First-Class Protection

Employers can ensure their sites comply with OSHA's 1910.133 eye and face protection standard by following the fundamental hierarchy of controls.

- By Fred Elliott

- Sep 01, 2015

An OSHA inspection earlier this year done as part of its National Emphasis Program for Hexavalent Chromium resulted in 12 serious violations issued against a Missouri company that makes food-grade stainless steel storage tanks for the biopharmaceutical industry. Violations of OSHA's respiratory protection standards and noise above the action level for an eight-hour shift were assessed along with $74,000 in proposed penalties. OSHA pointed out in its news release on the case that high levels of hexavalent chromium "can cause lung cancer and respiratory, eye and skin damage."

OSHA has an eye and face protection standard in its arsenal, 1910.133, which requires employers to "ensure that each affected employee uses appropriate eye or face protection when exposed to eye or face hazards from flying particles, molten metal, liquid chemicals, acids or caustic liquids, chemical gases or vapors, or potentially injurious light radiation." (1910.133(a)(1))

Also in the standard is the requirement that eye and face protection devices must comply with the ANSI/ISEA Z87.1-2003, American National Standard for Occupational and Educational Eye and Face Protection Devices. This consensus standard is now in its 2015 edition.

OSHA's regulations for head protection are 29 CFR 1910.135 for general industry and 1926.100 for construction. These are similar but not identical. The construction standard states that employees “working in areas where there is a possible danger of head injury from impact, or from falling or flying objects, or from electrical shock and burns, shall be protected by protective helmets.” The general industry standard says employers must ensure that "each affected employee wears a protective helmet when working in areas where there is a potential for injury to the head from falling objects." The head protection devices must comply with the ANSI/ISEA Z89.1-2009, American National Standard for Industrial Head Protection, now in its 2014 edition.

The Missouri case cited above showed the importance of basing protective measures on the well-known hierarchy of controls. OSHA said the employer allowed one employee to be exposed to hexavalent chromium at levels exceeding the PEL while welding and grinding steel that contained alloy steel, that the employer failed to implement engineering controls to reduce and monitor workers' exposure levels, and did not conduct additional monitoring after expanding its production process in 2006, 2008, and 2014.

Similar cases all too frequently occur in the U.S. private sector, according to OSHA. One such case was in Winter Haven, Fla., earlier this year. OSHA cited a refrigeration warehouse company for a total of 25 safety violations related to undone testing of its ammonia refrigeration system and training of its workers; OSHA proposed penalties of $116,100 after concluding the workers could have suffered eye, skin, and lung damage from exposure to high levels of ammonia.

It's safe to say that many head and facial injuries would not happen if more employers followed the hierarchy of controls and more workers refused to cut corners, reported near misses, and faithfully wore and maintained their PPE as recommended.

Following the Hierarchy of Controls

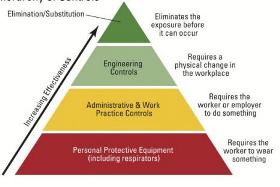

While graphics can render the hierarchy of controls in various ways, every U.S. safety professional should be familiar with the hierarchy's elements and their application. Safety hazards should be addressed with the most effective interventions, elimination or substitution (of a less-hazardous substance or operation) if possible, and the practitioner should move on to less-effective measures (engineering controls and administrative controls) only where elimination or substitution is insufficient or unavailable.

While graphics can render the hierarchy of controls in various ways, every U.S. safety professional should be familiar with the hierarchy's elements and their application. Safety hazards should be addressed with the most effective interventions, elimination or substitution (of a less-hazardous substance or operation) if possible, and the practitioner should move on to less-effective measures (engineering controls and administrative controls) only where elimination or substitution is insufficient or unavailable.

Using the hierarchy is a Prevention through Design (PtD) strategy, according to CDC. NIOSH offers information, publications, and additional materials about Prevention through Design at www.cdc.gov/niosh/topics.ptd/.

This article originally appeared in the September 2015 issue of Occupational Health & Safety.