Four Steps to GHS Compliance

The GHS compliance date of Dec. 1, 2015, has passed. Are you in compliance?

- By Nick Recht

- Jan 01, 2016

In the chemical industry, safety is of the utmost importance. OSHA estimates that more than 43 million employees in the United States could be exposed to hazardous chemicals.1 Implementing appropriate work practices and exposure guidelines can reduce health and safety risks. This involves creating accurate and secure labels for chemical materials, which allows workers to quickly and easily understand information about the hazards to which they are exposed.

OSHA has made modifications to the Hazard Communication Standard (HCS) final rule to adopt the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) in effort to improve the health and safety of employees working with hazardous chemicals. As of June 1, 2015, all chemical manufacturers, importers, and employers must ensure all labels and safety data sheets (SDSs) comply with the modified provisions.1

The next GHS deadline was Dec. 1, 2015, when distributors could no longer ship products labeled by manufacturers under the old system. Another deadline is approaching: There is a June 1, 2016, deadline for all employers to update their alternative workplace labeling and HazCom program as necessary.

OSHA recently released the top 10 most frequently cited violations of OSHA standards in fiscal 2014 for all companies and industries, and Standard 1910.1200, Hazard Communication (HazCom), came in second with 6,156 violations.2 This is due to the fact that HazCom violations occur across many industries and are easy for OSHA inspectors to observe, in relation to hazardous materials not having labels or Safety Data Sheets (SDSs).

HazCom-related citations for all industries in 2014 amounted to penalties of $3,296,163.3 OSHA's penalty policy states that the maximum penalty OSHA can assess for each serious violation is $7,000, and $70,000 for a repeated or willful violation.4

With the next compliance date now in your rear-view mirror, now is the time to move from learning about the regulation to taking action and implementing key components to meet the requirements. Take these four steps to prepare your business for GHS compliance:

1. Learn about what has changed in the final rule.

The major changes to the HCS include:

- Labels: Chemical manufacturers and importers must provide a label that includes a harmonized signal word, hazard statement, and pictogram for each hazard class and category.

- Safety Data Sheets: Formerly known as Material Safety Data Sheets (MSDSs), these are used to provide information about hazards used in workplace chemical management and to obtain advice on safety precautions. Now these must have a specified 16-section format, as defined in this OSHA brief5.

- Hazard Classification: The definitions of hazard now include specific criteria for classification of health and physical hazards, as well as classification of mixtures. This will ensure that evaluations of hazardous effects are consistent across manufacturers and that labels and SDSs are more accurate as a result1.

2. Train your employees.

The deadline to train current employees on the new label elements and SDS formats was Dec. 1, 2013.

1 However, as new employees are hired, it is mandatory to train them in the same way, as well as to provide training to all employees whenever a new health or physical hazard is introduced into the workplace. Training should focus on how to interpret new pictograms, how to read updated labels, and what the various hazard statements, signal words, and precautionary statements mean. Communicating these hazards is essential to meeting the requirements of OSHA and to ensuring workplace safety.

3. Replace current MSDSs with SDSs.

For GHS compliance, ensure that the SDSs you receive include new hazard information. An SDS must include the 16 required sections in the specified order and in a uniform format with headings, section numbers, and associated information. Under the new HCS, section two will now be the hazard(s) identification segment, including required label elements that incorporate pictograms and signal words, while section three will include the information/composition on ingredients. There are new physical, environmental, and health classifications that must be incorporated into section two of the SDS.

4. Choose the right labeling software to label chemicals with required GHS elements.

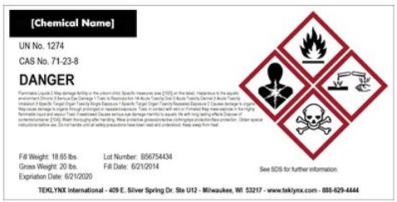

Chemical labels under GHS must include the following1:

- Hazard Statement: This describes the nature of the product's hazard with a phrase assigned to the hazard class.

- Pictogram: This is a graphic symbol that is intended to visually convey specific hazard information and must include a red border (or black border for workplace labels only).

- Signal Word: It must use either "Danger" (severe) or "Warning" (less severe).

- Product Identifier: This should be identical to the product identifier on the SDS.

- Supplier Identification: The name, telephone number, and address of the supplier or manufacturer must be listed.

- Precautionary Statement: This describes recommended measures to reduce or prevent adverse effects resulting from exposure.

Additionally, companies using National Fire Protection Association (NFPA) and Hazardous Materials Identification System (HMIS) rating systems for labeling workplace containers must numerically reverse the rating system under the new rule. Under GHS, the new ratings will be 1 (severe hazard) to 5 (minimal hazard).1 Employers using this method of workplace labeling must ensure employees are trained and fully aware of the hazards of the chemicals used.

When choosing label design software, be sure that the application allows for database integration so you can easily design and print GHS-compliant labels using information from a text file or database, including standardized data elements that meet GHS requirements. Having a label approval module that allows you to approve label designs using electronic signatures will help you meet industry mandates that require label security and traceability.

"With the extraordinarily high level of accuracy required for chemical labeling, choosing a labeling software that can efficiently meet those needs will be imperative to success," said David Kane, Label Design Product Manager of TEKLYNX Americas.

Below is a fictitious example of a GHS-compliant chemical label. The label contains a hazard statement, pictograms, signal word, product identifier, supplier identification, and the precautionary statement.

Figure 1: GHS-Compliant Chemical Label Example

OSHA estimates that the modified HCS will prevent 43 fatalities and 585 injuries and illnesses annually, valued at an estimated $250 million per year in savings related to the reduction of occupational risks.1

On top of this, it is expected that $475.2 million will be saved due to productivity improvements for health and safety managers and logistics personnel, $32.2 million during periodic updating of SDSs and labels, and $285.3 million from simplified hazard communication training. In addition to health and safety benefits, chemical manufacturers will need to produce fewer SDSs in future years, while employers will save time providing training to new employees as required by the existing OSHA HCS through the improved consistency of the labels and SDSs.

Implementing the final rule will also6:

- Improve the quality and consistency of hazard information in the workplace, making it safer for workers to do their jobs and easier for employers to stay competitive;

- Enhance worker comprehension of hazards, especially for low- and limited-literacy workers, as well as reduce confusion in the workplace, facilitate safety training, and result in safer handling and use of chemicals;

- Provide workers quicker and more efficient access to information on the safety data sheets;

- Result in cost savings to American businesses of more than $475 million in productivity improvements, fewer safety data sheet and label updates, and simpler new hazard communication training; and

- Reduce trade barriers by harmonizing with systems around the world.

As rules and regulations are finalized and another compliance date approaches, it is important to become familiar with the details of the GHS regulation and how to achieve compliance. "Chemical labeling will be vital for success of the GHS regulation and in improving workplace safety," Kane said. "It is best to get started now to implement a plan to reach GHS compliance by the mandated deadline and realize long-term benefits from having a safer workplace."

References

1. https://www.osha.gov/dsg/hazcom/hazcom-faq.html

2. https://www.osha.gov/Top_Ten_Standards.html

3. https://www.osha.gov/pls/imis/industryprofile.stand?p_esize=&p_stand=1910.1200&p_state=FEFederal&p_type=5

4. https://www.osha.gov/OSHA_FAQs.html

5. https://www.osha.gov/Publications/OSHA3514.html

6. https://www.osha.gov/dsg/hazcom/HCSFactsheet.html

This article originally appeared in the January 2016 issue of Occupational Health & Safety.