Scientists Devise New Method of Finding Trapped Miners

University of Utah scientists devised a new way to find miners trapped by cave-ins. The method involves installing iron plates and sledgehammers at regular intervals inside mines, and sensitive listening devices on the ground overhead.

"We developed an approach to find the location of trapped miners inside a collapsed mine, regardless of noise from the environment around the mine," said Sherif Hanafy, an adjunct associate professor of geology and geophysics at the University of Utah and first author of a study demonstrating the technique.

The new study was published in this month's issue of The Leading Edge, a journal of the Society of Exploration Geophysicists.

The method records "seismic 'fingerprints' generated by a trapped miner banging on the mine wall, and uses those fingerprints to locate him. Each different location in the mine that is banged has a unique fingerprint," said Gerard Schuster, a professor of geology and geophysics at the University of Utah and the study's senior author.

"We hope to make it easier to find out if miners are alive after a collapse and, if they are alive, where they are located," he added. "It's not guaranteed to work every time, but looks promising from the tests we did. This is not rocket science; it's rock science."

The researchers and a number of Utah graduate students tested the system twice. One test was in a utility tunnel beneath the University of Utah campus. The other test was in much deeper tunnels in an abandoned copper mine near Tucson, Ariz.

Schuster says more testing is needed to make sure the method will work in deeper mines, such as coal mines, which can be a few thousand feet deep. He said that while the method was tested only in horizontal mines tunnels, it also should work in vertical shafts.

The system would be installed in stages as a mine is excavated. Components include:

- Inside mine tunnels, "base stations" are built every 10 yards to every few hundred yards, depending on each tunnel's length. At each station, a 4-inch-by-4-inch iron plate is bolted to the wall, and a sledgehammer is placed near each plate.

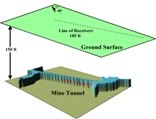

- On the surface, cables are strung along the ground above each tunnel or shaft, and "geophones" are spaced at regular intervals along the cables. Geophones listen for seismic waves created when miners use the sledgehammer to bang on an iron plate.

- Once the system is installed, and as the mine expands and base stations are added, each base station is "calibrated," meaning its plate is whacked and the seismic waves are recorded by the geophones overhead. Each base station has a distinct seismic wave "fingerprint." If miners are trapped and bang the metal plate at the nearest base station, the resulting seismic recording will allow rescuers to determine precisely which base station plate was thumped, and thus where the miners are located.

Listening stations would record the seismic wave pattern from each geophone. The collective pattern would be compared--by a computer--with the calibration seismograph recordings collected prior to the collapse. A match identifies the base station or stations where survivors have gathered and walloped the iron plate.

Along with Hanafy and Schuster, the study's coauthors are Weiping Cao, a doctoral student in geology and geophysics, and M.K. "Kim" McCarter, a professor of mining engineering at the University of Utah. In addition to his Utah affiliation, Hanafy is an associate professor of geophysics at Cairo University in Egypt.