We are living in unprecedented times. Anxieties are high, and questions abound. That’s why our PPE experts have put together a new resource, containing answers to all of your safety-related COVID-19 questions, in a tidy downloadable PDF.

Sponsored by Bulwark FR®

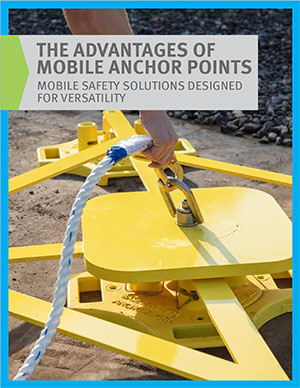

Fall safety remains a number one concern in both the general and construction industries. As building functionality and design evolves, it’s become more complex: with varying job types and work sites, traditional solutions like guardrails don’t always fit the bill. For various reasons, harnesses and lanyards can be the most economically or logistically suitable choice. An OSHA-certified anchor point is a critical component of any harness and lanyard system. Usually, they’re installed on the roof (or elsewhere on your building), ready to connect to a lifeline or lanyard, which then connects to a harness to prevent its wearer from falling. But a fixed anchor point doesn’t always allow for the versatility that brought you to choosing a harness system to begin with.

Sponsored by BlueWater by Tractel

Lab coats have been used for decades, but they have typically been made from cotton or polyester/cotton blends, with the primary purpose of keeping foreign materials off the clothing under the coat. Two of the most common lab accidents involve chemicals and fire/explosions, and common lab coats don’t provide protection from either hazard. This technical brief outlines the importance of chemical splash protection (CP) clothing for laboratories.

Sponsored by Bulwark CP

Safety professionals are accustomed to leading worker safety initiatives across work sites that can be separated by tens, hundreds and even thousands of miles. The COVID-19 pandemic introduced new safety management challenges, however, as many safety professionals themselves were asked to work off-site while their essential worker colleagues continued to report to the worksite.

Sponsored by Safety io, LLC

Today, safety professionals face a host of challenges. Generational turnover, technology proliferation, regulatory changes, budget constraints, and other factors create distractions, interruptions, and frustration. On top of it all, these same professionals are under significant pressure from their organizations to achieve even more aggressive safety goals.

Sponsored by Safety io, LLC

One of the hardest task a company faces when initiating a safety culture – or even a safety policy – is ensuring buy-in from throughout the organization. One false step and you’ll ensure failure before you even get started. Know how to sell safety and get buy-in from everyone.

Sponsored by SmartDrive Systems, Inc

It’s important to equip workers in the oil and gas and utility industries with the proper flame resistant and arc-rated (FR/AR) rainwear. This tech sheet outlines what to look for when selecting FR/AR rainwear.

Sponsored by Bulwark FR®

This white paper helps to clarify this complexity, so you can better navigate the standards and better ensure the safety of your employees.

Sponsored by Red Wing Shoe Company

While most discussions about arc flash involve the calculation methods and associated personal protective equipment (PPE), electricians have a number of ways to protect themselves and their gear, including arc- resistant equipment and remote actuation and racking systems that eliminate – rather than reduce – electrical arc-related dangers while providing quantifiable force and other preventive maintenance data that can help avoid future catastrophes.

Returning electrical equipment to service after a planned maintenance outage creates a unique set of hazards. Facility managers are under stringent time constraints when taking a system out of service, performing necessary maintenance tasks (as well as making unanticipated repairs), and returning the system to service. Common, real-world factors may place workers at great risk as the system is returned to service. This paper seeks to identify those factors and present logical and practical ways to lessen or eliminate risks.