Identify, Verify, and Comply: The Three Pillars of a Successful Electrical Safety Program

What's shocking is that many workers are not using rubber insulating equipment because they simply don't know they need it.

- By Richard A. Rivkin

- Jun 01, 2017

In today's day and age, power is not only a convenience, but a physiological need. People need power to function—we depend on it, businesses depend on it, and industry depends on it. The demand for electricity has been significantly high as a result of various factors such as economic growth, technological advancements, and increase in population over the past few decades. And while the need for reliable power delivery only continues to grow, so does the size of electrical market, as well as the pool of workers on or near energized equipment, thereby increasing the size of the electrical safety market.

The global expansion of energy transmission and distribution network, the trend of industrial automation, and industrial safety regulations are the primary factors contributing to the growth of this market. Moreover, the danger of workplace exposure to electrical hazards continues to increase as workers' responsibilities expand to include interaction with electrical equipment. In reality, almost every single facility has a need for electrical safety as maintenance workers, janitorial staff, facilities staff, and equipment operators all risk exposure to electrical shock. There is quite a large number of possible end users. As such, awareness is paramount—not only about the requirements for use, but also about the requirements for in-service inspection and testing of rubber insulating equipment.

Identifying the Need for Electrical Safety

Arc flash and electrical shock injuries continue to pose a significant threat to workplace health and safety. Anywhere from five to 10 arc explosions occur in electric equipment every day in the United States, and as many as 10 United States workers are killed or injured according to CapSchell Inc., a Chicago-based research and consulting firm. Moreover, the risks associated with shock and electrocution from inadvertent contact with energized parts have also long been recognized as a danger to workers, and they aren't going away any time soon, if ever. According to the Bureau of Labor Statistics (BLS), electrocution is the fifth-leading cause of workplace fatalities in the United States, with more than 2,000 fatal and more than 24,000 non-fatal electrical injuries reported in the past 10 years. Because BLS counts arc flashes as burns rather than in its electrical shock statistics, the true rate of electrical shocks is even higher. Furthermore, OSHA estimates that 80 percent of electrically related accidents and fatalities involving "Qualified Workers" are caused by arc flash/arc blast.

OSHA rules and the NFPA 70E standard make the use of rubber insulting products mandatory when even the smallest probability of contact with 50 volts AC or higher exists. Regardless of the heavy fines, serious injuries, and deaths that occur from arc flash and electrical incidents, compliance continues to remain an issue. What's even more shocking is that many workers are not using rubber insulating equipment because they simply don't know they need it.

While the best way to prevent arc or electrical incidents from happening is to de-energize equipment before beginning work, there are instances where turning off the power could create an even greater hazard. As such, employers and facility owners must establish safe practices to protect their workers against arc flash incidents, including the use of personal protective equipment (PPE).

Rubber insulating products such as gloves, blankets, sleeves, line hoses, and hoods used by electrical workers today are manufactured in accordance with industry consensus specifications under the auspices of ASTM International. These ASTM standard specifications are referenced in the OSHA regulations dealing with electrical safety, specifically 29 CFR 1910.137 covering Electrical Protective Devices and 29 CFR 1910.269 covering Electric Power Generation, Transmission and Distribution.

Bear in mind that rubber gloves are the only protective gear designed for constant contact with, and protection from, energized conductors and equipment. All of the other items are designed for protection from accidental, incidental, or brush contact.

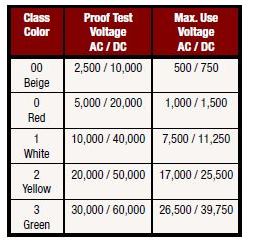

Take care to choose the correct rubber insulating glove for the task at hand and the level of electrical exposure. Rubber insulating gloves are typically manufactured in sizes 8-12, often in half sizes, and some manufacturers also offer gloves as small as size 7 and as large as size 13. In addition, rubber insulating gloves are available in different cuff lengths of 11, 14, 16, and 18 inches, depending on the glove class. Rubber insulating gloves are available in six specific voltage classes (Class 00 to Class 4), and other rubber insulating products are available in different voltage classes, as well.

These are all AC voltages. The ASTM standards also include DC test and maximum use voltages.

There is a significant margin of safety between the proof test voltages and the maximum working voltage. Gloves and other rubber insulating products must be permanently marked to indicate the voltage class, and the gloves and sleeves must also have a color-coded label identifying the voltage class.

Verifying Product Integrity with Visual Inspection

OSHA and ASTM standards also require regular inspection of in-service electrical protective equipment in order to maintain compliance and ensure the products’ safety and integrity when exposed to a wide range of voltages. Visually inspecting rubber gloves and sleeves identifies physical, chemical, or ozone damage. Direct light is recommended because it enhances the ability to see surface imperfections on the rubber. Inflating the gloves with air or otherwise stretching the surface helps identify age and ozone damage as well as other physical damage, such as snags, rope burns, deep cuts, and punctures.

Expand the gloves no more than 1.25-1.50 times their normal size. Listen for escaping air to detect holes. If a portable inflator is not available, use a rubber glove inspection tool or roll the glove cuff tightly to trap air inside. Then, apply pressure to areas of the glove to inspect for escaping air. Repeat the procedure again with the rubber gloves turned inside out.

All rubber insulating equipment should be thoroughly inspected prior to use. Common problems to look for include the following:

- Cracking and Cutting—Prolonged folding or compressing can cause this type of rubber damage.

- UV Checking—Storing in areas exposed to prolonged sunlight causes UV checking.

- Chemical Attack—Oils and petroleum compounds can cause swelling of the rubber.

- Avoid Folding—The strain on rubber at a folded point is equal to stretching the rubber to twice its length.

- Snags—Wood, metal splinters and other sharp objects can snag or tear rubber.

- Physical Damage—Rope burns, deep cuts. and puncture hazards are cause for rejection.

Perform Electrical Testing for Continued Compliance and Cost Savings

Various ASTM Manufacturing and Acceptance standards mandate the testing of the rubber insulating products by the manufacturer or supplier prior to the first delivery to the end user. Users also have the option of performing or requiring an acceptance test upon receipt of the goods and prior to placing rubber insulating products into service. Once placed in service, there are periodic retest intervals specified in the following ASTM standards:

- ASTM F496 Rubber Insulating Gloves –6 months (under very limited conditions this can increase to 9 months)

- ASTM F496 Rubber Insulating Sleeves—12 months

- ASTM F479 Rubber Insulating Blankets—12 months

- ASTM F478 Line Hose & Covers—when field inspection or company policy warrant

These in-service retest intervals are the maximum permitted and in addition to the daily field care and inspection. It is quite common for users, including power utilities and contractors, to specify shorter intervals. However, do not place rubber insulating products into service unless they have been electrically tested within the previous 12 months.

Rubber goods should be electrically tested at their rated test voltage using specialized equipment designed to gradually increase the voltage to the desired test level. The dielectric test is two-fold: pass/fail on the ability to withstand the rated test voltage and, for gloves, quantitative on the ability to prevent electric current from passing through the rubber goods above the maximum contained in the specifications. Products passing the inspection and test procedures can then be returned to service.

Testing is a critical component to electrical safety in that not only does it help maintain compliance, but it also helps to increase savings. Rubber insulating products are costly, and many times these costs are unnecessarily increased by purchasing replacements for products that could have remained in service with the proper testing and recertification.

If you do not have the equipment required to perform these electrical tests, there are independent testing facilities that can perform the acceptance and in-service testing on behalf of end users. ASTM standards recommend that the inspection and testing process include the following steps:

- Check-in

- Removing previous testing marking

- Washing using cleaning agents that will not degrade the insulating properties

- Visual inspection of all services (inside and out)

- Electrical test

- Final inspection

- Recordkeeping

- Marking

- Packing in appropriate containers ("appropriate containers" means boxes, or similar sturdy packaging materials to prevent folding, creasing or similar loose storage that can cause stress on the rubber) for storage or shipment

When selecting a test lab for use, make sure that it is a NAIL-accredited test lab. NAIL stands for National Association of Independent Laboratories for Protective Equipment Testing (www.nail4pet.org). It incorporates the only Laboratory Accreditation for the electrical equipment test labs program in North America. NAIL4PET helps develop uniformity in testing and works in close association with ASTM International.

Conclusion

Nearly all industrial workplaces have a need for electrical safety, and failure to comply can result in heavy fines, serious injuries and even death. Furthermore, OSHA and ASTM standards also require regular inspection and testing of in-service equipment in order to maintain compliance and ensure the products' safety and integrity when exposed to a wide range of voltages. Fortunately, there are practices that you can easily implement into your electrical safety program that prevent injuries, citations, penalties and superfluous spending. It starts with awareness of the need for electrical safety, utilizing visual inspection as the first line of defense for your electrical safety products and periodically re-testing rubber insulating equipment for continued confirmation of effectiveness.

This article originally appeared in the June 2017 issue of Occupational Health & Safety.