NHCA Agrees More Time Needed to Retest Hearing Protectors

The National Hearing Conservation Association's comments on the EPA proposal recommend simpler labels, 42 months to retest and relabel protectors, and requiring a statement on the labels saying individual quantitative fit testing is the only way to estimate a user's attenuation.

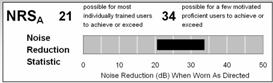

The National Hearing Conservation Association has submitted comments to EPA about its proposed update of the regulation governing how hearing protection devices are tested and labeled. NHCA makes eight recommendations in its comments, asking that EPA specify simpler labels, based label values on ANSI S12.6-2008 Method B rather than Method A, and extend the proposed window for retesting and relabeling protectors from 30 to 42 months, the latter divided into a 24-month interim period when only products with the current labels are sold and an 18-month transition period when products could be sold with old or new labels. Once the 18 months had ended, only products with the new labels could be sold.

"Noise-induced hearing loss is a progressive and permanent disease which has a pervasive impact on people's lives. While noise control efforts are the preferred way to reduce occupational and community noise exposures and prevent hearing loss, many Americans depend on ear plugs and ear muffs to protect their hearing," said NHCA President Rick Neitzel, Ph.D., CIH. "The current Noise Reduction Rating methodology is obsolete and needs to be updated to reflect a more real-world approach to hearing conservation. Also, the new NRR needs to account for the fact hearing protectors are used both in the workplace, where users should be trained on how to protect their hearing and how to wear protectors correctly, as well as recreationally, where users are likely to be less knowledgeable about how to best protect their hearing."

"Noise-induced hearing loss is a progressive and permanent disease which has a pervasive impact on people's lives. While noise control efforts are the preferred way to reduce occupational and community noise exposures and prevent hearing loss, many Americans depend on ear plugs and ear muffs to protect their hearing," said NHCA President Rick Neitzel, Ph.D., CIH. "The current Noise Reduction Rating methodology is obsolete and needs to be updated to reflect a more real-world approach to hearing conservation. Also, the new NRR needs to account for the fact hearing protectors are used both in the workplace, where users should be trained on how to protect their hearing and how to wear protectors correctly, as well as recreationally, where users are likely to be less knowledgeable about how to best protect their hearing."

The association's letter is posted here. NHCA asks that EPA require a statement on the labels saying individual quantitative fit testing is the only way to estimate a user's attenuation. And it asks that labels no longer emphasize user "motivation" as a reason some might achieve greater attenuation than others. "Many factors can contribute to attenuation achieved, including physiology, condition of the device, etc.," the letter states.

The letter recommends that label values be based on the ANSI S12.6-2008 Method B protocol, which accounts for hearing protectors fitted by trained and naïve users alike. "The EPA should also ensure that the de-rating of labeled values is eliminated from the new NRR scheme. Over the years, de-ratings have created a great deal of uncertainty and confusion that has diminished the effectiveness of hearing loss prevention programs in the United States," Neitzel said. "The required labels should be simplified, made more symbol-based, and provided in multiple languages to ensure that their correct use is clear for all users. Supporting information, such as the performance of the protector at specific test frequencies, should be provided online, as a packaged insert or upon request from the manufacturer in order to further simplify package labeling."

The letter recommends that label values be based on the ANSI S12.6-2008 Method B protocol, which accounts for hearing protectors fitted by trained and naïve users alike. "The EPA should also ensure that the de-rating of labeled values is eliminated from the new NRR scheme. Over the years, de-ratings have created a great deal of uncertainty and confusion that has diminished the effectiveness of hearing loss prevention programs in the United States," Neitzel said. "The required labels should be simplified, made more symbol-based, and provided in multiple languages to ensure that their correct use is clear for all users. Supporting information, such as the performance of the protector at specific test frequencies, should be provided online, as a packaged insert or upon request from the manufacturer in order to further simplify package labeling."