Updated Standards Help Demystify Fall Protection Product Selection

Heightened federal oversight on falls means employers should make sure they’re familiar with fall protection standards and that each worker is using the right type of harness for their particular application.

- By Diana Jones

- Aug 01, 2023

Falls remain the leading cause of fatalities and serious injuries in all industries, but especially in construction, as OSHA noted in announcing its new National Emphasis Program (NEP) on falls in the workplace back in May.

According to U.S. Bureau of Labor Statistics data, slips/trips/falls accounted for nearly 16.5 percent (6,680) of the 40,531 workplace fatalities in all industries from 2014 through 2021, most were “falls to lower level,” which accounted for over 13 percent (5,369) of fatalities during that period.

“Falls to lower level” accounted for 32 percent (2,480) of the 7,861 construction fatalities during this period.

OSHA indicated that its NEP will lead to both construction and non-construction inspections. Non-construction inspections will target rooftop mechanical work/maintenance, utility line work/maintenance (electrical, cable), arborist/tree trimming, holiday light installation, road sign maintenance/billboards, power washing buildings (not connected to painting), gutter cleaning, chimney cleaning, window cleaning, and communication towers.

OSHA is serious about cutting what it called “unprotected worker exposures to fall-related hazards in all industries that can result in serious injuries and deaths.” Employers should anticipate a combination of enforcement, outreach, and compliance assistance—especially at construction worksites, where the majority of fatal falls to lower levels have occurred.

The ABCs of Fall Protection

Heightened federal oversight on falls means employers should make sure they’re familiar with fall protection standards and that each worker is using the right type of harness for their particular application.

There are three essential elements of a fall protection system. At ISEA we call them the ABCs of fall protection:

- Anchorage/Anchorage Connector: Anchorage is commonly referred to as a tie-off point (such as an I-beam); an anchorage connector (such as a cross-arm strap) is used to join the connecting device to the anchorage.

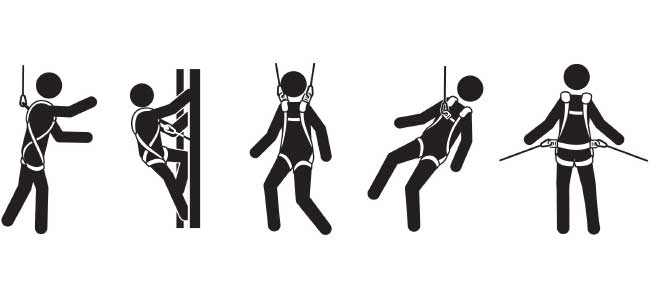

- Body Wear: This is the personal protection equipment (such as a full body harness) worn by the worker.

- Connecting Device: This is the critical link that joins the body wear to the anchorage/ anchorage connector (for example, a shock-absorbing lanyard or retractable lifeline).

Full Body Harnesses

The full body harness is the safest body wear solution to use when working from heights, advised Rob Willis, Global Product Group Director Industrial PPE & FP Systems, MSA Safety, and chair of the ANSI/ASSP Z359.11 subcommittee. It offers the best protection from coming out of the harness in a head-first fall, and it helps distribute the body’s load across all parts of the harness.

While full body harnesses all look similar, they come in a variety of materials and have important differences depending on the wearer’s particular tasks and work environment. For example, a welder would likely need a harness that incorporates KEVLAR® for flame resistance, while confined-space harnesses need multiple rescue points.

Full body harnesses are covered by the ANSI/ASSP Z359.11-2021 Safety Requirements for Full Body Harnesses standard. (ANSI/ASSP Z359.11-2021 recently updated the testing requirements for full body harnesses, but testing requirements apply mainly to manufacturers, not to employers.)

The standard explains different materials used in a full body harness, the parts of the harness, such as attachment points (like back, front, and hip D rings), their function, and how they vary depending on their intended application. The position of the worker’s body while performing certain tasks also has to be taken into account when choosing the appropriate full body harness. The most recent revision of the standard now includes standard iconography in the label pack. These labels show the purpose of each d-ring connection on the harness.

As many know, Z359 has 18 chapters. Each is its own standard. Taken together, all the standards are known as the Fall Protection Code.

The chapter, or standard, on Self-Retracting Lanyards (SRLs), ANSI/ISEA Z359.14-2021, Safety Requirements for Self-Retracting Devices for Personal Fall Arrest and Rescue Systems, was recently updated and employers, safety managers and others should take notice!

New SRL requirements

The updates to ANSI/ASSP Z359.14-2021 take effect in August 2023. The update created two different classes and specified their intended uses. The recent updates also introduced new requirements for SRLs’ allowed average arresting force (AAF), increasing from 900 lbs. (4 kN) to 1,350 lbs. (6 kN). (Note: Some self-retracting lifeline models may have an AAF of less than 1,350 lbs., yet still meet the ANSI/ASSP Z359.14-2021 standard.)

“It is necessary to confirm that the strength of your anchorage is sufficient for the increased values in AAF,” said Willis. “Always check the product label for the actual AAF indicated on the self-retracting lifeline, to validate use with appropriate anchorages.”

Willis explained that while safety professionals do need a good working knowledge of the standard, there’s no need to overly complicate the fall-protection product selection process. Manufacturers and suppliers offer very good expert insight when an employer describes the specific application and the work an employee will be performing.

“Of course, you want to make sure you understand the limitations of each product,” said Willis. “But those representatives can demystify the process and help guide you through the features a particular full body harness should have for a particular situation.”

Summer is arguably the busiest season for construction and other work at heights. For employers who haven’t yet made fall protection a top priority, there’s no time like the present to ensure worker safety. Don’t wait for an OSHA inspection—or a tragedy to happen—before acting.

The International Safety Equipment Association (ISEA) offers a comprehensive set of information resources about fall protection online at safetyequipment.org/worker_protections/fall-protection.

This article originally appeared in the August 1, 2023 issue of Occupational Health & Safety.