The Importance of Worker Knowledge in Slips, Trips, and Falls and the Utility of Virtual Reality-based Locomotion Research

Virtual reality interfaces have the potential to be useful in gait/locomotion research and training, particularly for scenarios focusing on the risks of slips and trips.

- By Carl Pankok, Jr., David B. Kaber

- Dec 01, 2015

Workers and employers are familiar with the dangers of driving, working with heavy machinery, and exposure to chemicals, but less attention has been given to the common workplace hazard of slips, trips, and falls. Injuries and fatalities associated with these hazards have seen a steady increase over the course of the past two decades. In 1992, there were fewer than 10,000 deaths resulting from slips, trips, and falls in the United States. That number has steadily increased to approximately 28,000 in 20121. According to the U.S. Bureau of Labor Statistics, 16 percent of all worker fatalities in 2013 resulted from slips, trips, and falls, amounting to 699 deaths2. These outcomes put a heavy burden on employers as well as the health care system in the United States.

In an effort to reduce the impact of slips, trips, and falls, the Occupational Safety and Health Administration suggests keeping walking areas dry and free of clutter, posting signage when floors are wet, and providing adequate lighting3. However, they do not mention worker training solutions that could promote sensitivity to dangerous surfaces, choosing proper footwear, or following procedures to avoid potentially hazardous slipping or tripping obstacles. Related to this, the vast majority of research on slip, trips and falls has focused on external factors such as walking surface conditions, footwear design, and worker negotiation of obstacles. Very little emphasis has been placed on worker internal factors, such as knowledge of hazards, comfort with the work environment, or complacency in following safe work practices.

A recent research article found that 70 percent of slip-and-fall injuries occurred to employees with as little as one year of experience in their current positions4, highlighting the potential problem of complacency among workers. Their results suggested that periodic employee training could reduce the number of injuries and fatalities associated with slips, trips, and falls.

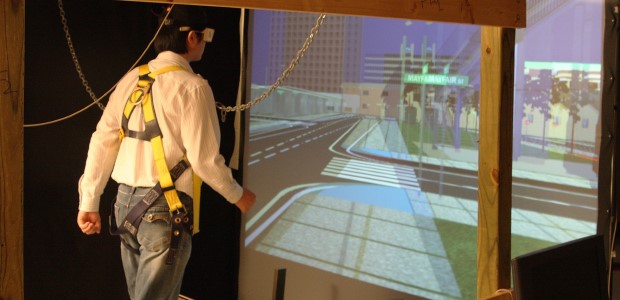

With this in mind, researchers at the North Carolina State University Edward P. Fitts Department of Industrial and Systems Engineering recently published results from an experiment assessing how internal factors, such as the fidelity of worker training and prior knowledge of a walking environment, affect walkers as they approach slip and trip hazards while multitasking. A virtual environment (VE) of a suburban town was projected on a screen in front of a treadmill while walkers wore light shutter glasses in order to provide the visual sensation of walking through a 3-D environment. As the participants walked through the environment, they encountered puddles and potholes in the sidewalk representing slips and trips, respectively. As their avatar encountered these virtual obstacles, an experimenter pulled a leash attached to the participant's ankles to simulate the forces of a slip or trip. The treadmill contained a force plate so that changes in each participant's gait could be measured as they approached the puddles and potholes.

To test the effects of walker internal factors associated with changes in gait, participants were split into three training groups and two multitasking groups. The training groups were labeled "low," "medium," and "high" and represented how closely the training paradigm replicated the actual experiment scenarios. The "high" training group was trained in a VE that was close to an exact replica of the experimental scenarios, whereas the "low" training group was trained in an environment that did not resemble the experimental scenarios. For the multitasking group, one group’s members were required to periodically report their positions in the VE and answer questions about their route, which had the purpose of imposing a high cognitive load on participants while they were negotiating the obstacles in their walking path. The other multitasking group's members were not required to report their positions or answer questions about their route. It was expected that participants who had the higher levels of training would be better able to adjust their gait patterns in advance of a slip or a trip, evidenced by the measurements from the force plate in the treadmill. Similar results were expected for the participants who were not required to report their positions or answer questions about their route.

Study Results

Results of the study suggested that the training regimens that more closely represented the experimental conditions led to increased knowledge of the walking situation, which, in turn, led to greater participant ability to adjust strides in advance of a slip or a trip and to prevent a fall. Similar to this, the results showed that as participants were exposed to more experimental trials (each participant was asked to walk through the scenario four times), they exhibited more proactive control over their gait, suggesting greater capability to avoid hazards. Multitasking conditions affected the results in line with expectations; participants who were exposed to higher cognitive load were worse at adjusting their strides to avoid slips and trips. Finally, results also revealed that participants tended to adjust their gait three to five steps from a hazard in order to avoid it.

Overall, the findings of this study show that there is a connection between a walker's internal model of the environment and situation, cognitive multitasking, and the ability to adjust gait to avoid a potential slip or trip. This connection is valuable for implementing solutions to prevent potential slips, trips, and falls. All participants in the experiment had no prior experience with the virtual reality environment or the sensation of the leashes tied to their ankles, yet they were able to quickly learn the environment and hazards to the point that they could adjust stride, foot posture, and forces to avoid the slips and trips. This emphasizes the importance of periodic training to update worker internal models of a work environment and its hazards in order to reduce the incidence of slips, trips, and falls. Regarding multitasking, jobs should be designed to minimize cognitively demanding tasks while workers are walking in areas that could pose slip and trip hazards. Finally, workplaces should be designed such that there is enough space for walkers to have three to five steps to adjust their gait before a potential hazard.

Virtual reality interfaces have the potential to be useful in gait/locomotion research and training, particularly for scenarios focusing on the risks of slips and trips. The technology has been underutilized, with many research paradigms involving lengthy walking surfaces and suspended harnesses that travel with the walker on an overhead track. A few force plates are used to measure ground reaction forces. Virtual reality setups have the advantage of being much more compact than these large apparatuses, as well as the ability to measure ground reaction forces for every step the walker takes (by using an instrumented treadmill), as opposed to the one or two that can be captured with a force plate placed in a long over-ground walking platform. Virtual reality also allows for the use of an infinite number of virtual walking scenarios, unlike physical lab setups.

Prior research has shown that treadmill gait can be comparable to regular, over-ground walking5 (when belt activation is linked to walker limb displacement); however, more research validating the comparability between treadmill walking and over-ground walking could be beneficial to the use of virtual reality for gait research, as well as worker training. For these reasons, virtual reality-based research may contribute to a decrease in the occurrence of slips, trips, and falls among workers and reduce financial burdens on employers and the health care system.

References

1. National Safety Council (2014). Injury Facts

2. http://www.bls.gov/news.release/pdf/cfoi.pdf

3. https://www.osha.gov/SLTC/etools/hospital/hazards/slips/slips.html

4. Yeo, Lockhart, and Wu (2013). Non-fatal occupational falls on the same level, Ergonomics, 56(2), 153-164. DOI: 10.1080/00140139.2012.746739

5. Sheik-Nainar and Kaber (2007). The Utility of A Virtual Reality Locomotion Interface for Studying Gait Behavior. Human Factors, 49, 696-709. DOI: 10.1518/001872007£215773.