Workers Exposed to Amputation Hazard at Wood Crate and Pallet Facility, Officials Say

The company was cited for serious and repeat violations.

- By Alex Saurman

- Aug 05, 2022

Workers at a Texas facility were exposed to amputation hazards, OSHA says.

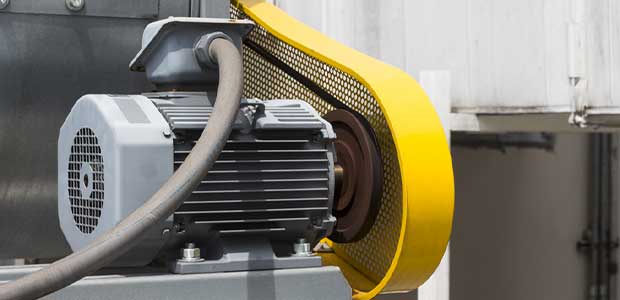

According to a press release, M&H Crates Inc. “failed to ensure machine guarding,” leaving workers exposed to this hazard and others. OSHA also found the company did not have procedures for lockout/tagout.

Following the February 2022 inspection, initiated after a complaint was filed, the wood crate and pallet manufacturer was cited for serious and repeat violations. OSHA proposed penalties of $248,866.

In the past, M&H Crates Inc. was cited after other inspections. In 2020, OSHA inspected the company after a worker had a finger amputated. OSHA found the saw the worker was using did not have guarding.

“M&H Crates Inc. continues to expose its employees to dangerous workplace hazards by ignoring required federal safety standards,” explained OSHA Area Director Basil Singh in Dallas in the press release. “These safeguards can be the difference between ending a shift safely and suffering a serious and life-altering injury. M&H Crates must develop and implement a company culture where worker safety and health is a priority.”

Lockout/tagout and machine guarding are some of the most frequent OSHA citations.

About the Author

Alex Saurman is a former Content Editor for Occupational Health & Safety,who has since joined OH&S’s client services team. She continues to work closely with OH&S’s editorial team and contributes to the magazine.