Safety Incentive Programs Work

The active use of the program by successful teams suggests that acknowledgement is critical to the success of these programs.

- By Jerry Laws

- Jun 01, 2015

Sean Roark, a Certified Professional Incentive Manager, is the executive vice president of PromoPros/IncentPros Inc., in the Houston suburb of Spring, Texas. I asked him about his work with clients on the Gulf Coast, where the plunge in oil prices caused some energy companies to lay off thousands of workers during the past year. I asked how often CFOs or executives tell him something like this: "We need to cut costs, and cutting our safety incentive program is a quick fix. I'll worry about the consequences somewhere down the road."

"That comment typically comes to me anecdotally from the safety professional I'm dealing with; I usually don't end up in the office with the CFO. Some of the companies I'm dealing with are dealing in billions of dollars, and our entire safety incentive budget is pretty much a rounding error for those folks," Roark said. "What does happen is, somebody comes up and says, ‘We're going to cut 10 percent across the board, everybody's budget has to cut 10 percent.' And that did happen at a client. . . . They were saying, 'We're not going to cut out the Halon fire suppression system. We're not going to cut out the shelter-in-place bunkers. Why don't we just cut this safety incentive program? Because we have a great safety record.' Fortunately, my introspective safety guy said, 'Keep in mind, part of the reason we've got a great safety record is that since we started using this safety incentive program several years ago, we've seen a big uptick in safety performance.'"

Roark said he also discussed the downsides to using cash as a reward while talking recently with the safety manager of a manufacturing company, only to have the manager tell him, "Well, that's really not my pay grade. People above me are making that decision."

"It makes it very difficult when I talk with someone who doesn't take ownership of the [incentive] program," he explained. "They're seeing it as a budget matter and not as a really, really smart program that not only takes care of their employees, but pays for itself."

Paraphrasing Henry Ford, he said someone who cuts a safety incentive program to save money is like a person who stops a clock to save time. The analogy applies because a properly designed, implemented, and managed safety incentive will virtually always create a safer work environment, so that the value of savings in lost time, medical bills, damages, and related costs will be far greater than the cost of the incentive program. Eliminating a safety incentive program will almost always cost more than it saves, with incremental costs snowballing in future years, Roark said.

Cash is the number one answer to the question, "What do you want as a reward?" And companies already have a delivery mechanism (payroll) in place to deliver it. But while cash is frequently considered a simpler, more desirable reward, it is a) more expensive and b) less effective, he said.

Roark said the tax experts of one client determined that the custom design elements for the safety incentive program he was recommending would make it eligible for preferred tax treatment under IRS 274 (j). The net effect of this was that the client would get the purchasing effect from this program that would cost the client about twice as much in cash flow if using a cash-based reward program, because the IRS would require that it be treated as compensation. The loss of this preferential tax treatment in a non-qualified program (one of the criteria is that the program cannot use cash or cash equivalents as a reward) required that the client would have to gross up the reward to give the same net amount to the employee, then pay all related employer tax burdens on that grossed-up payment. This client's financial advisors calculated that a comparable cash-paid-out incentive program would cost them about $1,050,000, compared to the approximately $600,000 cost of their IRS 274 (j)-compliant program that year. They also recognized that a cash-based program would produce worse results, due to the fact that studies show that using cash to affect behavioral outcomes is less than half as effective as merchandise.

How More Active Programs Improve Safety

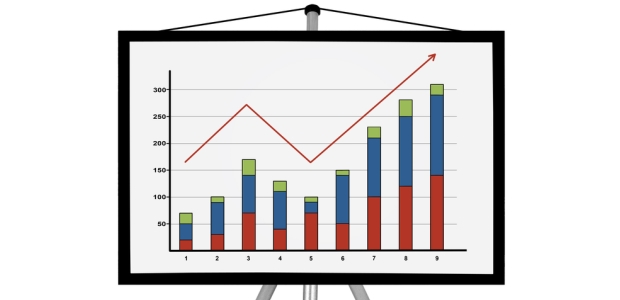

As an example of the efficacy of a well-planned and managed safety incentive program, Roark pointed to a study of results from a program that had been in operation for almost a decade, which compared the active use of performance-based elements of the program to outcome-based components (all were OSHA-compliant). The study showed that the more actively a location participated in recognizing performance-based criteria (in this program, by distributing points for achieving specific metrics and best practices), the better they achieved in outcome-based criteria, which measured overall compliance with Standard Operating Procedures and also as compared to overall review of safety logbooks. Program results demonstrated that the more that the program is used and promoted by individual teams, the better the safety record of those specific locations. Here's how the program worked:

- Safety Vouchers added points to a participant’s account, which can then be redeemed for merchandise. They were issued in recognition of an employee performing a best practice that is "above and beyond" his or her job description, such as volunteering to assist in a safety meeting, identifying a potential hazard, or some other best practice. This was considered a leading indicator because a voucher's being awarded was not associated with any type of outcome.

- Quarterly Team Bonus points were awarded quarterly to teams that achieved very good performance during a period, measured by high safety records and minimal incidents or write-ups for non-compliance with the SOPs. This was considered a lagging indicator because the bonus is outcome-based on results that have already occurred when the award was presented. The study of this program compared the average number of vouchers issued to each employee on a particular team with the number of quarters the employees on that team received a quarterly bonus (indicating a very safe quarter). The following statistic was compiled for a three year period from Jan. 1, 2011, to Dec. 31, 2013 that involved 36 "safety teams" of program participants.

Results: The teams that were in the highest 25 percent of quantity of vouchers awarded (per active participant) received 100 percent of their quarterly outcome-based bonuses. The teams that were in the second 25 percent of quantity of vouchers awarded (per active participant) received 95 percent of their quarterly bonuses. The teams that were in the bottom 50 percent of quantity of vouchers awarded (per active participant) received 61.7 percent of their quarterly bonuses.

The differences in the performance-based voucher distribution and the (lagging indicator) outcome-based team bonuses is a clear indication of the effectiveness of the program. In less successful teams, experience tells us that it's not that the participants weren't participating or reporting issues, but that they were not being recognized and appreciated for doing so, Roark said. Where the program was actively used by managers distributing vouchers, there is a demonstrable increase in hard safety statistics. Using recently assimilated data from 2014, the findings of the previous three years seem to be borne out (in fact, is more pronounced) for the one year period from Jan. 1, 2014, to Dec. 31, 2014:

- The teams that were in the highest 25 percent of quantity of vouchers awarded received 100 percent (all four out of four) of their 2014 quarterly bonuses.

- The teams that were in the second 25 percent of quantity of vouchers awarded received 82.5 percent (just over three out of four) of their 2014 quarterly bonuses.

- The teams that were in the bottom 50percent of quantity of vouchers awarded received 55 percent (just over two out of four) of their 2014 quarterly bonuses.

Roark said the results suggest three conclusions. First, the safety incentive program works—when it is implemented by field management according to design standards, a consistent accident-free record has been demonstrated over a four-year analysis of the results. Second, looking at year-to-year trends, the program becomes progressively more effective in successive years of active engagement. Finally, the active use of the program by successful teams suggests that acknowledgement is critical to the success of these programs. When someone does a positive act for the common good that is "above and beyond" his job description, failing to aggressively acknowledge that act by a manager lessens the chance that such positive acts will become an adopted standard behavior in the culture of that location, he said.

This article originally appeared in the June 2015 issue of Occupational Health & Safety.