How Much Awareness is Too Much Awareness?

We are already struggling to tread water in a sea of devices vying for our attention. When connected safety programs are properly implemented, these can be a life raft, and with some work, a speed boat to navigate these waters.

- By Kyle Krueger

- Mar 01, 2019

Our personal and work lives are now inundated with notifications and alerts. We convince ourselves that our increased awareness will have significant benefits. Bing! You have a new e-mail. Ding! Your weekly status report is due. Dong! You have a new friend request. Beep! Beep! Beep! You are currently in a hazardous atmosphere. These are all vying for our attention in an attempt in improve our awareness. However, to even the most seasoned awareness warrior, these become a flurry of buzzes, rings, dings, and beeps that can become a mundane hum, an ordinary part of our day.

We are so accustomed to being "aware" that awareness has lost its meaning. We now judge many of our buying decisions based on the capacity of devices and systems to make us more aware. Anything that can’t deliver an alert 24/7 is seen as inferior. While we have seen significant improvements because of technology, we are now at an interesting tipping point. How much awareness is too much awareness? Are we just dumping these alerts into a vast hole? Why did we want the awareness in the first place? What is the point?

Although this is not intended to be a "those darn kids and their technology" piece, it is intended to challenge and put these alerts and awareness into perspective. While our consumer lives have adapted (or attempted to adapt) to a fast-moving wave of innovation, the safety industry is just now getting readily available "connected devices." My concern is that unlike other "awareness" about news events, restaurant reviews, or cute kid photos, a level of safety awareness can drive significant change in the workforce. However, if the industry gets too wrapped up in the material aspect of alerts and the devices that create them, we can quickly shut the door on an even brighter future.

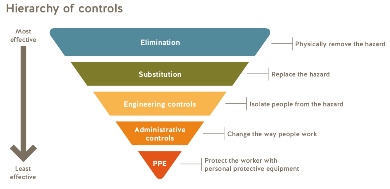

If any of you have read my prior articles, you will understand how I loathe that gas detectors are viewed as PPE. Gas detectors don't protect you from anything; rather, they make you aware of the atmosphere. The protection comes from acting properly with the information. And from someone who has made a career "geeking" out on gas detectors, I say that from a place of love, not hate.

Accordingly, an alert from an awareness device is just one more person being aware that a hazardous condition currently exists. If this is indicative of an acute life-threatening incident, I am not downplaying the importance. It is significant. However, I do think we need to question whether knowing when everything has fallen apart quicker is truly a marketable improvement in safety.

What I believe would be a truly marketable improvement in safety is to view these alerts and awareness through the lens of the hierarchy of controls. An alert from a "PPE" device is still at the bottom of the pyramid. However, it has the potential for upward momentum. If we can aggregate this data to change how people work, isolate them from hazards, and eventually eliminate hazards. If we do that, we can tap into the full potential of connected safety. These insights can change the way thousands of people work and hopefully save hundreds of lives. Maybe then we can work to make sure people aren't placed in "alert worthy" situations.

However, when these alerts are broadcast into bottomless pits, so is our ability to eliminate death on the job. Just because we can place more sensors on more people that generate more alerts doesn't mean the problem is being solved. Putting more sensors that prompt more alerts to people who are continually put in the same situation with no feedback is the equivalent of walking through a busy intersection while texting.

What Can We Do Better?

When we are having our collective "connected" conversations in the workplace, we would be wise to have a strategy to take advantage of the truly valuable long-term aggregate data and insights that are currently a "nice to have" byproduct of a connected awareness device.

Before you invest, make sure you have clearly defined goals and expectations for the program. Let's be clear, your organization isn't buying security—they will be buying awareness, a lot of it. Conversely, your risk profile hasn't increased, it will be the same as before (i.e., your alarms won't go away). However, your ability to manage and understand risk will improve greatly. Initially it will have a "turning on the blacklight" effect on your organization if not managed properly. Be prepared and have a rollout plan.

By investing time and brain power in data, we can shed light on the daily normalization of deviation. Actions such as turning off monitors in alarm, not bump testing, or continuing to work in the area that "has always been gassy" can now become behavior of the past. Aggregate data can clearly illustrate problem areas of the facility that can drive engineering controls. Combined, we can take a giant leap to eliminate the most dangerous activities altogether.

We are already struggling to tread water in a sea of devices vying for our attention. When connected safety programs are properly implemented, these can be a life raft, and with some work, a speed boat to navigate these waters. Otherwise, you may end up drowning your organization and people in noise.

This article originally appeared in the March 2019 issue of Occupational Health & Safety.