Fatality Investigation: 22-Year-Old Construction Laborer Killed in Trench Collapse

The Kentucky Fatality Assessment and Control Evaluation (FACE) program investigates fatalities and makes recommendations for preventing future similar injuries.

- By De Anna McIntosh

- Jul 01, 2017

Despite the variety of trench safety practices and protective devices available on the market, excavation and trenching remain among the most hazardous operations on a construction site. As defined by OSHA, a trench is an underground excavation that is deeper than it is wide. Variability in soil types and other environmental factors make working in these crevices a unique safety challenge, and many workers underestimate the sheer weight of only a small amount of collapsed dirt. Shortcuts should never be taken for sake of project expediency.

A recent fatality investigation by Kentucky FACE, a NIOSH-supported occupational fatality research program, details the preventable death of a young father in a trench collapse.

A local highway construction company (in business since 1992) had been hired as a subcontractor to install an 18-inch-diameter storm sewer drainage pipe alongside a two-lane road. On the morning of the incident, the superintendent of the crew of 10 held a pre-work meeting to discuss the work to be done that day. The meeting included general safety awareness but did not specifically address proper trench safety and trench collapse hazards. All employees had received previous safety training with the company. The crew superintendent assigned the victim to assist the excavator operator in taking trench grade measurements. No thorough inspection was conducted prior to beginning work, and no soil testing was carried out of the area where the trench work was to take place. Additionally, a trench box and/or shoring supports were not on site.

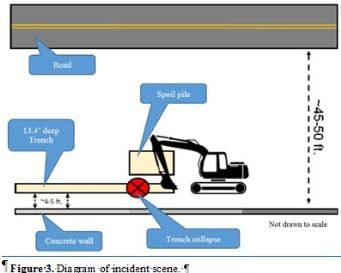

The excavator operator stated he was benching the street side of the trench, similar to a previous job they had performed in the past. Photos of the scene suggest partial benching of the top of the trench (see figure 1C), but the trench was too close to an adjacent concrete wall (depicted in figure 1) to be properly benched. The excavator operator also stated that the superintendent witnessed the victim enter and exit the unprotected trench multiple times that morning.

At approximately 9:30 a.m., the construction worker jumped into the trench to take grade measurements. The excavator operator observed the collapsing of the concrete wall facing side of the trench and yelled to the construction worker to jump out. The construction worker did not have adequate time to escape, and the trench collapsed and buried him under dirt and gravel. Nearby employees jumped into the collapsing trench and tried to rescue the victim by digging. Emergency Medical Services were called and arrived at 9:47 a.m. A trench collapse special response unit from the fire department arrived and recovered the construction worker at 10:52 a.m., unresponsive. Unfortunately, rescue efforts took too long, and the coroner pronounced the victim dead at the scene at 10:52 a.m.

Lack of Trench Protective System

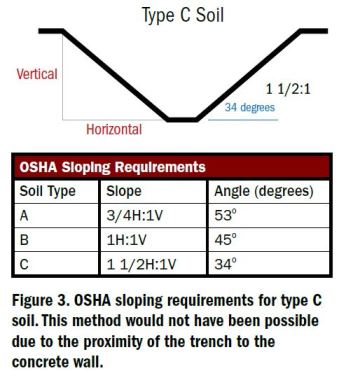

Performance of a soil test and an adequate trench protective system could have prevented this incident. OSHA requires that all workers in trenches 5 feet or more in depth be protected by sloping, shoring, or the use of shields. Since the soil was a mixture of class B and C soils, the soil should have been classified as class C soil. Trench excavation with class C soil requires sloping at 1½ H:1V (or 34°), meaning that the soil needed to be cut back 1.5 feet for every 1 foot of depth (Figure 3). Given the proximity of the trench to the concrete wall, it was impossible to achieve the necessary slope on both sides of the trench. Since the concrete wall made conventional sloping techniques impossible, a trench box or shoring system should have been installed prior to allowing entry into the trench.

Performance of a soil test and an adequate trench protective system could have prevented this incident. OSHA requires that all workers in trenches 5 feet or more in depth be protected by sloping, shoring, or the use of shields. Since the soil was a mixture of class B and C soils, the soil should have been classified as class C soil. Trench excavation with class C soil requires sloping at 1½ H:1V (or 34°), meaning that the soil needed to be cut back 1.5 feet for every 1 foot of depth (Figure 3). Given the proximity of the trench to the concrete wall, it was impossible to achieve the necessary slope on both sides of the trench. Since the concrete wall made conventional sloping techniques impossible, a trench box or shoring system should have been installed prior to allowing entry into the trench.

The excavation operator commented that he was to bench the road-facing side of the trench. However, OSHA requires that type C soil be sloped and never benched. Furthermore, sloping and benching techniques must be applied to both sides of the trench to be effective. The side of the trench facing the concrete wall was the side that was most unstable and suffered the fatal collapse.

The soil along the concrete wall facing the side of the trench was a mixture of class B and class C soil, along with #57 gravel backfilled along the wall foundation. The soil surrounding the base of the concrete wall had previously been disturbed during the wall's construction. The spoil pile was placed on the road-facing side of the trench at the required 2 foot minimum distance, however, this was still unsafe due to the pile's size and the lack of a trench protection system.

Recommendations and Discussion

Alternative methods for measuring trench grade and depth (that do not require an employee to enter the trench) should be utilized, including measuring rulers or poles and excavator depth monitors. Excavator depth monitors allow the excavator operator to monitor the depth and grade from the safety of the operator's cab. The monitors display highly accurate calculations and often eliminate the need for an operator assistant to check trench grade and/or depth. Modern excavator depth monitors are wireless, require minimal installation, and can be moved between machines.

Employers and site managers should ensure employees working in trenches 5 feet or more in depth are protected from cave-in by adequate protection systems appropriate for the conditions in the trench, including sloping or benching techniques, shoring, or shields (trench boxes).1 Sloping involves making sure that the soil is at an angle to prevent the soil from caving into the trench. In this particular incident, sloping was not a viable option due to the proximity of the trench to the adjacent concrete wall. When sloping methods are not feasible, trench shields or aluminum hydraulic shoring systems should be used. In addition to the use of correct protective systems, the spoil pile should also be at least 2 feet from the edge of the trench.

When installing miles of pipeline or cable, the amount of soil that must be moved along with the associated cost of excavator fuel, operator time, backfill, compaction, etc., can make sloping inefficient and time consuming in regard to project deadlines. Rather than foregoing the use of a protective system altogether, it is strongly recommended that employers at least require trench shields or aluminum hydraulic shoring systems, both of which are OSHA-approved protective systems that can be rented, if needed. These protective systems can still adequately protect workers while increasing project expediency and efficiency.

Employers should ensure a competent person conducts soil testing and daily inspections of the excavations, adjacent areas, and protective systems. A competent person is defined by OSHA 1926.650(b) as "a person capable of identifying existing and predictable hazards in the surroundings, or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate the hazards."2 Inspections should occur throughout the day and as conditions change. The competent person on the job site was the superintendent who did not perform a soil test or inspection of the work area prior to allowing work to begin. This was important because the stability of the soil was affected by seven straight days of rain prior to the fatal incident. An adequate soil test should have taken into account that the soil near the concrete wall's foundation had been previously disturbed, increasing the likelihood of a trench collapse and increasing the need for a required trench protection system.3 The employer had a digital tool to identify soil classification, however, the tool was not used on the day of the incident.

Daily toolbox talks should be conducted that emphasize safety topics related to the upcoming job tasks prior to allowing work to begin on the job site. Pre-work meetings were held before the start of the workday. During the meetings, general safety hazards were discussed; trench safety was not discussed.

Employers should intervene when unsafe acts on the job site are witnessed. During the investigation and interview process it was discovered that the victim had climbed into and out of the unprotected trench several times that morning. Superintendents and other site management personnel should intervene when they witness unsafe job practices.

Safe means of ingress and egress should be provided in all excavations prior to entry. The fatality investigation found no ladder or other safe means of ingress or egress in the trench. OSHA regulations require safe egress and ingress in a trench measuring greater than 4 feet in depth.3 Acceptable means of ingress and egress include ladders, steps, and ramps.

Disclaimer & Acknowledgement

This publication does not represent final determinations regarding the nature of the incident, cause of the injury, or fault of employer, employee, or any party involved. Kentucky FACE is grant funded by grant 2U60OH008483-12 from the National Institute for Occupational Safety and Health and operates from the Kentucky Injury Prevention and Research Center (KIPRC) at the University of Kentucky. KIPRC is a bona fide agent for the Kentucky Department for Public Health, http://www.mc.uky.edu/kiprc/.

References

1. Specific Excavation Requirements. 29 CFR 1926.651(c)(2). Occupational Safety and Health Administration. https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id=10775

2. 29 CFR 1926 OSHA Standards for the Construction Industry, Second Edition. Subpart P Excavations. 2009. Print.

3. Soil Classification. 29 CFR 1926 Subpart P App A(c). Occupational Safety and Health Administration. https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id=10931

This article originally appeared in the July 2017 issue of Occupational Health & Safety.