Comprehensive NFPA 70E Training for Qualified Workers

Proper training can enable employees to approach situations with safety in mind.

- By Bill Belongea

- Dec 01, 2022

If there was one positive takeaway from the COVID-19 pandemic, some would say it was businesses’ renewed commitment to safety and implementation of additional protocols that protect their employees. As facilities continue returning to normal operations, it’s imperative that organizations keep the momentum going and consider other areas in which they can strengthen their employee safety programs.

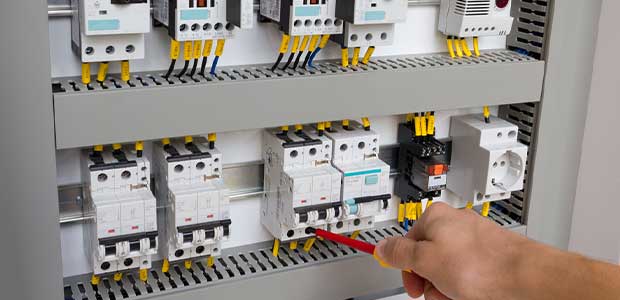

Electrical workers in particular face many hazards on the job, such as damaged tools and equipment, inadequate wiring and overloaded circuits, exposed electrical parts, damaged insulation and wet conditions and the most common OSHA electrical violation, improper grounding. However, few are more devastating than an arc flash, which is an electrical release of energy that can be hotter than the surface of the sun.

Though the nature of commercial industries and the type of equipment used can present dangerous situations, the reality is that many electrical injuries can be prevented if companies are committed to developing a strong electrical safety policy and training programs. To navigate today’s electrical safety requirements and build a proper electrical safety program, an organization must first ensure it has qualified workers that have received the proper in-depth training to complete electrical tasks safely, using the latest NFPA 70E standard as their guide.

Who is Considered a “Qualified Worker?”

The NFPA 70E standard defines who is considered a qualified worker so that there is no mistaking if an employee is equipped to perform specific electrical activities—and for good reason, considering the dangerous hazards that electrical tasks often entail. According to NFPA 70E 110.2(A)(1), “a qualified person shall be trained and knowledgeable in the construction and operation of equipment or a specific work method and be trained to identify and avoid the electrical hazards that might be present with respect to the equipment and work method.”

It’s important to note that with this definition, being deemed a qualified worker does not necessarily mean that a specific employee will be allowed to perform all the electrical tasks within the facility. NFPA 70E requires a risk assessment of all the electrical tasks that need to be completed. This assessment will determine which tasks qualified workers are able to perform and which must be outsourced to third parties.

Developing Comprehensive Training Programs for Qualified Workers

Once an organization has identified all the tasks its qualified workers will be performing, the next step is to evaluate who will be selected as a qualified worker and the type of training they will need.

As the organization is determining its electrical risks, it is also important to understand that all qualified workers are not alike. There are differences in knowledge, skill and experience, which determine the level, content and nature of the training required for each individual. The electrical safety training course instructor doesn’t designate a qualified worker—the employer does—making it important for employees to clarify which scenarios are safe given their training and to identify where further instruction is needed for the installation and operation of a given electrical system.

To perform any electrical tasks, qualified workers must be trained based on the NFPA 70E Standard. This course should be taken once upon completion of initial training and then an NFPA 70E refresher every three years unless inspections, behaviors, changes in equipment and technology or changes in job duties require it to be retaken more frequently. Per NFPA 70E 110.2(4), training “…shall be classroom, on-the-job, or a combination of the two. The type and extent of the training provided shall be determined by the risk to the employee.” In addition to the NFPA 70E standard, OSHA CFR 1910.332 outlines training requirements for electrical work activities, including skills and techniques to “distinguish exposed live parts from other parts of electric equipment,” and the ability to “determine the nominal voltage of the exposed live parts.”

This hands-on requirement is one of the biggest differences between the typical OSHA compliance training that many businesses are used to and the NFPA 70E standard, which mandates technical, hands-on training for employees beyond simply training with supervisory oversight. This is because NFPA 70E training must also often be customized to an organization’s assets—such as panels, equipment, PPE—procedures and practices are best learned by doing the work.

For the most effective training, businesses should consider implementing an internal program for qualified workers that includes both classroom and hands-on training of the qualified workers' specific tasks. That way, the training program can be tailored to individuals based on their ability and the risks associated with their specific electrical tasks.

Part of a qualified worker’s training should also include an understanding of the required PPE based on the incident energy of the electrical device they are working on. Proper HRC/CAT rated clothing is the required form of protection when performing live electrical work, so qualified workers should ensure their clothing rating reflects the hazard category associated with the equipment they will be working on or in the vicinity of. Without proper PPE, the risk for serious injury can increase substantially.

Leveraging Third-Party Support

When it comes to electrical safety, there are often varying interpretations on what is required versus what is best practice, as businesses must keep up with multiple governing entities that determine industry standards and guidelines. Organizations may find NFPA 70E compliance to be confusing, as it requires training to be completed every three years, when the standard itself is updated.

To ensure companies are receiving the most objective and up-to-date training for their qualified workers, businesses should engage a trusted third party to complete an arc flash risk assessment and offer guidance on qualified worker training. Companies offer specialized services in electrical safety and can help businesses implement a training program based on the latest industry standards and regulations, as well as the organizations’ own written electrical safety policy. The 2021 edition of NFPA 70E is now in effect, so third-party providers have also refreshed their training and best practices based on the 2021 edition requirements.

Conclusion

All job sites come with inherent safety risks, but at the end of the day, electrical safety standards like NFPA 70E are designed to keep people safe and out of harm’s way. It is crucial that an organization’s qualified workers be trained to have not only the skills but also the safety practices and PPE to protect themselves on the job. By understanding how to define and train a qualified worker, organizations can empower their employees to approach each situation with the right training, tools and gear that will keep them safe and keep all facility operations running smoothly.

NOTE: This information is intended to help guide facilities and its personnel. However, proper implementation, training and compliance is the responsibility of the facility and its operators.

This article originally appeared in the December 1, 2022 issue of Occupational Health & Safety.