Guarding Injury Prompts OR-OSHA Fine

Bright Oaks Meat, Inc. was fined $7,850 after the worker's right hand was severely injured by a meat tenderizing machine in August 2013, according to Oregon OSHA.

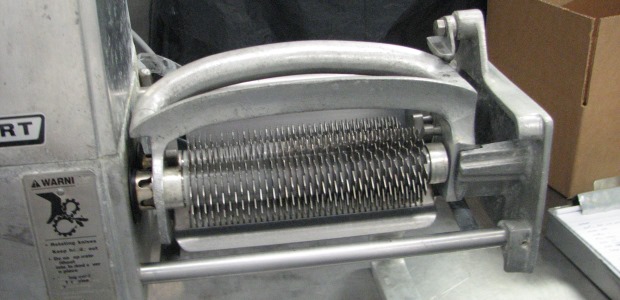

The Oregon Occupational Safety and Health Division (Oregon OSHA) has fined Bright Oaks Meat, Inc. $7,850 because an employee was seriously injured when feeding an unguarded meat tenderizing machine. The fine accompanied a willful violation after the agency inspected the facility Aug. 12, 2013, nine days after her injury occurred.

She was wearing gloves and feeding meat into the machine, when her right hand was pulled into the blades. "Two fingers were severely fractured and cuts to her hand required 60 stitches. The report also showed the worker, who had been employed at Bright Oaks Meat for about a year, never used the machine with the guard," according to the agency.

It cited the company for not guarding the meat tenderizing machine, failing to report an overnight hospitalization to Oregon OSHA within 24 hours, and lack of a safety committee. "This employer consciously neglected a safety measure that could have prevented the injury," said Oregon OSHA Administrator Michael Wood. "There is no reason for an employer to decide it can simply disregard the rules."

OR-OSHA said its inspection showed the guard had been missing for two years before the injury. While a willful violation can bring a $70,000 penalty, OR-OSHA reduced the penalty because the business is a small employer and the violation was unlikely to cause the death of a worker.