How to Choose Gloves to Protect Against Arc Flash

You don't want to wear gloves that will burn, catch fire or not protect from heat. Beyond sustained injuries, ignoring the need for proper electrical PPE can result in huge fines.

- By Amanda Green

- Feb 01, 2017

There are a lot of misconceptions about arc flash, starting with what it actually is. It is not a flash of light or an arc of fire. It is related to but not the same as electric shock, and there is not usually direct contact with electricity. Yet arc flash is deadly serious, and there are more than 30,000 incidents that result in 400 fatalities every year. So how can you protect your hands from this deadly killer?

Can Arc Flash Be Prevented?

Yes. Let's start by exploring what arc flash is. Arc flash is an electrical current that jumps from the desired path and travels through the air from one conductor to another. It incorporates both radiant and convective heat and can reach temperatures of up to 35,000° F. Imagine a bolt of lightning veering off course. It has the potential to ignite clothing and burn workers. Anyone in the path of the electrical discharge or in the vicinity can be severely injured or even killed.

Arc flashes can occur around high-voltage or current machinery for several different reasons, including:

- Incorrect wire gauge

- System overload

- Worn-through or thinning insulation

- Corroded contacts

- Cleaning with flammables

- Dropped, misplaced, or improperly used tools

- Accidental human contact due to inappropriate gloves or other PPE

- Improper or incomplete installation of equipment

The most obvious and best way to prevent an arc flash is to work on de-energized equipment. If there is no current flowing through a device, there will be no arc flash. Sometimes, however, it is necessary to work on energized equipment or on equipment whose status is unknown. In these circumstances, it is important to work with your safety specialist to find the proper hand protection for working with energized circuits.

1. Prevent ignition by wearing gloves that will not ignite.

While arc flash injuries can be to the face, hand, or body, hands are normally first to catch fire. Therefore you don't want to wear gloves that will burn, catch fire, or not protect from heat. Beyond sustained injuries, ignoring the need for proper electrical PPE can result in huge fines.

Rubber insulating gloves are traditional for working with arc flash hazards. Rubber insulating gloves can be bulky or difficult to work in, so lighter-weight arc flash and electrical gloves are coming into the market.

When do you need to wear rubber-insulating gloves, and when can you simply wear arc flash-rated gloves without rubber-insulating gloves underneath? According to the NFPA 70E and the CSA Z472 standards, all types of work with shock exposures of greater than 50V require the use of rubber insulating gloves.

Most non-rubber arc flash gloves are either leather or coated, and they are all FR protective. The materials they are made from can be either inherently FR (like aramid, leather, wool, glass, and coated nylon) or treated (as in with Pyrovatix, Proban, or Indura).

2. Wear gloves with sufficient protection.

Protection must be adequate for the specific threat (level of exposure) presented by the equipment that you are working with. The arc rating of the machinery you are working on should be written on the electrical panel. If it isn’t, check the manufacturer's specifications. To choose the best glove for a job, you need to understand Hazard Risk Category (HRC) and Arc Thermal Protective Value (ATPV).

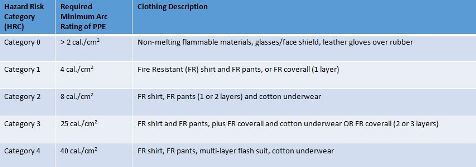

HRC is the safety standard that shows the minimum amount of PPE protection a worker needs based upon the potential exposure to a hazard he or she might experience. HRC categories range from 0 to 4, with 4 being the highest risk.

The other important number that is critical in choosing the right PPE is Arc Thermal Protective Value (ATPV). ATPV is the incident energy level (measured in cal./cm2) that would cause a second-degree burn.

The HRC and ATPV are determined through a flash hazard analysis that studies all the electrical circuits in the device capable of being energized and determines how much energy would be released in case of an arc flash. Once you identify the potential exposure of your task, you can then find the ATPV for that task. The ATPV leads you to the appropriate HRC level. (See the chart below.) ASTM F1506 is the standard that determines the HRC of a glove. ASTM P S58 is the standard that determines ATPV.

With more arc flash gloves available today, you have even more options to choose from—seamless knit gloves that are more dexterous than traditional rubber, coated gloves with enhanced grip, gloves with FR-treated TPRs on the back of the hand.

As long as you understand your critical numbers—HRC and ATPV for your task at hand—and choose the right level of protection for the job, arc flash gloves are more comfortable and protective than ever. Most important, you should always work with your safety specialist to make sure that you wear the appropriate PPE for your job.

This article originally appeared in the February 2017 issue of Occupational Health & Safety.