Oregon OSHA Posts Respiratory Program Guide for Small Businesses

Breathe Right! is a booklet that explains the process of selecting and maintaining a respiratory protection program, from hazard analysis to voluntary use.

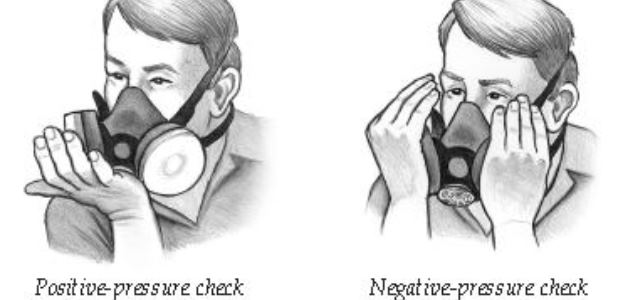

A new publication titled Breathe Right! from Oregon OSHA is an easily understood guide to developing a respiratory protection program for owners and managers of small businesses. It covers Assigned Protection Factors and different types of respiratory hazards, fit tests, seal checks, respirator cleaning and disinfection, voluntary use, employee training, and respirator use by bearded workers.

It recommends that, after evaluating employees' exposures to each respiratory hazard, managers should then eliminate the hazards or lower employees' exposures to safe levels. "You can't just hand out respirators and expect employees to use them properly," it states. "If respirators are necessary to protect your employees, you must have a written program that describes how you will accomplish the following:

- "Select appropriate respirators for employees.

- Conduct medical evaluations for employees who use respirators.

- Fit test employees who use tight-fitting respirators.

- Ensure employees use respirators correctly during regular activities and during emergencies.

- Ensure respirators are clean and properly maintained.

- Ensure air quality in atmosphere-supplying respirators.

- Train employees to protect themselves from respiratory hazards.

- Evaluate your program's effectiveness."

The guides notes that an effective program ensures that employees are medically able to use respirators, that their respirators fit properly, and that they know how to use and care for them.