Five Questions Every Safety Manager Should Ask When Choosing High-Vis Apparel

Choosing the right high-visibility clothing for the job per the ANSI standard is a good first step to preventing injuries on a work site. But workers must use the garments and care for them.

- By Audrey Ronis-Tobin

- Jul 01, 2018

There's more to high-visibility safety apparel than meets the eye. By definition, it's clothing with highly reflective properties that help workers stay visible against any background and in any lighting conditions, even at night. The ability to be seen is critical for worker safety, especially for those working around moving vehicles and equipment—from construction sites to roadways, and in warehouses.

But not all high-visibility garments are the same, and requirements vary across the wide range of uses and environments workers face every day. The following is a handy primer on selecting the right high-visibility products for your organization and job functions.

WHO wears high-visibility apparel?

Many workers are either required or choose to wear high-visibility apparel to reduce the incidence of on-the-job accidents and injuries. These include highway and railway crews, airport workers, loggers, hunters, commercial fishermen, construction tradespeople, trash and recycling collectors, landscaping professionals, warehouse workers, first responders, and many others.

Many workers are either required or choose to wear high-visibility apparel to reduce the incidence of on-the-job accidents and injuries. These include highway and railway crews, airport workers, loggers, hunters, commercial fishermen, construction tradespeople, trash and recycling collectors, landscaping professionals, warehouse workers, first responders, and many others.

The key is to choose the high-visibility option that provides the greatest degree of contrast between a worker's body and his or her surroundings. Hunting laws in many states, for instance, require hunters to wear blaze orange garments to distinguish them from game animals. When working in or around heavy foliage, orange or red apparel options may be preferable. The color of work zone equipment also can influence the best choice of fluorescent background materials.

WHEN is high-visibility apparel required?

The federal mandate that requires select workers to wear high-visibility apparel can be found in the Manual on Uniform Traffic Control Devices 2009 (MUTCD 2009), which is translated and enforced by each state. The Occupational Safety and Health Administration also has developed an interpretation statement regarding MUCTD, intended to clarify when high-visibility apparel is required. It can be found at: https://www.osha.gov/laws-regs/standardinterpretations/2009-08-05.

OSHA has essentially interpreted MUTCD 2009 to require employees working on highway and road construction work zones to wear high-visibility garments when they work as flaggers or when they are exposed to public vehicle traffic and/or construction equipment.

Other classes of occupational workers, such as trash collectors or commercial construction pros, are not required to wear high-visibility safety apparel by federal law. But the American National Standards Institute (ANSI) has established high-visibility standards to help employers and safety managers across these occupations choose high-visibility clothing that is appropriate for the safety of their workers.

WHAT are the basics of high-visibility apparel design?

The typical components of most high-visibility garments include:

- Fluorescent materials that use special pigments that are brighter than other colors and enhance daytime visibility, especially in low light such as cloud cover, dusk, and dawn. Fluorescent lime, orange, and red are the three approved background color options for high-visibility clothing.

- Retroreflective tape that reflects light in the direction of its source, such as a vehicle’s headlights, thereby illuminating a worker in low light or at night.

- Combined performance materials, such as tape that is retroreflective and also fluorescent.

WHAT are Performance Class and Garment Type designations, and how do they impact product selection?

When it comes to high-visibility clothing, there are many options. With different color-ways, reflective tape patterns, sleeve lengths, it can be tricky choosing the right apparel for the job. The ANSI/ISEA 107-2015 standard, which is voluntary, sets forth what is an approved fluorescent material and reflective tape, as well as what level of brightness and coverage are recommended for various kinds of work environments.

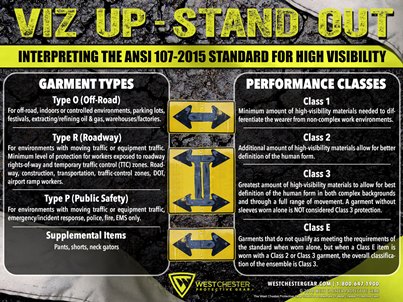

ANSI 107 sets forth four performance classes (Class 1, 2, 3, and E) and three garment types (Type O, P, and R) of high-visibility apparel.

Performance Class 1 garments offer the minimum amount of high-visibility materials needed to differentiate the wearer from non-complex work environments, such as in warehouses. On the other side of the spectrum, Class 3 apparel offers the greatest amount of high-visibility materials to allow for the best definition of the human form in both complex backgrounds and through a full range of movement. Class 3 performance clothing is typically worn by road or maintenance workers in highway work zones. Class 2 garments fall between the other two in the amount of background and retroreflective materials.

In addition, Class E describes pants or bibs. When worn with Class 2 or Class 3 vests, shirts, etc., the total ensemble of pants/bibs and tops is classified as Class 2 or Class 3.

In addition to the performance classes, the ANSI standard also establishes three garment types: Type O for work that takes place off-road or in controlled environments, Type R intended for roadways, and Type P intended for public safety workers. Performance class and garment type are co-dependent, which means that to qualify under the ANSI standard, the apparel must have both a class and a type (not just one or the other). The chart in this article provides some general guidelines that can help in choosing the right clothing.

HOW can workers get the most out of their high-visibility apparel?

Choosing the right high-visibility clothing for the job per the ANSI standard is a good first step to preventing injuries on a work site. But workers must use the garments and care for them. Manufacturers typically offer a variety of options—within the various ANSI performance classes and garment types—to cater to user preferences and improve the likelihood that garments get worn.

Snow or rain or heat or gloom of night

The environmental conditions that workers face on a daily basis should be a major consideration in clothing selection so as to maximize use. Vests and short-sleeve shirts can keep workers cool in the heat, while long-sleeve shirts can provide additional warmth in cooler conditions and outerwear and rainwear can block out cold, wind, and rain.

Some features that workers appreciate include:

- Wicking material to improve dryness against the skin

- Wider neck openings for comfort and breathability

- Drawstrings or adjustable straps at the waist for a custom fit

- Breaks in reflective tape at side seams to allow for extra stretch

- Mesh for breathability

- D-ring slot for connectivity to a harness for fall protection

- Fitted styles for women or smaller body shapes

- Hook & loop or zippered closure options

Pick a pocket or two—or ten

Convenience is also critical to getting worker "buy-in" to wear high-visibility apparel. Your supplier should offer a range of standard storage configurations and options (as well as customization capability) encompassing:

- Pockets—standard, oversized, interior and exterior, with or without closures

- Mic tabs on shoulders

- Phone pockets with sealable flaps in sizes to store smaller cell phones to tablet-sized electronics

- Pen slots, interior or on chest

A solution, whatever the style and added safety needs

Some jobs, such as surveying, call for specific styles of high-visibility apparel. If you are specifying products for surveyors, a selection of safety vests that are optimized with mic tabs, pen slots, and other features designed especially for them will be welcome.

For workers in especially hazardous environments, enhanced safety features are also something to consider. Five-point breakaway clothing styles, for instance, are critical for those working in close proximity to moving vehicles or equipment. Self-extinguishing garments made with treated fabric material tested to meet ASTM or NFPA standards may be appropriate for workers exposed to flammable materials as part of their job.

A Note on Service Life Expectancy

All high-visibility products have a limited lifetime that varies with use. It's the responsibility of safety professionals, employers, and the wearer to periodically evaluate each garment's required visibility and replace it when it fades, tears, or is overly dirty. If the apparel isn’t visible at 1,000 feet—day or night—it's best to make a change.

Although a garment's lifespan will depend on the type of work, if worn on a daily basis, the useful life is probably around six months. Clothing not worn on a daily basis is expected to have a useful life of up to one year.

This article originally appeared in the July 2018 issue of Occupational Health & Safety.