Proven Methods for Reducing Noise Exposures

Noise dosimetry may be necessary if the workplace noise levels vary throughout the day or if the workers are mobile, driving vehicles, or working in areas where it is either unsafe or impractical for a sound level meter to be used.

- By James Tingay

- Oct 01, 2016

Many of us work in environments where noise is a hazard that we encounter daily. Although changes in work patterns and the use of quieter and more efficient machinery have reduced noise levels in recent decades, it is still a major occupational hazard.

It is estimated that 22 million workers in the United States alone are exposed to hazardous noise levels in the workplace each year1 and an estimated $242 million is spent annually on workers’ compensation for hearing loss disability.

Wherever there is noise in the workplace, you should be looking for alternative processes, equipment, and/or working methods that would make the work quieter or would ensure that people are exposed for shorter durations, reducing the risk of workers suffering damage to their hearing.

Controlling noise risks and noise exposures should be where you concentrate your efforts. By carrying out a noise assessment, you can identify the risks that your workers are being exposed to and, from that, create an action plan for controlling these exposures.

Understanding What You Need to Measure

Before starting on implementing a noise control program or even before starting out measuring and assessing noise levels, take a moment to consider what you are trying to achieve.

Typically, you will be making noise measurements for compliance with noise regulations, so you should consider any requirements that those regulations put in place and how these may affect the way that you carry out your noise measurements.

First, consider how the standards require that noise exposure is measured and reported. Almost every occupational noise regulation requires that exposures are measured in terms of a time weighted average (TWA) over a standard working day. However, there can be subtle variations between standards, which can result in dramatic differences in the reported results1.

OSHA's permissible exposure limit is 90 dB(A) for an 8-hour day, and this standard uses a 5dB exchange rate. NIOSH has recommended that all worker exposures to noise should be controlled below a level equivalent to 85 dBA for eight hours. NIOSH also recommends a 3 dB exchange rate as opposed to the 5dB required under the OSHA standard.

What this means is that a constant level of 100 dB(A) for 8 hours would be reported at 200 percent against the OSHA PEL and 3,200 percent against the NIOSH recommendations.

Understanding what the regulations require and how your measurement equipment works is essential to ensure that the information you gather is both correct and robust, otherwise there is a risk of reporting the wrong information.

What Are You Measuring?

Before you start on the noise measurements themselves, you should be clear about whether the noise levels that you are about to record will be a true record of the worker’s exposure.

In the ideal world, you would be continuously measuring and assessing noise exposures because this would allow the variability of work patterns to be assessed over a long period. However, for most people this is not practical, and so it is essential that any measurement made is representative of the long-term exposure and can be used as an effective assessment of risk.

Consider these points:

- Are the workers who are to be measured carrying out typical activities?

- Are the workers being measured in what would be their normal work environment?

- Is the noise being measured typical of that in a normal working day?

- Has any new equipment been installed recently or is any old equipment due to be removed?

- Are there any environmental aspects to consider, such as the weather?

- Are there any other factors that could influence or affect the measurements that could be considered to be out of the ordinary?

You should also consider where you will make the measurements. Noise dosimetry may be necessary if the workplace noise levels vary throughout the day or if the workers are mobile, driving vehicles, or working in areas where it is either unsafe or impractical for a sound level meter to be used.

If you are using a noise dosimeter, the microphone will typically be within 4-6 inches of the ear, but you should also consider making measurements on both sides of the head if the noise source is coming predominately from one direction.

If you are using a sound level meter, think carefully about where the microphone is positioned.

It’s not uncommon to see measurements being made with a sound level meter where the microphone is several feet away from the ear of the worker. Is this representative of the noise levels being received into the ear? If not, think about how this can be improved and try to get closer to the worker. Safety aspects may prevent this (for example if you are measuring welders, it may not be safe to get close), so if this is the case, ensure that you document this with your measurement results.

By recording information about the position where they were made, you will be able to ensure that any follow-up measurements can be made in the same place.

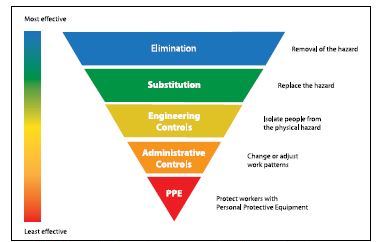

Implementing a Hierarchy of Controls

Once you have carried out any noise measurements and have identified any employees who are exposed to noise levels at or above the legal limits, you should look at what are the most effective ways to protect them.

By considering the hierarchy of controls, we can look at each stage and determine how these can be used.

Elimination of the Noise Source

Protection is best achieved by controlling the noise at source, and so the most effective way to manage noise exposures in the workplace is always by the elimination or removal of the sources that contribute the most to the overall noise exposures.

Noise is a common aspect of our working lives and although significant advances have been made that have allowed equipment to be designed that produces lower noise levels, there are still many activities where noise is an inherent part of the job and where is it not possible to completely remove it. For example, material recycling facilities often have processes which emit very high noise levels that can frequently exceed 85dB(A). These processes are inherently noisy, so it’s usually not possible to eliminate the noise sources without significant impact upon the operation.

However, elimination of the noise source should always be the first action to be considered.

Substituting the Noise Source

Replacing the noise hazard is the next step in our hierarchy of control. Consider whether it is possible to do the work in some other quieter way. Look at whether changes to consumable parts (such as saw blades, exhaust valves for compressed air, etc.) are possible and whether newer technology allows for lower noise levels.

The introduction of a low-noise, or Buy Quiet, purchasing policy can help to maintain the aim of a long-term reduction in noise levels.

Many equipment manufacturers are now considering low noise levels as a significant selling point and will be able to provide information about typical noise levels from their products. As long as the test methods used are comparable, equipment with lower noise levels would be preferable.

Engineering Controls

Using engineering controls to reduce noise levels often can provide the widest range of solutions, many of which can provide small reductions but can contribute to significant change when added together.

Engineering controls usually involve modifying, repairing, or replacing equipment or making changes at the noise source or along the transmission path to reduce the noise level at the worker’s ear. Some of these can be small, simple things such as ensuring that machinery is lubricated and maintained regularly. Repairing loose machinery guards can often be a simple task but one that can yield significant results.

Some other examples of engineering controls include:

- Avoiding metal-on-metal impacts (e.g., line chutes with abrasion-resistant rubber) and reducing drop heights

- Damping vibrating machine parts—anything that is vibrating will be transferring vibrations into the air, which we hear as noise

- Isolating vibrating machinery or components from their surroundings with anti-vibration mounts or flexible couplings

- Fitting or replacing silencers to air exhausts and blowing nozzles

It may also be possible to modify the paths by which the noise travels through the air to the people exposed by:

- Installing enclosures around machines to reduce the amount of noise emitted

- Using barriers and screens to block the direct path of sound

- Positioning noise sources farther away from workers

- Using absorptive materials within the building to reduce reflected sound

Administrative Controls

Where it is not possible to eliminate the noise source, replace it with a lower-noise version, or use engineering methods to reduce the noise levels, changes to working patterns may be required to reduce exposures. For example, handheld concrete breakers can produce noise levels in excess of 95 dB(A) at the ear,2 and it may not be possible to reduce the noise levels when this equipment is operating.

By using administrative controls, the exposure of both the worker using the equipment and others in close proximity can be reduced.

Examples of administrative controls include:

- Limiting the amount of time that a worker can use noisy equipment

- Using noise equipment at times when fewer people will be exposed

- Providing quiet zones or noise refuges where workers can spend breaks or take time away from high noise levels

- Using high-visibility warnings when noise equipment is being used to increase awareness of the potential risk

- Ensuring workers who are not using the equipment are kept at a suitable distance from the noise source

Keeping people away from noise sources when they are not working or not using the equipment can be an effective way to manage noise exposures, but it often requires training to be done to ensure that workers understand the need to keep their distance.

Don't forget that in open space, every time the distance between the noise source and the worker doubles, the noise level is reduced by 6dB!

Hearing Protection (PPE)

Most, if not all, occupational noise standards and regulations consider the use of PPE (Personal Protective Equipment) is to be the last resort that should be used only where none of the other control measures can reduce the noise exposure to acceptable levels.

It may be appropriate to use PPE to manage noise exposures while other control measures are being implemented and where additional protection is required for workers whose hearing tests show significant hearing loss or damage.

By following the hierarchy of controls, we can work through the possible solutions to eliminate, remove, or reduce noise exposures and ultimately protect our employees from the risk of hearing damage.

References

1. https://www.acoustics.asn.au/conference_proceedings/INTERNOISE2014/papers/p366.pdf

2. https://www.cdc.gov/niosh/topics/ohl/

3. http://www.hse.gov.uk/research/rrpdf/rr604.pdf

This article originally appeared in the October 2016 issue of Occupational Health & Safety.