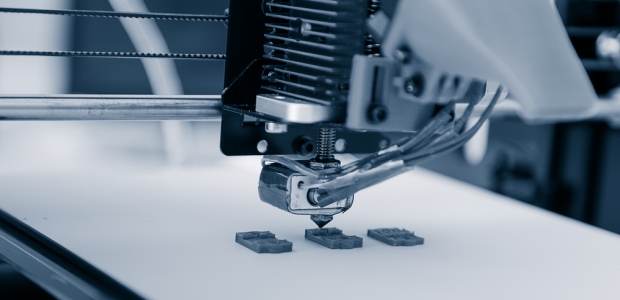

FDA Offers 3D Printing Guidance to Medical Device Makers

The agency claimed Dec. 4 to be the world's first to provide a comprehensive technical framework to advise manufacturers creating medical products on 3D printers.

FDA published "Technical Considerations for Additive Manufactured Medical Devices," a guidance document for industry and the FDA staff, on Dec.5 and said

it is the world's first agency to provide a comprehensive technical framework to advise manufacturers creating medical products on 3D printers.

A draft of the document was issued on May 10, 2016, according to FDA.

The guidance addresses a variety of issues, from design, software, and materials (both starting materials and reuse of materials) to post-processing, device testing, biocompatibility, and labeling.

A Dec. 4 statement from FDA Commissioner Dr. Scott Gottlieb said that "3D printing of medical devices, medications, and human tissue is quickly becoming a promising reality. Patients have already benefitted from 3D printed medical products through access to personalized devices and innovative drugs that have led to significant health improvements. But the FDA is now preparing for a significant wave of new technologies that are nearly certain to transform medical practice. We're working to provide a more comprehensive regulatory pathway that keeps pace with those advances, and helps facilitate efficient access to safe and effective innovations that are based on these technologies."

He said the agency has reviewed more than 100 devices currently on the market that were manufactured on 3D printers, such as knee replacements and implants designed to fit into a patient's skull for facial reconstruction. FDA also has approved the first drug produced on a 3D printer. "This is likely just the tip of the iceberg given the exponential growth of innovative research in this field. We envision that burn patients in the near future will be treated with their own new skin cells that are 3D printed directly onto their burn wounds. Further down the road, there is the potential for this same technology to eventually be used to develop replacement organs," he added. "We're also helping to advance the field of regulatory science with state-of-the-art 3D printing facilities located on the FDA's campus. The Center for Drug Evaluation and Research's (CDER) facility enables FDA scientists to conduct research to determine how the 3D printing of drugs impacts inactive ingredients and other drug components as well as the quality control process of manufacturing. FDA engineers in the Center for Devices and Radiological Health (CDRH) have been conducting research using their own 3D printing facility to investigate the effect of design changes on the safety and performance of devices, and to determine how iterative changes alter the device’s fit and functionality. Such answers could, for example, help improve the effectiveness and comfort of prosthetic devices. This research also helps inform us as regulators to help us understand the policy framework needed to ensure the quality and safety of 3D printed products."

He explained that the technical guidance "is only intended to provide the FDA's initial thoughts on an emerging technology with the understanding that our recommendations are likely to evolve as the technology develops in unexpected ways. We are already seeing the beginning of this evolution as hospitals and academic centers use their own 3D printers to create innovative dental implants, replacement knee joints, and experimental heart valves and bone implants for use in clinical studies. An increasing number of surgeons across the country have been saving infants born with a life-threatening breathing condition by creating patient-matched 3D-printed splints to install in their patients’ tiny airways, which expand and degrade as the babies grow.

"In order to help ensure the safety and effectiveness of these products, we're working to establish a regulatory framework for how we plan to apply existing laws and regulations that govern device manufacturing to non-traditional manufacturers like medical facilities and academic institutions that create 3D-printed personalized devices for specific patients they are treating. Developing a transparent policy on 3D printing remains an important next step for us, and we plan to explore the role of nontraditional manufacturing facilities like a hospital operating room or university laboratory," he said.

The commissioner also said FDA plans to review the regulatory issues related to the bioprinting of biological, cellular, and tissue-based products in order to determine whether additional guidance is needed beyond the recently released regulatory framework on regenerative medicine medical products.