanner is the co-founder and CEO of Worklete, which he built based off a consulting practice his father started and ran for 30 years. You could say Ben was born for this business. Prior to Worklete, Ben co-founded and served as the COO for ChouxBox, a software solutions provider for the hospitality industry. Early in his career, Ben held various financial positions at Deutsche Bank Rabobank and Contour Venture Partners. To learn more about Worklete’s injury prevention program, visit worklete.com.