Facing a Combustible Dust Hazard? Consider These Questions.

Combustible dust poses serious risks—even from seemingly low-threat dusts.

- By Scott Francis

- Oct 03, 2022

Amid today’s workplace safety landscape, combustible dust is a conundrum. Dust in the workplace is unavoidable; yet, managing dust is much more than a routine housekeeping consideration. Anything from sugar to metal to rubber can produce dust, and in manufacturing settings, these dust particles can pose serious hazard risks. These risks span not only fire and flash fire but also blast and explosion scenarios. The combustible dust hazard is a multi-faceted situation with many variables and outcomes.

If your workplace contends with dust particles, ask yourself these three questions to better understand the hazards surrounding combustible dust incidents.

1. Why is Addressing a Combustible Dust Hazard Important?

Aside from the regulatory and duty of care responsibilities an employer faces, combustible dust poses serious risks—even from seemingly low-threat dusts.

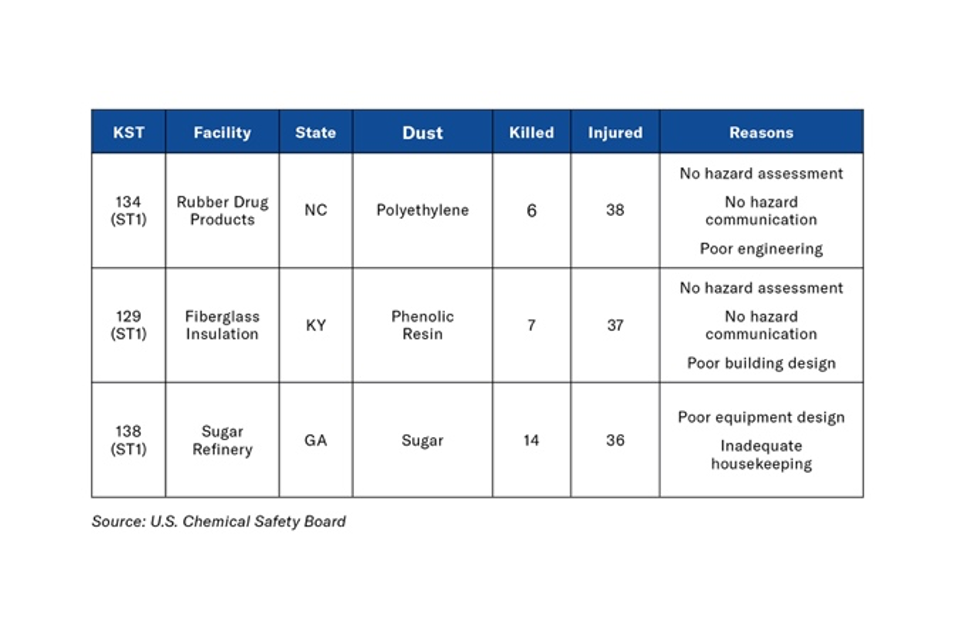

Take a look at the following incident examples.

A dust’s KST value, determined experimentally in a lab, is the deflagration index measuring the specific dust cloud’s explosibility. These three incidents were caused by dusts with a KST value of less than 200 bar-m/sec, which is considered “weak explosion” dusts. This misnomer—a weak explosion—still results in very real loss. These three incidents alone accounted for 27 fatalities, 111 injuries and millions of dollars in property loss, and all three incidents have a human error precursor as a root cause. These human error precursors, such as lack of knowledge or complacency, led to things like hazard assessment avoidance and inadequate housekeeping, which contributed to the resulting explosion.

The takeaway here is that any dust with a KST classification other than KST=0 must be accounted for with a comprehensive combustible dust hazard mitigation plan.

2. How Do You Assess Your Combustible Dust Hazard?

NFPA 652, the Standard on the Fundamentals of Combustible Dust, is the on-ramp standard to addressing combustible dust hazards as part of the NFPA standards suite. It shares fundamental safety principles applicable to all combustible dusts. Other NFPA standards, applicable to specific industries or commodities, contain requirements in addition to NFPA 652. In the typical application of the standards, where a Dust Hazard Analysis (DHA) reveals potential fire, flash fire or explosion hazards, the DHA outlines preventative and protective safeguards to put in place.

Much like any hazard, a series of administrative and engineering risk controls form the foundation of a site’s protection plan. These controls work together to limit the dust from igniting, by implementing thorough housekeeping protocols, reducing the oxidant concentrations, controlling credible ignition sources and mitigating the incident’s repercussions should an explosion happen.

3. Why is PPE Important in a Combustible Dust Scenario?

We often discuss how PPE forms a final layer of defense against short-term thermal events. Should all other measures and controls fail, PPE, especially when it’s flame-resistant (FR) and arc-rated (AR), helps curtail the severity of resulting injuries when these incidents occur.

Combustible dusts pose both a thermal hazard and an explosion hazard. While PPE will be unable to mitigate blast injuries, it can and will provide a measure of protection against resulting fire and flash fire injuries.

Take a look at the case study table. Notice the larger number of injuries as compared to fatalities. FR garments likely could have reduced the numerous injuries and may have lessened the injury severity that led to fatalities. FR PPE was not used in these past cases, even though it is required by governing regulations. NFPA 652 now calls out the need for PPE in combustible dust hazard areas, and OSHA has stepped up its inspections of combustible dust generating facilities via the National Emphasis Program and enforcement of PPE implementation through CFR 1910.132.

This article originally appeared in the October 1, 2022 issue of Occupational Health & Safety.