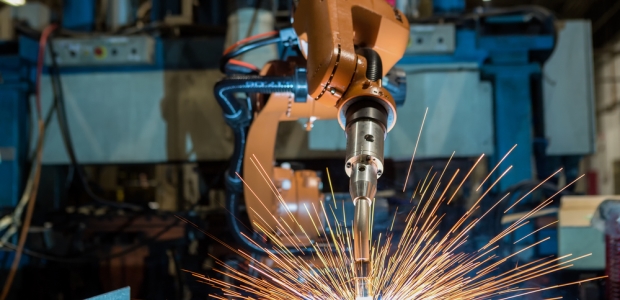

NIOSH Creates Robotics Research Center

NIOSH researchers have identified 61 robot-related workplace deaths between 1992 and 2015. "We suspect fatalities will increase over time because of the growing number of industrial robots being used by companies in the U.S., and from the introduction of collaborative and co-existing robots, powered exoskeletons, and autonomous vehicles into the work environment," said Dawn Castillo, MPH, director of NIOSH's Division of Safety Research and the center's program manager.

NIOSH announced Oct. 16 that it is launching a Center for Occupational Robotics Research to assess potential benefits and risks of robot workers and develop guidance for safe interactions between humans and robots.

Increasing numbers of robots are entering the 21st century workplace, yet the benefits and potential risks of robots in the workplace aren't fully known, according to NIOSH, hence the decision to create the new center to assess the benefits and risks and to develop guidance for safe interactions between people and robots. Its first formal partnership commenced on Oct. 5, 2017, when representatives of OSHA, NIOSH, and the Robotic Industries Association signed an alliance to work together to enhance OSHA's and NIOSH's technical expertise, improve awareness of workplace hazards associated with traditional industrial robots and the emerging technology of human-robot collaboration installations and systems, and help identify needed research to reduce workplace hazards.

"Robots working collaboratively with humans present a new workplace risk profile that is not yet well understood," NIOSH Director John Howard, M.D., said. "Not only is this a new field for safety and health professionals; little government guidance or policy exists regarding the safe integration of robots into the workplace. NIOSH's Center for Occupational Robotics Research will provide the scientific leadership needed to ensure human workers are protected."

According to the agency's announcement, NIOSH researchers have identified 61 robot-related workplace deaths between 1992 and 2015. It said the center will continue to monitor trends in injuries associated with both traditional and emerging robotics technologies.

"We suspect fatalities will increase over time because of the growing number of industrial robots being used by companies in the U.S., and from the introduction of collaborative and co-existing robots, powered exoskeletons, and autonomous vehicles into the work environment," said Dawn Castillo, MPH, director of NIOSH's Division of Safety Research and the center's program manager. "NIOSH has a history of robotics research and, through the Center for Occupational Robotics Research, we are poised to proactively address the safety of today's and tomorrow's workers who use, wear, or work near robots."

NIOSH said it will work in partnership with partners in academia, industry, and government to establish risk profiles of robotic workplaces, identify research needs, and conduct research to improve the safety, health, and wellbeing of humans working with robots and robotic technologies and support the development and adoption of consensus safety standards.

Visit this NIOSH website for more information on robotics and about the center.