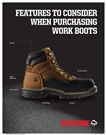

Proper Foot Protection Made Simple

Consider these important factors for safety and comfort.

- By Roger Huard

- Apr 01, 2013

Long hours on your feet without the appropriate footwear can equate to a miserable experience and, more importantly, a dangerous one. When you're selecting your next pair of footwear or building guidelines for your business, there are key components to consider that can make a significant difference in the safety and comfort of the footwear.

Established Guidelines and Standards

The Occupational Safety and Health Administration specifies that employers ensure each affected employee uses protective footwear when working in areas where there is a danger of foot injuries due to falling or rolling objects or objects piercing the sole, and also where an employee's feet may be exposed to electrical hazards. As an employer, clearly communicating guidelines about safety footwear will help ensure proper footwear is used. As an employee, making sure you fully understand the requirements is the first step.

Toe Protection and Metatarsal Guards

Toe protection is one of the key elements of foot protection. The American Society for Testing and Materials (ASTM) F2413-11 Standard Specification for Performance Requirements for Protective (Safety) Toe Cap Footwear is the standard safety-toe certification.

You will often see the standard listed as: ASTM F2413-11 M I/75 C/75

What does this mean? The letter "M" or "F" identifies the gender (male or female) for which the footwear is intended. The "I" stands for impact resistance (if something heavy were suddenly dropped on the foot), and the number signifies the impact resistance rating (75 foot-pounds). The "C" represents compression resistance (if something were to roll over or crush the foot) and the compression resistance rating (75, which represents 2,500 pounds of pressure).

Safety toe caps are commonly available in steel, aluminum alloy, and composite materials. Steel is the most common and time-tested material in toe protection. It is affordable and strong, and there are few materials that can meet or exceed the strength, resilience, and elasticity of steel. However, caps thermo-formed from resins and fiberglass composites are becoming more and more popular. They meet the same safety standards and provide the same level of protection as steel with some notable benefits: They are lighter in weight, they do not conduct heat or cold in extreme temperatures, and they are non-metallic (allowing for easier passage through metal detectors, etc.) However, composite toe caps do need to be slightly bigger and thicker than steel toe caps in order to offer the same protection, so they can make boots look bigger and fit differently to some users.

Metatarsal guards take the protection the next level. They cover the front of the foot and helping to prevent or reduce the severity of an injury to the metatarsal and toes. You will see metatarsal guards identified as Mt/75, where the metatarsal guard and the rating (75 foot-pounds) are identified.

Other Rated Components

Other common ratings include electrical hazard (EH), conductive (CD) properties, puncture resistance (PR) properties, and electric static dissipative (ESD) properties.

EH stands for electrical hazard. Electrical hazard footwear is made with insulative electrical shock-resistant outsoles and materials. It's designed to provide secondary protection against contact with live electrical circuits and electrical conductors, parts, or machinery. Footwear with an electrical hazard designation must be able to withstand 18,000 volts at 60 hertz for one minute with no current flow in excess of 1.0 mill amperes, in dry conditions.

Conductive footwear helps to protect the wearer in environments where static electricity accumulation is a potential hazard. Footwear with a CD rating is designed to dissipate static electricity from the body to the ground. The electrical resistance should range from zero to 500,000 ohms.

Closely related is static dissipative footwear, which helps reduce an accumulation of static electricity by conducting body charge to the ground.

Puncture-resistant footwear helps protect against injury that could be caused by sharp objects that could penetrate the outsole. The puncture resistance must be built into the shoe during the manufacturing process. This is often executed with a puncture-resistant plate that is built into the midsole of the shoe. Puncture-resistant footwear must be able to endure at least a 270-pound force and also show no sign of cracking after 1.5 million flexes, to ensure long-lasting protection. If the puncture-resistant midsole or insole is metal, it also must pass a corrosion resistance test.

Comfort and Performance Features

In addition to safety standards, there are numerous components of work boots that impact their comfort and functionality, including outsole materials, upper materials, waterproof features, insulation value, and construction type.

Outsole Material

Genuine rubber is the most commonly used material, and the reason is simple enough: Rubber offers excellent performance in terms of abrasion and oil- and slip-resistant qualities that are needed in a work boot where durability and performance are critical.

The main advantage of newer materials such as TPU (thermoplastic polyurethane), PU (polyurethane), and EVA (Ethylene-Vinyl-Acetate) is that they are lighter in weight, more flexible, and, in the case of PU and EVA, provide greater cushioning. Many modern work boots offer combinations of these synthetic materials and rubber. Advances in chemistry and chemical engineering also have allowed boot developers to fine-tune the performance characteristics of outsoles so that there is a more focused match between outsole performance and function.

Upper Material

Synthetic materials were rarely found in work boots as recently as 20 years ago. However, as people move toward work boots that look and feel more like athletic footwear, the performance and value of synthetics has begun to challenge the dominance of leather in work boots. Made from a constantly increasing variety of man-made fibers and resins, most synthetic materials (including synthetically enhanced leather) are lightweight, durable, and can be formulated to be waterproof.

Although synthetics are gaining popularity, leather is still the tried and true upper material found in many work boots. Leather is breathable and a good choice for people who are on their feet for hours at a time. Leather provides a customized fit for each individual because leather molds to the foot with wear, and leather is by nature quite durable and can be treated with a waterproof compound for additional performance.

Waterproof Components

In addition to waterproof uppers -- whether it’s leather, synthetic, or a combination of the two -- there are components that can supplement the waterproof nature of a work boot. A waterproof membrane guarantees that feet stay dry in wet environments while maintaining breathability.

Insulation

Insulation is an important consideration for many people around the country who work outside, especially in wet and cold environments. Insulation typically ranges from 200 grams for light warmth up to 1200 grams intended for the coldest, harshest conditions.

Construction

There are many different construction methods used in boot-making, and the manner in which boots are constructed makes a difference in the weight, flexibility, and longevity of a boot. Goodyear Welt is time-tested and durable construction that has been used for many years. It provides durability for footwear because the upper and inner sole are stitched together with a strip or “welt.” In the next step, a firm midsole is stitched to the welt. Finally, the sole is cemented (and sometimes also stitched for extra security) to the midsole. This process allows boots to be re-soled or repaired, thus extending the longevity of the footwear.

A modern and popular type of construction is cement, where the boot's outsole and midsole are cemented permanently to the upper. This construction is lightweight and flexible. Direct-Attach (or Injection) is a boot construction where the sole material is permanently and chemically fused or attached to the upper. This construction is very lightweight and is generally the most durable and flexible type construction. It also has the added benefit of being watertight. Finally, there is opanka construction (or side stitch), where an upper is directly sewn to the sole. This unique construction is achieved by hand-sewing the upper, sock lining and outsole in a single process, delivering comfort and flexibility.

This article originally appeared in the April 2013 issue of Occupational Health & Safety.