New Standards, Enforcement Working, OSHA Chief Says

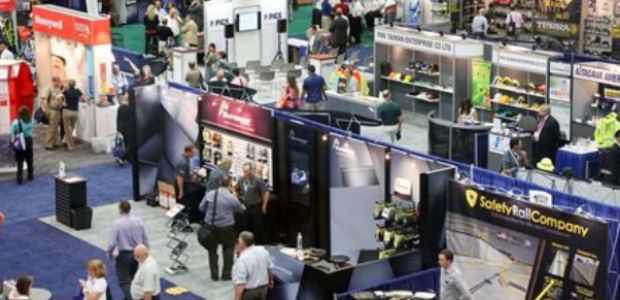

OSHA chief Dr. David Michaels discussed several enforcement initiatives of his agency May 24 at the AIHce 2016 conference

BALTIMORE -- OSHA chief Dr. David Michaels discussed several enforcement initiatives of his agency May 24 at the AIHce 2016 conference, including the new injury tracking regulation and the mandate to report amputations and hospitalizations of injured workers. During the first year the severe injury rule was in effect, OSHA received about 10,000 reports but did not inspect most of those workplaces, he said, choosing instead to call the employers and send them an accident investigation form. That has been very successful, he explained, and has brought some very severe cases to OSHA's attention at the agency otherwise would not have know about.

Michaels also supported the idea of vacating some outdated PELs where the limit that is in place is actually allowing unsafe exposures, he said, citing n-hexane as an example. Its PEL is 500, which is clearly too high to be safe, he said.

NIOSH's Dr. John Howard said nanotechnology is a good example of an area where his agency looks to international standards and beyond the current OSHA PELs for guidance. Both men agreed that he current model, proceeding chemical by chemical to write exposure limits is not useful in the 21st century, and both expressed support for the control banding approach, where limits are set for a group of similar substances of concern.

Howard urged the assembled industrial hygienists to participate in developing consensus standards, noting that the federal government's scientists are encouraged to do this.

Michaels said the injury tracking rule his agency recently issued and its revised silica exposure limits will be effective. As OSHA prepares to receive 400,000 companies' injury data and post it online, he said that will lead to better safety performance, likening it to a system used by New York City to give restaurants letter grades for hygiene and food safety. "This works," Michaels said.