GHS Becomes Mandatory in Australia on Jan. 1

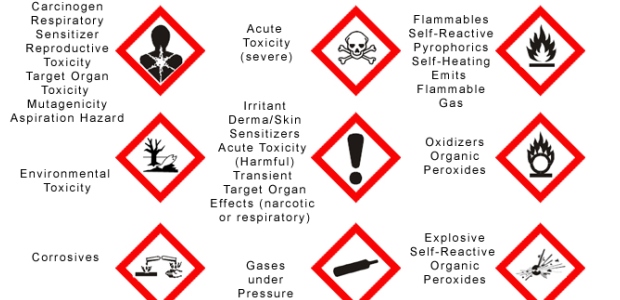

GHS was introduced in Australia in January 2012 with a five-year transition period to give chemical manufacturers and importers enough time to implement the necessary changes. It applies to chemicals with physical hazards, health hazards, and environmental hazards.

GHS, the Globally Harmonized System for the Classification and Labeling of Chemicals, will be mandatory in Australia beginning on Jan. 1, 2017, Netsight's Janine Nicholson pointed out in a Dec. 19 post on the company's blog. Netsight is an Australian-based vendor of EHS solutions, including its flagship product, myosh.

GHS was introduced in Australia in January 2012 with a five-year transition period to give chemical manufacturers and importers enough time to implement the necessary changes, Nicholson wrote, adding that GHS applies to chemicals with physical hazards (e.g., flammable liquids), health hazards (e.g., carcinogens), and environmental hazards (e.g., aquatic toxicity).

"Safe Work Australia CEO Michelle Baxter has recently confirmed that members have agreed to an amendment on the GHS Rollout. All chemicals manufactured or imported BEFORE 1st January, 2017 can now continue to be supplied without having to meet the labelling requirements of the model Work Health and Safety Regulations," Nicholson added. "Worldwide, countries have registers or inventories for classifying and controlling chemicals. *The European Union has the REACH initiative which controls chemicals in the European market, The USA has TSCA and Canada has CEPA requirements. In Australia there is AICS, China has the IECSC and similarly many other countries including Japan, India, Switzerland, South Africa etc. all have regulations which include duties to manage the risks to health and safety associated with using, handling, generating and storing hazardous chemicals at a workplace. The duties generally include: ensuring that a register of hazardous chemicals is prepared and kept up-to-date so that people can easily find information about chemicals stored, handled or used at the workplace, as well as identifying risk of physical or chemical reaction of hazardous chemicals. Registers should be readily accessible to workers involved in using, handling or storing hazardous chemicals and to anyone else who is likely to be affected by a hazardous chemical at the workplace. They must be updated as new hazardous chemicals are introduced to the workplace or when the use of a particular hazardous chemical is discontinued."