Winter is Coming and Bringing Workplace Hazards—Are You Ready?

Add in two backups in case of a widespread disaster. Many companies have an emergency call back, but if there is widespread power or cell outage due to winter events, what is the backup?

It was a long brutally hot summer—and the crisp change toward winter is welcomed by many. As the pleasantly dipping temperatures head to the "brrrrr" stage, as Safety, are you preparing your facility and workers (and management) for the different hazards associated with the colder weather? Have you planned ahead well?

Cooler temperatures bring along unique hazards, as well as those we see regularly. Slip-and-fall injuries rise dramatically, falls from elevations such as ice-glazed steps can see workers' compensation costs skyrocket with one bad storm. Snow removal from roofs or iced-over vents are certainly non-routine activities. Make a list of such potentials and discuss with your crew; you want the most fit and alert ready for each job before the need. If you anticipate special equipment needs, go ahead and set up the contacts now so that everyone knows their role.

- Awareness. It seems simple, but reminding employees about the season’s changing hazards can help. Include company expectations and how their not showing up impacts the team effort. Make sure those who are "mission critical" know this and fully understand their responsibility to come in if possible. Tell them when really hazardous weather events are expected and alter your company work hours if needed. Review your policies and update supervisors on them. Make sure you have a backup list for temps or other contractors if needed for a 24/7 operation.

- Diversity. If your workforce is multi-cultural and multilingual, make sure to show and tell in addition to printed materials. I have more than once had to explain/show what an ice scraper was used for on iced-over vehicles and how/when to use it for staff hired from tropical or desert countries. You may have to explain in detail over and over cold hazards, carbon monoxide poisoning, using candles/open flames, not to use space heaters, grills used inside, how to walk on ice-slick sidewalks if you can't get them cleared, etc. Handouts with pictures often help, too. In this case, safety is extended to homes because you need your workforce safe and back at work.

- Consider your workforce and what you produce. If the power is out, can you work? Is your primary workforce local? Or are they mostly young parents with children who will be out of school, requiring their care? Think back . . . what was the absenteeism rate for the last snow or ice storm? In some parts of the country, 4 inches of snow is not even a pause to everyday life; for others, though, it is a catastrophic event that closes everything for days because of downed power lines. Many cannot drive in such situations and will not venture out until it is clear. How do they dress? In high-heeled dress boots which are often made with slippery leather soles? Or do you have a more fragile workforce with an elderly population that are fearful to venture out. Each group has special needs you have to address.

- Timing for cold weather activities is important, too. I have worked in two places where the maintenance staff distributed sand/ice melt by 9 a.m. each day, but many staffers came in at 7 a.m. (As Safety, explaining the situation was not nearly as effective as the workers' comp bills for one broken wrist.) I volunteered at one workplace to come in early and distribute sand to the front and side doorways myself—it saved me more injury paperwork to manage. Management originally did not want to pay the $12 for sand. By the second winter storm, and thousands of dollars from falls, they were more eager to be proactive.

- Budget. Plan ahead for those employees who require cold weather gear such as gloves, hats, liners, glare protection, coats, etc. Then add extra to it for real crisis situations that may need heavy machinery to place employees on the roof or for clearing parking lots. Make sure you consider well ahead those winter weather safety needs and budget/order them long before needed. It may include food for those extra long shifts, emergency generators, transportation costs, specialty shoes/cleats, or contractors. High-hazard confined space or fall protection needs? Look back, then plan ahead.

- Emergency backup power and fire protection. In extremely cold or severe weather, do you have the extra fire protection needed if water freezes up? Are you ensuring fire watches and walk-throughs are happening and making sure space heaters are not used or used only with approval? Do you have emergency backup power? Has it been tested, and do personnel know how to activate it if it is not automatic (smaller operations). How about dead batteries on vehicles and lighting, including flashlights using batteries? Do you know what is subject to damage if it freezes? (Think of computer components, monitors, etc. Can you protect them from power surges due to ice-coated power lines?)

- Don’t add to the situation. Help employees adapt safely in cold weather situations. A great example was a young, enthusiastic safety officer who was advising others to use a "red drinking cup" to distribute ice melt or salt/sand (this was a health care environment). Can you think of a better way than to potentially poison someone thinking it is a drinking cup? In unusual circumstances especially, safety personnel have to slow down and do/say the correct things. We all want the employees to get the job done—safely. That includes protecting the public.

- Communication. Add in two backups in case of a widespread disaster. Many companies have an emergency call back, but if there is widespread power or cell outage due to winter events, what is the backup? One great reminder is to ensure all supervisors keep up to date with the policy and expectations for their staff and discuss this with them. Have a variety of contact features, including TV and radio broadcasts and drivers with heavy vehicles for transportation if needed (hospitals use this often), plus a set message for employees to call into, call back trees, etc. Use what works. Make sure everyone knows what to do. While cell phones are wonderful, often they can be compromised easily; in true disaster situations you may be able to text but not call; or have a set Facebook or other social media page at the ready.

- Appreciation. When the ordeal is all done and over, it is time for you and upper management to honestly thank those who went above and beyond what was expected to get the work done. Tell all of your employees how much you appreciate their efforts and show them with something such as a luncheon. Single out those who should be recognized the most first. You would be surprised how far a sincere handshake and thank you go in the workforce. (Because there will be a next time. . . . )

- Documentation. Don’t forget to document everything. If you have a spike in injuries, you will need to be able to explain what was happening to contribute to it. Such documentation helps with next year's budget planning, too, acquiring more staff for safety, larger budgets, etc. The winter crisis today will fade quickly in just a few months.

- Your COOP plan. Now is a great time to review your company COOP plan and refresh yourself on who does what. Make changes and requests based on potential need and "what if" justification. COOP plans help manage the worst-case situations, which is much better than needing and not having in a crisis or not knowing what to do, which is a helpless feeling. Include the ability to hire extra safety during a big situation and pull in some assistance, such as contractors, retired staff, etc. Have a list ahead of time—in a huge crisis you will need help, too.

As Safety, you are part of the company leadership. You have to plan for any business interruption and ensure both staff and company assets are safe and ready to continue operations in one form or another, often in spite of upper management. Every season has challenges. Winter can be hard to contain even in the best of times.

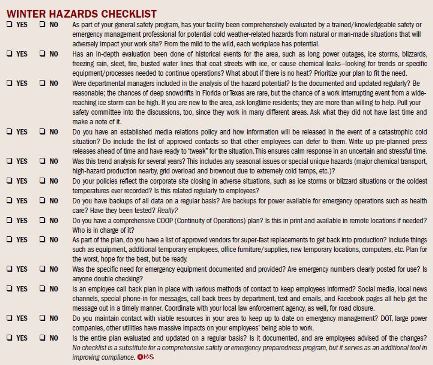

It is a balancing act. You want the work to continue, but in a catastrophic situation you may not be able to operate. You decide well in advance how you best protect your employees and keep the mission of the company moving forward and manage the media, too! Does your site or facility safety program consider all of the planned and unforeseen hazards to protect workers from potential small- and large-scale disasters? Do you have additional safeguards in place for planning and eliminating larger issues that will impact your corporate bottom line, such as physical destruction of the site? The following checklist may help you evaluate your program.

This article originally appeared in the October 2017 issue of Occupational Health & Safety.

About the Author

Linda J. Sherrard, MS, CSP, is Safety Consultant II with Central Prison Healthcare Complex, NCDPS in Raleigh, N.C., and is the former technical editor of OH&S.