Safety Professionals, 'We've Got a Problem'

Choose hand protection solutions via form, function, and fit.

- By Mary Padron

- Jun 01, 2018

Astronauts wouldn't dare go into their work "space" without wearing protective gear, especially hand protection, which is a critical component of a space suit. Even though space gloves are incredibly bulky and non-dexterous–a common work glove complaint of workers–astronauts always wear them because they understand the danger and life-threatening consequences of not wearing safety gear. For astronauts, it's simply not an option to forego wearing space PPE because it literally saves their lives.

How can we channel the astronaut's "must wear PPE" attitude toward safety among our global workforce? How can we motivate workers to willingly wear their hand protection like astronauts do? We motivate them by providing them with the appropriate glove for the task. That glove should be comfortable and fit properly.

We encourage them to wear it through proper training and the constant reminder that hand protection is a crucial part of the worker's well-being. After all, if someone suffers a serious hand injury, such as losing a finger or the functional use of a hand, the quality of his or her life declines immensely. Hand protection protects a person’s well-being, not just the hands, fingers, and wrists.

Safety Professionals, 'We've Got a Problem'

In the movie Apollo 13, directed by Ron Howard and starring Tom Hanks, the phrase "Houston, we've got a problem," entered the mainstream culture. Although hand protection is evolving quickly like spacesuits due to technological and scientific breakthroughs that improve protection, comfort, and dexterity, the statistics for hand injuries still remain problematic.

According to the Bureau of Labor Statistics (BLS) and other sources, here are some of the numbers that reveal the severity of hand injuries:

- Seventy percent of workers who experience hand injuries are not wearing gloves when the injury occurs.

- Thirty percent of workers are wearing inadequate or inappropriate hand protection.

- One million workers are sent to emergency rooms annually because of hand injuries.

- There are 250,000 serious injuries to fingers, hands, and wrists each year, propelling hand injuries to the second-leading cause of work-related injury (back and neck injuries take first place).

- The average hand injury claim exceeds $13,000 when medical claim and workers’ compensation claims are coupled together.

- The National Safety Council (NSC) reports that a severed tendon typically costs $70,000, a laceration $10,000, and stitches $2,000.

Hand Protection Solutions Via Form, Function, and Fit

Spacesuits have evolved into machines of impressive complexity, even becoming miniature spacecraft that fly independently. Hand protection has grown increasingly complex, too, with all of the choices offered in the marketplace. From super yarns for high levels of cut protection to advanced palm coatings and thermal plastic overlays, choices for hand protection are immense and varied.

Astronauts know that NASA has chosen their spacesuit and gloves with methodical and scientific reasoning. After all, the astronaut's life depends upon it. Safety professionals should specify hand protection with methodical and scientific care in order to choose the perfect glove for the worker in his or her job environment.

Providing workers with the right gloves for the application will motivate them to willingly wear their gloves. The safety professional's understanding of the importance of glove form, function, and fit leads to accurate glove selection and increased worker compliance.

Form: What is Your Glove Made of? Materials, Fibers, and Coatings

Materials

When selecting hand protection, safety professionals must consider the material of the glove. Ideally, the material should provide comfort, the appropriate protection for the task, and dexterity. Common glove materials include natural leather, synthetic leather, and fabric gloves that are machine stitched.

Natural leather comes from cow, goat, or pig. It is soft to the touch, tear resistant, durable, and has high tensile strength; however, like human skin, it doesn't provide high levels of cut resistance. Synthetic leather has similar properties to natural leather but is man-made.

There are many synthetic and natural fibers that are used to make fabric glove shells. Glove shells are knitted on a flat head knitting machine and are measured by the gauge (ga) of the shell: The smaller the gauge, the thicker the shell. Seven gauge is the thickest shell and 18 gauge is the thinnest, lightest-weight shell. If dexterity is of paramount importance, then you will need to select a glove with a high gauge.

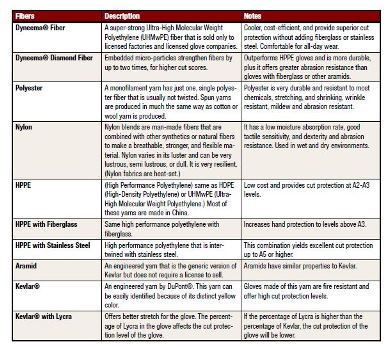

Fibers

Just as our hands are made of tendons, ligaments, bones, and nerves, glove shells are composed of fibers. Not all fibers are created equal, and picking the wrong fiber for your glove is a common error in fabric glove selection. Two primary types of fibers are filament fibers and staple fibers.

Filament fibers are longer, lined up, and bundled. They produce products with higher tensile strength that resist breakage under tension. Staple fibers are shorter in length and are mechanically twisted to form a variety of sizes.

Machine knit glove shells can be made from many different types of materials, including natural fibers, synthetic fibers, and fiber blends. Natural fibers are plant based and include cotton, bamboo, wool, silk, and hemp fibers. Man-made synthetic fibers, such as polyester and nylon, are frequently used in glove shells.

Typical fibers for blended yarns include cotton, acrylic, nylon, and polyester. The blend of polyester, nylon, and cotton fibers offers extra durability and strength while maintaining the comfort benefits of cotton. Blends help manufacturers develop a variety of gloves to satisfy a wide range of applications.

Common glove materials are listed in this chart.

Coatings

Coated gloves are ideal for jobs that require a high degree of touch sensitivity, dexterity, and a superior grip. Industrial applications include general assembly, painting, the handling of small oily parts and components, horticulture, machining, and maintenance.

Glove coatings:

- improve the gripping power of a glove

- increase the glove’s resistance to puncture and abrasions

- offer protection from liquids and chemicals

Common glove coatings include nitrile, latex, and polyurethane (PU).

Nitrile gloves, an industry staple, hold up well to gasoline, turpentine, acids, bases, oils, and diesel fuel. They are generally stronger and more puncture resistant than latex gloves. They are available in different finishes, such as smooth nitrile, foam nitrile, and sandy foam nitrile.

Latex gloves, which are one of the most recognized glove materials in the world, resist acetone, thinners, and ketones but often cause allergic reactions if the wearer is over-exposed to the product. Semi-smooth texture is extremely flexible and provides superior dexterity and sensitivity. Latex gloves are also available in different finishes, including foam, sandy foam, and crinkle latex. Rough finishes on gloves improve the worker’s grip.

A PU coating can be silicone free and has a low-particulate shed, which reduces risk of contamination from the dip itself. The coating "strikes through" onto the inside of the glove, which can lead to heat retention and sweating. Not as durable as nitrile or latex, PU gloves can be used for inside light duty, detailed assembly, inspection, light fabrication, and box/small parts handling.

Function: 'Danger, Will Robinson'—Matching the Glove to the Risk

Since we don't have a robot (yet) that informs us of impending danger as Will Robinson does in the Netflix adaption of Lost in Space, choosing the right glove for your safety program requires safety professionals to conduct a proper PPE hazard and risk analysis, also known as a "risk assessment."

Put on your detective hat and ask these questions to discover the dangers lurking in your workspace.

- What specific risks are present in your facility that could put your employees' hands, fingers, thumbs, and wrists in danger?

- Can these risks be eradicated via engineering or administrative controls, such as putting up guardrails on machinery (engineering) or regular inspections of work spaces by safety officers to ensure employees are wearing their gloves (administrative)?

- What glove features are required to safely protect against the risk, especially if engineering or administrative controls aren't feasible or possible?

- Do you need a Cut Level A3 or does the task require A7 cut protection? Do you need a coated glove with a crinkle latex finish or will a typical coated glove work? Does the glove need a thermal layer? Does it need thermal plastic overlays for enhanced impact resistance?

The questions are many and the answers can be complicated but you need to know: You are not alone. Most leading glove manufacturers and suppliers have product managers, product champions, and trained safety specialists who can help with risk assessments and specify the perfect glove for your safety program. Don't hesitate to call and get the support you need to help protect your workforce.

For more information about engineering, administrative, and PPE controls, visit OSHAcademy at https://www.oshatrain.org/courses/pages/700engineer.html.

Fit: If the Glove Fits, Comfort and Compliance Skyrocket

Just as people don't like to wear shoes that are too small or too large, they don't like to wear gloves that don't fit. However, far too many workers are thrown into situations where they are wearing work gloves that don't fit.

Proper sizing of work gloves will manifest itself into improved compliance statistics. Gloves that are too small or too large can interfere with productivity and lead to hand injuries. Improperly sized gloves are uncomfortable so workers will frequently remove them. Gloves that are too large can often get caught in machinery, which can cause serious hand injuries. Gloves that are too small can cause hand fatigue. It seems like common sense but far too many workers wear gloves that don't fit them. Gloves that are too tight may lead to increased sweating, which nobody likes.

Determining proper glove size

Encourage employees to measure their hands using a sizing chart. To determine the proper glove size, use a soft cloth tape measure to measure your dominant hand as in the image below.

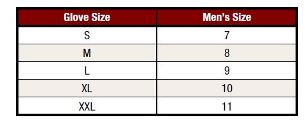

For gloves that come in numbered sizes, match your measurement to the size listed. For example, if the measurement is seven inches, then select a size seven glove. If the measurement is over seven inches, then choose the next size larger to avoid hand fatigue, in this case a size eight.

If the gloves are offered in lettered sizes, such as S, M, L, XL or XXL, convert to a numerical size using a size chart. Sizes can be different among manufacturers, so you will want to confirm the sizing chart that your supplier uses. Some charts include half sizes and some do not. Here is an example of a size chart in whole sizes:

The Goldilocks Zone and Gloves

NASA often refers to the Goldilocks Zone in space when trying to find new planets that are "just right" for human habitation. Gloves have a Goldilocks Zone, too. Selecting the glove with the specific features that are "just right" for the task and selecting the glove that fits the worker's hand "just right" will do wonders for your safety program.

Couple this with motivational training that reminds workers that safety is more than just following OSHA rules and avoiding citations or HR reprimands. Wearing PPE at work is often life-saving, like spacesuits, especially when the PPE protects against struck-by accidents, slips and falls, and head injuries.

Remind your workers on a regular basis that safety is also about maintaining the worker's well-being and quality of life, especially when it pertains to vision, hearing, and hand injuries, which often aren't life threatening. But these types of injuries negatively compromise your lifestyle and your relationships at home and at work.

Finding new, perfect planets is not an easy task. But finding the perfect glove can be, especially when you reach out to PPE manufacturers, suppliers, and distributors who are knowledgeable and passionate about hand protection. You are not alone!

This article originally appeared in the June 2018 issue of Occupational Health & Safety.