Far Too Many Fatal Falls

The latest BLS CFOI data showed 747 construction trades workers died in 2017, and that fatal falls were at their highest level in the 26-year history of the Census of Fatal Occupational Injuries.

- By Jerry Laws

- Mar 01, 2019

Some welcome news at the end of 2018 came from the federal Bureau of Labor Statistics, which announced that the U.S. fatal work injury rate dropped slightly in 2017. A total of 5,147 fatal work injuries were recorded in the United States in 2017, down slightly from the 5,190 fatal injuries reported in 2016, the U.S. Bureau of Labor Statistics reported Dec. 18. BLS reported that the fatal injury rate decreased to 3.5 per 100,000 full-time equivalent workers from 3.6 in 2016.

But then came the bad news: Fatal falls were at their highest level in the 26-year history of the Census of Fatal Occupational Injuries (CFOI) and accounted for 887 workers' deaths, according to BLS, which also reported Dec. 18 that fatal occupational injuries involving confined spaces rose 15 percent to 166 in 2017 from 144 in 2016.

The data showed 747 construction trades workers died in 2017, representing 14.5 percent of the total fatal work injuries during the year.

The 887 fatal occupational falls—up from 849 in 2016—represented an alarming 17 percent of the total worker deaths in 2017, according to the CFOI.

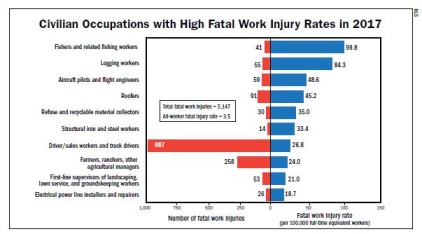

The agency identified 10 civilian occupations with high fatal work injury rates during 2017. The list included roofers, structural iron and steel workers, and electrical power line installers and repairers. All 10 had rates that year at least five times higher than the 2017 rates for all workers of 3.5 per 100,000 full-time equivalent workers:

"This level of worker safety and health is not acceptable," said ASSP President Rixio Medina, CSP, CPP, after the BLS report. "There needs to be greater energy and a stronger national focus on preventing serious injuries and fatalities on the job. Most of these incidents are preventable, and they are occurring far too often in every industry.

"We will continue to push for greater education and widespread improvement through a multi-stakeholder approach that must involve government agencies, business leaders, advocacy groups, labor unions and professional associations," Medina continued. "Significant change is needed in workplace safety cultures to better protect workers and ensure that they return home to their families every day. It's really about bringing best practices into the spotlight at all companies in every industry, such as prevention through design and risk management approaches. We believe the proper implementation of a safety and health management system can help protect workers and improve a company’s bottom line. Then everybody wins."

Sixth Annual National Safety Stand-Down: May 6-10, 2019

The alarming fatality numbers shine a spotlight on this year's sixth annual National Safety Stand-Down to Prevent Falls in Construction1, which is coming up fast—it is set for May 6-10, 2019. An OSHA partnership with NIOSH, CPWR – The Center for Construction Research and Training, and the National Safety Council, the Stand-Down is a week-long outreach event encouraging construction industry employers and workers to pause during the workday to discuss fall hazards and how to prevent falls.

It has been embraced by the industry: The partner organizations reported in 2018 that during the previous four years, thousands of companies had participated in the National Safety Stand-Down, reaching some 7.5 million employees across the United States and internationally through more than 130 public events and thousands of private stand-downs per year.

The journal Annals of Work Exposures and Health published an important article2 by four CPWR authors, "Construction Safety and Health in the USA: Lessons from a Decade of Turmoil," in September 2018. The authors (Knut Ringen, Xiuwen Sue Dong, Linda M. Goldenhar, and Christine T. Cain) discuss trends in U.S. construction industry fatalities from 2003-2015, reporting that they dropped to an all-time low—both the rate and the absolute number of fatal injuries—during 2010-2011 because of the recession starting in 2008 that sharply reduced construction activity. By 2016-2017, the industry was back to full employment, new employers and new workers entered the industry, and fatalities increased, they write.

Falls from height cause more than one-third of U.S. construction deaths. Fatal falls in construction had fallen to a low of 256 in 2010 but rose to 353 in 2015, according to a chart included in their article. They point out that, over a construction employee's working life that ended around 2010, the risk of fatal injuries was approximately one death per 200 FTE and for non-fatal injuries resulting in days away from work, the adjusted lifetime risk was approximately 78 per 100 FTEs. "However, those risks are not distributed randomly," they write. "As the CPWR surveillance results show, they are disproportionately high among smaller employers, and also among employers who employ primarily immigrant workers." Such employers are less likely than larger employers to have even basic health and safety procedures in place.

"The composite rate for all traumatic injuries was lower in 2015 than in 2003, even though it increased during 2012-2015. However, this was not the case for fatal falls," the article's conclusion states. "Because falls account for such a large proportion of all deaths, they disproportionately affected the composite trend in the last decade. If we ignored falls, the industry fared well. If we focused solely on falls, it was as if the industry had made no progress in prevention in that decade. Progress had been made, but progress had also been lost."

The authors conclude that New York City—with intensified inspections of smaller and less well capitalized construction projects, as well as a 2017 mandate requiring construction safety training—shows there are ways to address the problem. Permitting, licensing, and criminal prosecution may be powerful tools for promoting safety by requiring that only qualified employers and workers are in the industry, they write.

OSHA's Fall Prevention Training Guide for Employers

OSHA's Fall Prevention Training Guide,3 although it is dated 2014, offers several 5-10 minute toolbox talks that employers can use to train workers on fall protection and prevention, fact sheets in English and Spanish, and bilingual booklet on ladder safety. The first toolbox talk in the document concerns ladder safety—an especially important topic in March.

The guide's advice for trainers section recommends doing these things to get workers actively involved in the safety meetings:

- Ask questions instead of simply giving them information. After you ask a question, wait a short time to let people think, then call on volunteers to answer.

- Ask about personal experiences, which can help the group see how the topic is relevant to them. You could ask: "Has anyone here fallen off a ladder? What happened?"

- Make sure everyone has a chance to talk, but if a crew member is talking too much, invite someone else to speak.

- Never make fun of anyone or put anyone down, especially for asking questions.

- Don't fake it. If you don't know the answer to a question, do not guess. Write it down and promise to get back to the questioner.

- Stick to the topic. If questions or comments move too far from the topic, tell them their concerns can be addressed later, either privately or in a future safety meeting.

The second toolbox talk concerns scaffolding safety. It covers designing, using, and maintaining scaffolding once it has been erected.

Toolbox talk three is about safe roofing work. It includes typical fall hazards (floor openings, unprotected leading edge work, skylights, etc.), the elements of personal fall arrest systems and the need for workers to inspect theirs before each use, and the use of guardrails, netting, and other protection systems.

Workers are to be trained on hazard recognition and on the OSHA fall protection standard.

References

1. https://www.osha.gov/StopFallsStandDown/

2. https://academic.oup.com/annweh/article/62/Supplement_1/S25/5096686

3. https://www.cpwr.com/sites/default/files/publications/KF2018-lessons-from-a-decade.pdf and https://www.osha.gov/Publications/OSHA3666.pdf

This article originally appeared in the March 2019 issue of Occupational Health & Safety.