Page 2 of 3

We Must Change the Statistics of Confined Space Injuries and Fatalities

They say some things never change. When it comes to permit required confined space entry (PRCS) injuries and fatalities, this old adage seems to hold true. Statistics, old or new, show we have not improved mitigating, or eliminating, the risk of confined space injuries and fatalities.

Statistically Speaking

About 2.1 million workers enter permit confined spaces annually. According to the National Institute for Occupational Safety and Health (NIOSH), approximately 60 percent of confined-space fatalities are rescuers, and the Occupational Safety and Health Administration reported that when multiple deaths occur during a rescue, the majority of the victims are "would-be" rescuers.

Here are some findings of the NIOSH investigations of confined space incidents:

- 85% of the time a SUPERVISOR was present.

- 29% of the dead were SUPERVISORS.

- 31% had WRITTEN Confined Space Entry PROCEDURES.

- 0% used the WRITTEN PROCEDURES.

- 15% had Confined Space TRAINING.

- 0% had a RESCUE PLAN.

- 60% of "WOULD-BE" RESCUERS died.

- 95% were AUTHORIZED by supervision.

- 0% of the spaces were TESTED prior to entry.

- 0% were VENTILATED.

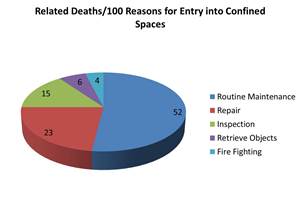

Out of 100 deaths that were investigated, the main reasons the workers entered the confined space were to perform their work functions of routine maintenance, repairs, and inspections of the confined space.

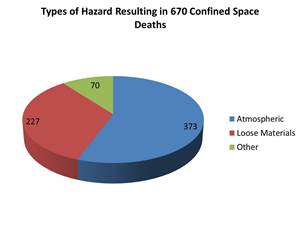

Out of 670 confined space deaths, the most common types of hazards were atmospheric hazards and loose materials.

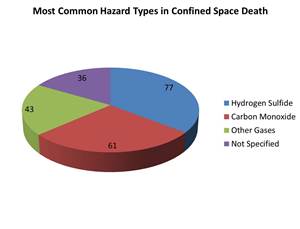

And out of 217 confined space deaths that were investigated, the two most common types of gases in confined spaces, hydrogen sulfide and carbon monoxide, were the causes found.

While these NIOSH statistics may slightly differ over the years, the reality is that the hazards of confined space entry are the same. Too many workers today are still seriously injured or dying in permit required confined spaces.

So the real question is to ask, "Why aren't we eliminating or mitigating these risks?" Sadly, some things never change or never change enough because there is no continuous focus from the employers on realistically preparing, supervising, and protecting our workers before entry.

Time for a Reality Check

For more than 15 years, I have been training industrial and manufacturing workers on permit required confined space entry and rescue. The training required for entering a confined space includes a Supervisor, Entrant, Attendant, and Rescue Team.

The reality is that in my career of emergency response services for industrial and manufacturing facilities, I far too often see so many facilities that do not take permit required confined space entry preparation seriously. Their confined space entry and rescue training is inadequate, usually a short video and most often not retained, or utilization of a third-party trainer who doesn't specialize in confined space training; thus, they’re receiving poor-quality training.

They do not have the proper equipment for confined space retrieval or rescue. They do not have the proper personal protective equipment, or their equipment has not been taken care of and is not safe to use. Or worse yet, they have no equipment at all. Their workers are not trained on the hazards associated with permit required confined spaces. They have no rescue plan or rescue team in place. They opt to call 911 (not an option). They decide they will perform only non-entry rescues, which are rarely effective when you need to rescue an unconscious victim. (Non-entry rescue only as a plan is an entire topic for another article later!)

The reality is workers and rescuers are still dying or getting seriously injured in confined spaces. The reality is permit required confined spaces are still the leading cause of multiple fatalities in the workplace. The reality is that OSHA regulations mandate employers to provide training, equipment, and proficient rescue services for permit required spaces.

For permit required confined space, OSHA requires employers to identify hazards in confined spaces, test the air prior to entry and during entry, keep the space ventilated, have the proper safety equipment for entry and exit and rescue, and have procedures for summoning proficiently trained rescue teams who can respond in a timely manner.

So how do we change the statistics of confined space injuries and fatalities? Every facility needs to conduct a reality check. A well-designed and properly executed rescue plan is a must (not an option). Investigate their permit required confined space procedures thoroughly. Make changes. Identify and comply with OSHA regulations. Make changes. Inventory their equipment—replace, buy, repair. Make changes. Assign and train their workers and rescuers. Make changes.

The reality is, things must change, and it is the employers who are responsible for protecting their workers.

Time for Things to Change

Why am I so passionate about permit required confined space safety? I have witnessed the "best in class" facilities that made the right changes, and continue to make changes, to their permit required confined space entry procedures. Unfortunately, I also have visited the ones who did not, have not. The reality is, I have conducted permit required confined space entry and rescue training at facilities after a fatality(s). I have seen the faces of the workers who are grieving the loss of their co-worker(s). I have heard how distraught they are when they find out their employer didn't do what was required by OSHA.

The resources are out there for all employers to mitigate, or eliminate, the risks of injury or a fatality(s) when their workers are entering confined spaces as a part of their work function to perform maintenance, repairs or inspections, or other work. There is no excuse to not change the statistics. And if your facility does not have the internal resources necessary to investigate, evaluate, plan, and, most importantly, make changes, find a highly qualified and reputable third-party company that can assist in written procedures, training, and identifying the proper equipment.

Protecting workers is the law and, more importantly, it's the right thing to do to protect your workers. Your financial investment in a good permit confined space program, training, and equipment is minimal compared to the OSHA citations and the lawsuits that may be filed due to the death of a worker in a confined space. And the cost of keeping on with the old adage, some things never change, is even much higher. The reality is the loss of a worker(s) to a confined space incident is not an option. The reality is with proper training and equipment, the loss of workers working in and around permit required confined spaces can be prevented.

It's time for the NIOSH and OSHA statistics to change.

This article originally appeared in the August 2018 issue of Occupational Health & Safety.