Your Eyes Are Amazing—They Deserve Quality PPE

When vision is impaired, quality of life and the ability to work experience a drastic and unfortunate decline. Preventing eye injuries should be a top task on every safety professional's to-do list.

- By Mary Padron

- Jun 01, 2017

According to NIOSH, every day more than 2,000 workers in the United States suffer from an eye injury and require medical treatment. That's more than 700,000 Americans each year! Approximately one-third of those injuries require emergency room treatment and 100 of them result in one or more days away from work.

When Should Workers Wear Eye Protection?

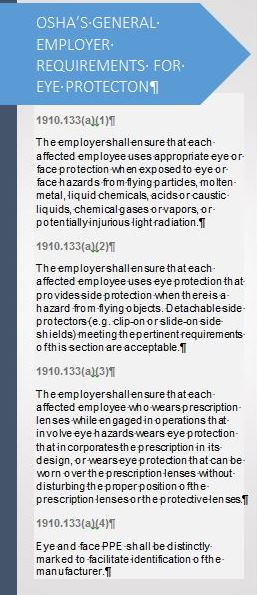

Any worker or bystander who is working in, near, or passing through eye risk areas should wear protective eyewear. Please see the sidebar about OSHA's general requirements for employers to provide eye protection.

The type of eye protection to specify depends on the hazards in the workplace. If the job site has flying objects, particles, or dust, safety glasses with side protection (side shields) must be worn. Workers who work with or near chemicals should wear goggles with indirect vents. If hazardous radiation is a risk, workers must wear special-purpose safety glasses, goggles, faceshields, or helmets designed for that task.

Common causes for eye injuries include:

- Flying objects from equipment operation (bits of metal, glass, wood, etc.)

- Chemical splash

- Tools

- Particles and dust

- Acids or caustic liquids

- Harmful radiation

- Falling objects when reaching for items on tall shelves

Three Things That Help to Prevent Eye Injuries

1. Understand and identify the safety risks at work.

Identify the work activities that could put your employees' or guests' eyes at risk. Risk is the probability that a person will be harmed if exposed to a hazard, such as the hazards listed above. Risks are usually rated:

- low for minimal risk

- medium for minor or serious risks that aren’t likely to occur

- high for unacceptable risks that are likely to occur

Organizations should always consider ways to eliminate or modify unacceptable vision risks.

Manufacturers often have product managers who specialize in specific protection categories, such as eye safety. These product managers, or product champions, often will consult with safety professionals to help them understand and identify the safety risks and dangers at their job site.

2. Control the hazard by elimination, engineering controls, administrative controls, or through the use of the appropriate PPE.

Elimination or substitution of the hazard is the most effective method for removing a hazard. For example, can I use a water-based chemical that is not harmful instead of a solvent-based chemical that could damage a worker’s vision? Unfortunately, elimination or substitution is often not possible or practical.

Engineering controls are another effective method for reducing worker exposure to hazards. They include designs or modifications to plants, warehouses, equipment, ventilation systems, and workstations to make these areas safer or more ergonomic.

Administrative controls change the way the work is done to achieve a safer outcome, including timing of work, policies, rules, work practices, operating procedures, etc.

Personal protective equipment provides protection against hazards. It should be used when other safety controls are not practical or be used in addition to other controls. For example, to help prevent eye injury, make sure your employees are wearing ANSI Z87+ impact resistant eyewear.

3. Choose safety glasses with the ANSI marking of "Z87+" for your workers.

ANSI/ISEA Z87.1-2015, American National Standard for Occupational and Educational Personal Eye and Face Protection Devices, sets forth criteria related to the general requirements, testing, permanent marking, selection, care, and use of protectors to minimize the occurrence and severity or prevention of injuries from such hazards as impact, non-ionizing radiation, and liquid splash exposures in occupational and educational environments, including, but not limited to, machinery operations, material welding and cutting, chemical handling, and assembly operations.

Certain hazardous exposures are not covered in this standard. These include, but are not limited to: bloodborne pathogens, X-rays, high energy particulate radiation, microwaves, radio-frequency radiation lasers, masers, and sports and recreation.

ANSI Z87.1-2015 provides clarifications to markings on lenses and frames, and seeing that "+" mark on your lenses and frames means the glasses or goggles you're about to wear have been tested for impact resistance and found satisfactory. The "Z87+" marking is like a seal of approval indicating high-velocity impact, and "Z87" alone means basic impact.

What Are the PPE Options for Eye Protection?

There are many different kinds of PPE that provide eye protection. These include safety eyewear, goggles, side shields, brow guards, and eyewash stations, all of which play a prominent role in preventing injury and vision impairment. However, let's take a closer look at safety eyewear because it is one of the primary PPE segments.

Safety eyewear

Safety glasses have evolved from rather mundane styles to super stylish eyewear that can be used after the workday is over. Safety eyewear is available with:

- Anti-fog coatings that are either water based or solvent based to prevent fogged glasses, which is a common eyewear complaint

- Scratch- and abrasion-resistant coatings

- De-centered lenses for enhanced optimal clarity

- Polarized lenses to reduce glare

- HD technology for optical clarity

- UV protection to protect against the sun’s harmful rays

- A variety of tints to reduce glare, screen hazardous radiation, or to provide other task specific filtration

- Filter lenses with a shade number for protection from radiant energy (Note: The shade number indicates the intensity of light radiation that is allowed to pass through a filter lens to one’s eyes. Therefore, the higher the shade number, the darker the filter and the less light radiation that will pass through the lens.)

- RX and bifocal

- Over-the-Glass (OTG) to use with prescription eyewear

- Comfort features, such as rubber nose pieces and temples for a secure and comfortable fit all day long

There are many things to consider when specifying eye protection for your job site:

- Comfort. Many end users are required to wear their eyewear for extended periods of time, so comfort is a critical issue. When a safety glass is comfortable to wear, the worker is more willing to wear it on a regular basis.

- Style/fashion. Because fashion tends to change rather quickly, market participants need to follow the trends and be ready to adjust their product offerings on short notice. A trend to entice end users to wear their eyewear is to offer logo and branded items. Some leading PPE manufacturers offer in-house custom pad printing to brand safety eyewear.

- Price. Price influences purchases and budgets. Many manufacturers offer value, performance, and premium brands to satisfy economic and style demands.

- Protection. The user wants the product to provide the maximum amount of protection from flying debris and hazards, as well as protect the eye from damaging UV rays.

- Specific applications. The right lens color, coatings, and eyewear styles used in the proper job application can enhance the performance and productivity of the user.

- Anti-fog coatings. Anti-fog coatings are either water based (hydrophilic) or solvent based (hydrophobic). The coating is either built into the lens for long-term use and durability or it is a surface coating. If the coating is not built into the lens, the anti-fog coating becomes quickly compromised after multiple cleanings or exposure to abrasion. Water-based coatings are non-toxic and non-flammable, unlike solvent-based coatings, which can be highly toxic. Keep in mind that a good anti-fog solution increases usage of personal protective eyewear, especially since fogged eyewear is the number one job site complaint.

Our Eyes Deserve Quality PPE

Sustaining an eye injury, especially one that leads to permanent vision loss, can have devastating outcomes for the injured worker. Our eyes are truly amazing, and our sight is one of the most developed senses in humans. When vision is impaired, the quality of life and the ability to work experience a drastic and unfortunate decline. Therefore, preventing eye injuries should be a top task on every safety professional's to-do list. Prevent Blindness America, the nation's leading volunteer eye health and safety organization, says that "90% of all workplace eye injuries can be avoided by using proper safety eyewear."

This article originally appeared in the June 2017 issue of Occupational Health & Safety.